|

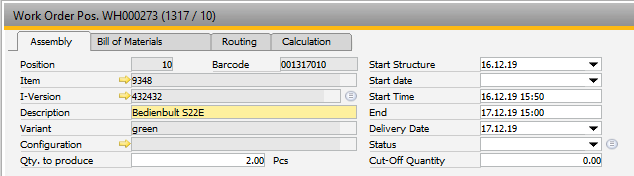

The Positions tab contains all the items that are going to be produced in the work order. In the production position, the data of the assembly to be manufactured is defined. Window settings and Templates are supported.

PATH: Production > Work orders > "Open" work order > Work order document "Positions" tab > "Open" selected work order position.

Window fert_ftpos_edit.psr

The list is loaded completely and is sorted by structure by default. Sorting by SQL (e.g. Template settings) is ignored.

Only the DataWindow sorting (e.g.: via right-click on header) is allowed.

Sorting by structure is saved in column "Structure Pos".

|

|

|

|

Position

|

It can only be changed when the position is created. Beginning and end of the range can be set up in the Configuration Wizard.

The definition of the position number can be manipulated using the following function: workordermanagement.precreatebelpos()

Example:

workordermanagement.src (in Project folder)

// For Items Axxx use Position 100, 101...

// for all other: 200,201...

function precreatebelpos

// aviable:

// e_belnr_id, e_belpos_id, e_itemcode, e_project

if <e_itemcode,left 1> = A then

setvar=ll_group=100

else

setvar=ll_group=200

end if

select <ll_group> + ifnull(max("POS_ID"),0)+1 &

into e_pos_id

FROM "BEAS_FTPOS" &

where "ItemCode"=<e_itemcode,dbstring>

end

|

field: BEAS_FTPOS.BELPOS_ID

|

|

Barcode

|

This bar code is printed on documents and it can be entered in various windows for selecting the production assembly. The bar code is automatically generated.

Configuration: xxxxxxyyy

x=Document number, 6 digits

y=Position number, 3 digits

If 6 digits for a document number or 3 digits for position number are not sufficient, counting is continued alphanumerically.

Example for position from 999:

998, 999, A00, A01, A02 .. A09, A0A ..

Bar code for document 28, Position 1050 would be 000028A1E

Example document number from 999999:

999999, A00000, A00001, ... A00009, A0000A ..

The bar code for document 20500100 position 2050 would be ABLYDGAT6

The highest possible document number is 2117316159, the highest possible position number: 34695.

The Bar code can be determined as follows using Beas script:

belnr_id = document number (BEAS_FTPOS.BELNR_ID)

belpos_id = work order item (BEAS_FTPOS.BEPOS_ID)

// generate Barcode

object=ue_fert_tools=barcode=<belnr_id>=<belpos_id>

// show result (variable e_barcode)

messagebox=info$$barcode = <e_barcode>

|

field: BEAS_FTPOS.BARCODE

|

|

Item

|

The item that is produced in the production position. This entry can no longer be changed after saving.

All items with procurement method Make can be selected.

Item needs to be released for production.

If the item is not released, the following error message appears:

prdrel40$Item is not released for production.

See Item master - Release for production

|

|

|

I-Version

|

Version number of the item to be used. When creating a position, the version stored in Item master is used. If it is changed, the item designation, drawing number and, if necessary, BOM and routing are refershed.

|

Description

|

This is the Item Name from the item master data

If you defined an item version and an item name in the item version, then the name of the item version is shown.

If you choose a configuration, Beas executes formulas or inserts a description from the configuration.

See Configuration

|

|

Variant

|

The name of the variant, which can be defined in the item master, is displayed. BOM and routing are dependent on the variant. This cannot be changed.

If a variant is included automatically in extended warehouse settings, see Edit warehouse master data, Variants

|

|

Configuration

|

Id of the product configuration to produce. It is possible to choose one of the existing configurations with the Complete status, if the item has a product configurator definiton.

All External Configurations which were created for the currently selected item are also displayed.

For more information, see Product configurator.

Note: All Configurations created with Beas version 9.3 PL 1 or older have the status "Complete" at all times.

If the product configurator creates the item name automatically, Beas uses the generated item name from the configuration.

(beas 9.3 PL 2)

|

|

Qty. to produce

|

Important: If the assembly quantity is changed, quantities in BOM are recalculated automatically, but the affected sub-assemblies are not. To update these use Work order structure > right-click > second tab > update assembly quantity.

If lot sizes are considered in the sub-structure, adapting the total quantity of all sub-structures is only possible when using the WO refresh function.

Important: It may be necessary to check reservations as there is no automatic check.

|

|

Cut-off quantity

|

Additional demand according to scrap factor and offcut information in the item master data.

See Cut-off > consider cut-off quantity option.

|

Start structure

|

This may differ from the start date of the assembly in case of a multi-level work order, as the sub-assemblies are produced before the main assembly. This field contains the start date of the subassembly, which must be produced first.

|

|

Start date

|

Scheduled start date of the assembly. This can be used to define the planned start date (top assembly only), which is considered by forward scheduling in the APS.

|

Start Time

|

Start date and time of the currently selected assembly. Calculated automatically by forward or backward scheduling.

|

End time

|

Automatically calculated completion date of the currently selected assembly.

|

Delivery date

|

This date refers to the top level of the work order structure. For sub-assemblies, this date does not apply, as the calculated start or end date is used.

If a work order is created from a sales order, the delivery date is set to: delivery date from sales order minus the average delivery time parameter.

Serves as reference for backward scheduling.

See

Configuration wizard > Materials management > Computation > Average delivery time

If this date is changed, and capacity planning is active, the work order is rescheduled, using the last used calculation method.

|

|

Status

|

Status of the assembly. This field is for information only. Status changes must be done by the users, Beas does not change the status automatically.

|

Last Message

|

Information on when the last FDC report was carried out.

|

|

|

|

Add

|

If a new production assembly is created, it is broken down when saved.

For additional information see Item breakdown.

|

|

Remove

|

Delete the assembly and their sub-assemblies including BOM and routing information.

Only those BOM items and routing positions are deleted that are not linked to other documents (Material postings, Order time receipts etc.) If all entries cannot be deleted, the assembly is closed.

If the assembly contains sub-assemblies, these are closed as well. If one subassembly may not be closed, the superordinate assembly is not deleted, otherwise it would not be possible to display it in the structure view.

Assemblies which may not be deleted are closed after all BOM items and routings without links have been deleted. The WIP-account is balanced.

|

|

Reports

|

Opens the reports (macro menu).

|

Preceding entry

|

Displays the previous entry.

|

>>

|

Displays to next entry.

|

Update assembly quantity

|

If the assembly contains sub-assemblies and the order quantity was changed, the requirement of the sub-assemblies are changed. This function calculates the requirement of the sub-assemblies and updates the values.

Details Details

If the quantity of a BOM item is changed, the quantity of the dependent assemblies and sub-assemblies is not adjusted. This is intentional, because in case of a storage related work order the quantity must not be necessarily equal. If the number is to be matched, this can be done automatically using this button.

Note: If lot sizes are considered in sub-assemblies, this function is not executable. In this case WO refresh is to be used.

|

|

Close Document

|

Only possible if the position is not closed yet, and if there are no open time receipts. With continuous stock enabled, further journal entries may be created.

See WIP functions.

If the assembly has sub-assemblies, you can set up whether these are closed as well.

See Configuration wizard.

A work order position can be re-opened at any time.

See re-open WO position

|

|

Re-open

|

Only visible if the WO position has been closed before.

A work order position can be re-opened any time. If then, costs arise and the order is closed again, all costs are posted correctly to the WIP account.

Note: Working with Post-calculation > Reference date function, a work order should not be re-opened, as then the calculation of the reference day would not be possible.

|

|

Refresh

|

BOM and routing are read again from the item master data and the work order is updated. The full sub-structure is updated. Each position is analyzed separately, deleted, replaced, added or completed.

In the selected position, the following fields are updated:

If version control is active, the drawing number and description is taken from the respective version.

If deleting is not possible, the relevant items are completed. The following remains unchanged when updating:

| • | Position number of the assembly |

| • | Information whether assembly was completed |

This button is not available for collective orders, call up from precalculation, new creation of work order, completed position, or if the APS planned switch is set.

The work order can be updated if it was not created from a precalculation, and if it is not a collective order. An update is also possible if time receipts or material postings exist. In this case, each position is analyzed separately, deleted, replaced, added or completed. As long as the operation sequence or the material item number is not changed in the master data, the production item is firmly connected to the master data This makes it possible to update the work order regardless of the manufacturing item number.

The following information is not changed when updating:

| 1. | Item number of the assembly, operation sequence and material item |

| 2. | Deposited bar code number of the assembly, operation sequence and material item |

| 3. | Information on status (completed) |

If an operation sequence or a material item is completed, it is updated, but remains closed. If an assembly is completed, it is not changed anymore and there is no further breakdown or update of the operation sequences, BOM and sub-assemblies.

If in master data a material item (which is an order-related assembly) is deleted, the material item and the associated assembly are also deleted during the work order update. If deletion is not possible due to existing time receipts, only the deletable items are deleted and all related operation sequences, BOM items and assemblies are closed. The WIP account for the affected assemblies is cleared.

Thus, it is always possible to refresh work orders including multi-level work orders. Phantom assemblies do not cause issues.

Material change in the existing BOM:

If the item number in an existing material item is changed in the master data, the link to the production BOM is lost during the update. First it is deleted, then it is inserted as new. A new number and bar code are assigned to the BOM item. If the BOM item cannot be deleted, it is set to completed. The same applies to the corresponding sub-assemblies.

Note: The update process uses the item number in master data. For this reason, BOM and operation sequence position numbers may not be changed.

Refresh only BOM

In the configuration wizard you can define to refresh only the BOM but not the routing. This can be used in case the routing is managed in the work order and not in the master data.

Restrictions:

If the work order was created from a precalculation, a project or maintenance order or if it is a collective order, the refresh button disappears, as no connection between the master data and work order is possible.

If material summary is enabled refresh is not possible. If you click the button, the error message (auftrs340) "material summary enabled, no work order update possible" is displayed.

Related option for material summary is in Configuration wizard > Production > Create new > Summarize phantom assemblies by item numbers.

If the Changes allowed flag is not active at the work order position, the Refresh button is not visible. If the Changes allowed flag is not active in a sub-position of a current work order position, the refresh function does not refresh the sub-position or any related positions of this sub-position.

Note on split assembly: If an assembly was split, (see split assembly) , the split assembly is not updated any more. The quantities of the original assembly are changed back.

Variant production

If variant production is used, parameters can be queried when an item or work order is created. These are saved and used in case of an update, they do not need to be entered again.

(Table beas_ftcaft_varentry). For more information see function Variable.

Multiple update

In the work order list several orders can be marked and calculated at once. The drawing number, description, DIN, raw material and match code of the selected assembly are NOT updated. See WO structure.

|

|

Post-calculation / Product Costing analysis

|

A post-calculation on the current assembly can be created.

|

Journal of entries

|

Opens the transaction journal

|

Inventory history

|

Opens the inventory history of the assembly.

|

Variable

|

If variables were created manually for variant production, they are saved in table beas_ftcaft_varentry.

You can edit or delete the variables. If the work order is updated, existing variables are used, a new entry is not necessary. To enter new variables, delete the old ones first.

|

Protocol

|

Opens protocol.

|

Formulas recalculate

|

This function is used, for example, after formulas have been updated. Fields like lead time can be recalculated.

Only those formulas and tables are affected which are stored directly behind a field. Scripts are not executed.

The structure cannot be manipulated, e.g. by exchanging a material item.

BOM items cannot be activated or deactivated.

The following cannot be computed:

| • | Designation or description of the operation |

| • | BOM – Material requirement |

| • | Material-dependent breakdown |

No rescheduling, re-dispatching or correction of reserved times is performed.

|

If variant production is used, parameters can be queried when an item or work order is created. Variants are saved and used in case of an update, they do not need to be entered again.

(Table beas_ftcaft_varentry). For more information, see the Variable function.

|

In work order list several orders can be marked and calculated simultaneously. See WO structure .

|

|

Help URL: https://help.beascloud.com/beas202102/index.html?fertigungsposition.htm

|