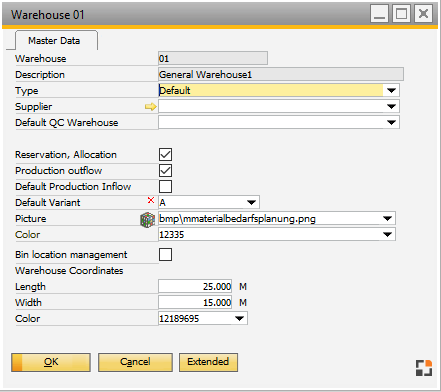

Master data tab

This window is accessible via Warehouse Management as well as SAP Business One > Definitions > Warehouse > Button Extended

PATH: Inventory > Warehouse Management > Master Data > "Edit" an entry.

Window bin_whs_edit.psr

Field |

Meaning |

||||||||||||||||||||

Warehouse |

|

||||||||||||||||||||

Description |

Name of the warehouse. |

||||||||||||||||||||

(Warehouse) Type |

|

||||||||||||||||||||

Supplier |

|

||||||||||||||||||||

Quality Control warehouse |

For each warehouse a goods receipt warehouse can be defined separately. This setting has a higher priority than the setting in the configuration wizard.

Note: In advance, at least one goods receipt warehouse needs to be defined (type of the warehouse = goods receipt) If there no warehouse is selected, setting apply according to Configuration wizard - quality control.

See |

||||||||||||||||||||

Reservation, Allocation |

|

||||||||||||||||||||

Production outflow |

|

||||||||||||||||||||

Default Production inflow |

If active, this is the default warehouse for receipt from production. If a warehouse is defined as receipt warehouse, every assembly which is posted in (backflushing, posting with last time receipt, etc.) will be posted to this warehouse. Only one production receipt warehouse can be defined. If no warehouse is defined as standard receipt warehouse, the warehouse defined in item or work order is used. Settings accessible also via Configuration wizard |

||||||||||||||||||||

Bin location management |

|

||||||||||||||||||||

Default variant |

|||||||||||||||||||||

Length |

Specifies the length (meters) of the storage area (only for visualization if beas bin management is activated). |

||||||||||||||||||||

Width |

Specifies the width (meters) of the storage area (only for visualization if beas bin management is activated). |

||||||||||||||||||||

Color |

Defines the background color for visualizing the storage area. |

||||||||||||||||||||

Picture |

Select an image |

Button |

Meaning |

|

Extended |

Open SAP Business One warehouse master where additional Beas features are available via right-click.

Note: The "Drop-ship" SAP function is not supported in Beas Manufacturing. |

Right-click menu

Button |

Meaning |

|

Extended |

Same function as the button (see above). |

|

Change log |

Open protocol. |

|

Support |

Open Beas error messages. |

|

Deactivate bin location management |

Only displayed when dealing with a bin location warehouse. After a security query the following happens:

|

If the selected warehouse has bin locations, additional tabs are displayed

Storage area |

Definition of storage areas Below: Definition of bin locations See

|

|---|---|

Extended |

Scripts for extended visualization See |

back to Warehouse master data