|

APS means Advanced Planning and Scheduling. The APS extends the planning functions of the beas Basic license with further functions for detailed planning.

New or existing work order positions are calculated by using predefined calculation types.

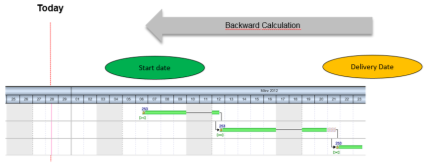

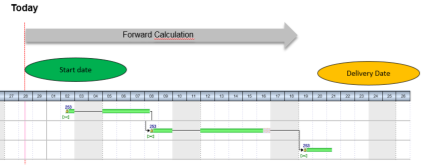

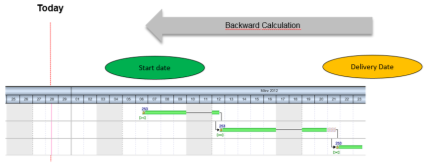

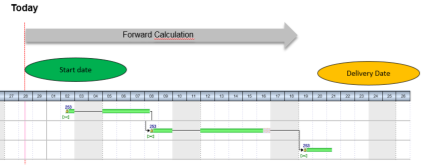

Depending on the calculation type, the work order positions are calculated forwards or backwards and the material availability will be checked. The work order then is automatically scheduled, while considering the resource limits. The calculation can be done forwards, starting from a start date (resource-optimized) or backwards, starting from a delivery date (stock-optimized). The calculation type is used to reduce the transition times in two steps.

In a calculation type, various parameters are defined to control the behavior of the calculation:

- the scheduling direction

- the consideration of material receipts

- buffer times.

There are five (5) default calculation types in beas. See Default Calculation Methods. Besides using the predefined calculation types it is possible to create your own in APS.

Define calculation types under: Production > Capacity planning > APS Calculation type. In the planning settings (Production > APS > Edit scheduling) you can configure which calculation method is available in this plan. If a new calculation method is defined, you must remember to store this in the planning, as well.

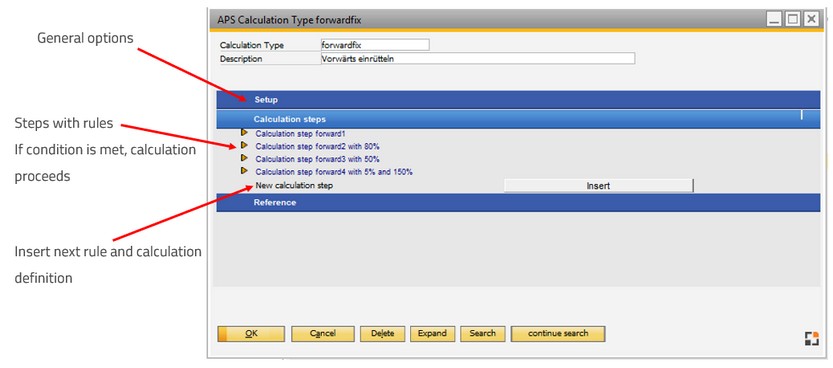

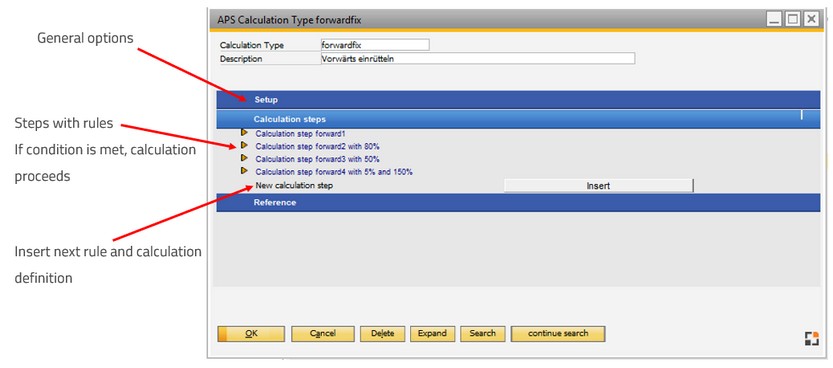

A calculation method has the following structure:

Window fert_xgantt_methode_edit.psr

To facilitate configuration, the setting is specified using a wizard. The settings are well-documented there and can generally be made without documentation.

Master data

Window system_option_struktur.psr

Field

|

Description

|

Calculation type

|

Unique ID, the name of the calculation type.

|

Description

|

Description of the calculation type.

|

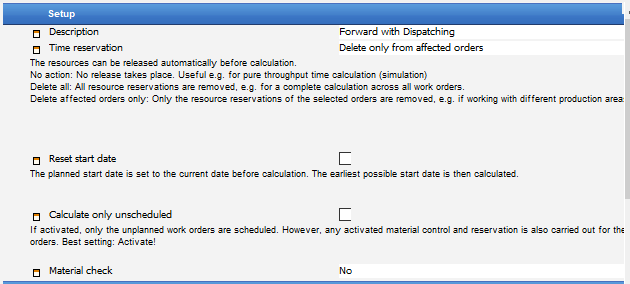

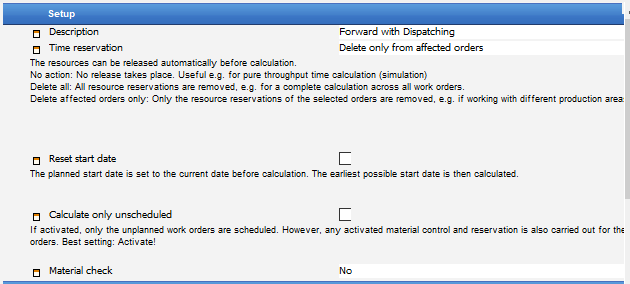

Time reservation

|

Delete all: All time reservations are deleted before calculation, including those from not visible and previously planned work orders. All resources are available to the new work orders to be dispatched.

Work orders that are not recalculated, do not have any time reserved.

Delete only from affected orders: This option is the standard setting to be used Only the resources of the orders that are recalculated are removed. This ensures that the resources of previously planned orders are retained except the resources of fixed positions.

No action: Time reservations are not removed. As a result of which the times cannot be calculated optimally or by priority.

|

|

Reset start date

|

If activated, the planned start date is set to the current date before the calculation. The earliest possible start for a production structure is then calculated.

|

Calculate only unscheduled

|

If activated, only the unplanned work orders are scheduled. However, any activated material control and reservation is also carried out for the planned work orders. It is recommended to enable this option.

Work orders marked for calculation, but not calculated due to this setting, receive the "fixed" value in field "last calculation".

|

Material check

|

A material check can be activated which reserves the material stock or all planned accesses for the work orders by priority (soft reservation).

A copy of the warehouse stock of goods issues is created and these are then assigned to the work orders by priority (sorting of the production list). If no planned issue is available, a possible issue is used: current day + lead time of the item in question.

Note: The material check is only performed if the calculation is started in the APS view (List). For a material check, the entire production must always be seen, and the previously planned work orders must be considered. For this reason, it is important that all work orders planned and to be planned are displayed in the list, and that the previously planned work orders are at the start of the list. In this manner, during the material check the Only calculate unplanned option is ignored for the material check itself.

Only items with positive stock inventories, which are not blocked and are released from Beas side, are taken into account.

If a material is unavailable for a work order, this is displayed in the Gantt chart using a symbol. The missing material and the planned receipts can also be displayed in the list display and the Gantt chart.

After scheduling *1

In the material calculation after scheduling, the latest possible material receipt is calculated. The material is not correct if the previously calculated start date of the position cannot be fulfilled.

Before scheduling *2

In material calculation before scheduling, the earliest possible material receipt is calculated irrespective of the required date and this is entered as the earliest material receipt in the position.

If Consider material entry is activated in the calculation step, the material entry determined here is considered and the operation is only started if the material is available. This only works for forward scheduling.

If the missing material is an assembly (not order related) and there is already a work order, this assembly and this work order has a lower priority according to APS y View > Production List, the priority is changed automatically, i.e. the work order is moved up in the list. If Consider material entry is activated in the calculation step, it ensures that the sub-assemblies are always scheduled before the higher-level assemblies.

Pre- and post-scheduling

Under certain circumstances, it may be logical to activate both variants.

Important:

The "earliest possible start date" information is overwritten in the operation with "latest possible".

Notes on material control:

| • | A stock reservation has always higher priority (beas 9.3 PL 2 HF 4) |

| • | Order-related assembly BOM items are completely ignored, because it is assumed that the associated manufacturing position exists in the same amount. The system ignore higher or lower quantity sub-assembly

Reservation between bill of material position and work order positions are ignored. |

| • | Material requirement coverage is tested as follows: |

| o | Does a planned production receipt exist? (* 2) |

| o | Check only Stock, which not reserved |

| ▪ | Earliest production receipt ? (* 1) |

| ▪ | Earliest purchase order ? (* 1) |

| ▪ | Earliest replenishment date ? (* 1) |

| o | Temporarily Reservations (late as possible, for material control after dispatching) |

| ▪ | Latest possible production receipt, completed before the requirement date |

| ▪ | Latest possible purchase order receipt |

| ▪ | Earliest production receipt - possibly at a later date? (* 1) |

| ▪ | Earliest purchase receipt - possibly at a later date? (* 1) |

| ▪ | Earliest replenishment date? (* 1) |

(* 1) Special features of this calculation steps:

In "Material check after scheduling" "too late" is active if the planned receipt is over the requirement date. The requirement date is the calculated completion date or the start date of the assigned work order. The planned receipts are assigned to the position and can be represented in the GSP list.

(* 2) Only with "material check before scheduling":

If a work order is determined, it is first scheduled. This ensures that the work order is finished earlier and can cover the requirements as soon as possible.

Consider WareHouse

| • | Negative Stock is not allowed. |

| • | Ignore locked Warehouses. |

| • | Type not "Blocked WareHouse" |

| • | Reservations always have the highest priority. |

| • | If a locked batch is in a production warehouse, then the batch number is available for production. |

| • | Item Versions not considered (no check on Batch/Serial number level) |

Material linked to external routing positions

Material positions linked to an external routing position can reserve quantity which is available in an external warehouse.(beas 9.3 PL 2 HF 4)

|

|

Calculation steps

Any number of calculation steps can be defined.

Calculation step

|

Unique ID

|

Sorting

|

Sequence. By default, this value is set to “2”. If the user inserts a new calculation step (last field in this section), the system creates a new sub section “Calculation Step 3 3” adding 1 to the previous counter in the Sorting and Description fields.

|

Description

|

Description of calculation step.

|

Execution condition

|

Always

|

The step is always executed.

|

Date > Delivery Date

|

The calculation step is executed only if the calculated end date is after the delivery date.

|

Date < Start Date

|

The calculation step is executed only if the calculated start date is before the stored start date or in the past.

|

This system can be used to perform for example a re-allocation:

Step 1: Calculation using default (forward).

Step 2 and following steps: Reduce transit times, increase overload and calculate again, and try to adhere to the delivery date in this way.

|

|

Scheduling Direction

|

Backwards

|

Backward from delivery date, material-optimized.

Fixed operation specifications are not considered.

|

Forward

|

Forward from start date, resource-optimized.

|

Catch Up

|

Forward from present, only operations in the past and overlaps are moved. Idle time, transit time and fixed operation specifications are not considered for the work sequences in question.

|

|

|

Latest start

|

The system tries to start as late as possible but uses only forward calculation.

Beas calculates forward. If the calculated end date is earlier than the delivery date, Beas calculates again with another start date. If end date is too late, Beas attempts the same calculation with an earlier start date

Use this if you want to work with material optimization and if you need forward calculation.

|

|

Consider scheduling ID

|

If you do not filter out planned production orders in the planning view, you can also define the use of the planning flag using the calculation step.

Planning indicator Delete

|

All flags are removed and calculation is performed.

|

at Planned not Calculate

|

No calculation is performed.

|

Always Calculate and Set

|

A calculation is performed and the flag is always set afterward.

|

|

|

Work step fixation

|

All Delete

|

All fixed specifications are removed on calculation

|

Delete incorrect only

|

Fixed specifications that are in the past are removed. Fixed specifications producing a date overlap are not removed.

|

|

|

Consider material entry

|

If this is activated, the receipt date calculated from the material control is used at the earliest start date for the affected positions. However, this does not affect fixed positions.

|

Fix logged task

|

Specify how currently reported positions are treated. If an operation is in work (started) and a calculation is started in APS, the operation is not moved. The position is fix. Only applies to forward scheduling.

|

Simulation

|

The calculation is performed as a simulation, which means that calculated times are not reserved or written to the reservation table and visualization table. Only the start date or end date is calculated. By default, this option is unchecked.

|

Consider capacity limits

|

Enabled: The resource with the enabled "observe capacity limits" option is never dispatched with more than 100%. All time reservations are considered, even work orders which are not currently calculated.

Exceptions:

| • | Operations are fixed manually in APS |

| • | The "observe capacity limits" was disabled in resource |

| • | "Overlapping limit" setting in the calculation type was set to more than 100% |

Disabled: Resource limits are not considered. Calculating work orders, time reservations of other work orders are not taken into account.

|

|

Consideration of time receipts

|

Reported times

|

The previously reported times are deducted from the planned time and used for further calculation.

|

Reported amounts

|

The proportional time of the reported quantities (quantity specifications via the time reports) are deducted from the planned time and used for further calculation.

|

Not considered

|

The planned time is always used for calculation, regardless of the previously reported times or quantities.

|

|

|

Exploit the full capacities

|

Disabled: Detailed planning Disabled: Detailed planning

Beas applies this calculation method only if the following conditions are met:

| • | Both the APS Calculation method and the work order priority are set to 100% |

| • | In the routing of a work order the operation is set as Simple utilization / or Percentage = 100% |

| • | The resource linked to each of the routing positions of the Work order is set to have the master data field Number of machines/Pers = 1. |

How Detailed planning works:

The detailed planning checks to the minute when a resource is available, and whether the work sequence can be completed in the available time windows.

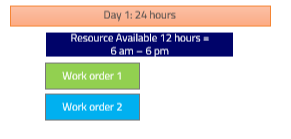

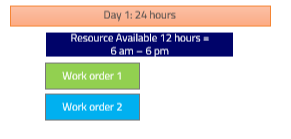

Assumptions: our resource is the same on all routing position on the below reported examples and has a total capacity of 12 hours per day.

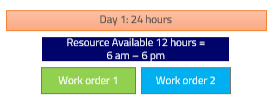

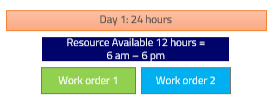

Example 1:

Work order No. 1 and Work order No. 2 start at 6am on the same date/time. Both work orders only have one routing position and each position has an entire duration of 6 hrs.

The result of an APS forward scheduling will be: Work order 1 starts at 6am, Work order 2 starts at 12pm because between 6am and 12pm the resource is not available and is occupied by work order No. 1.

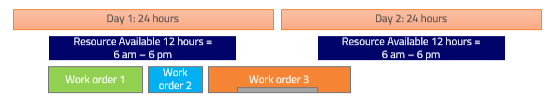

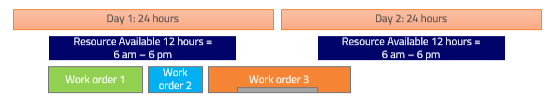

Example 2:

Work order No. 1: one routing position with a duration of 6 hours,

work order No. 2: one routing position with a duration of 3 hours and

work order No. 3: one routing position with a duration of 6 hours.

The result of an APS forward scheduling will be:

Work order No. 1 will start on day 1 at 6am,

Work order No. 2 will start on day 1 at 12pm,

Work order 3, even if you have set the same start date/time for the APS forward calculation, will be moved forward to start on day 1 at 3pm but will finish on day 2 at 9am.

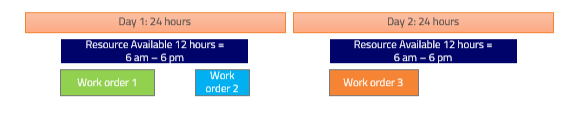

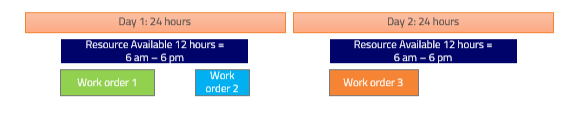

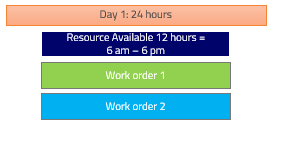

Example 3

Work order No. 1: one routing position with a duration of 6 hours,

work order No. 2: one routing position with a duration of 3 hours and

work order No. 3: one routing position with a duration of 6 hours.

ATTENTION: The following example assumes that you are working on the APS Gantt and you have set work order No. 2 manually (by dragging it on the Gantt chart) to start at a specific time (and the operation is also then fixed by APS).

In this example, Work order 3 can start only start on the second day, because between Work order 1 and Work order 2 the free time is not enough.

See Capacity planning - APS, Exploiting the full capacity

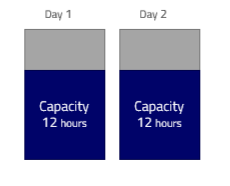

|

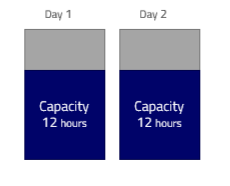

This method checks the total available capacity on a day for a resource.

Note: It does NOT check when the capacity is available.

Example 1:

2 work orders, one routing position per work order, each routing position with a total duration of 6 hours. Both work orders are planned in APS with forward scheduling and with the same start date/time.

The result of an APS forward scheduling will be:

Both work orders will have the same start date and time because Work order 1 needs 6 hours and 6 additional hours are available for Work order 2. The start/end time of each work order is not checked by Beas.

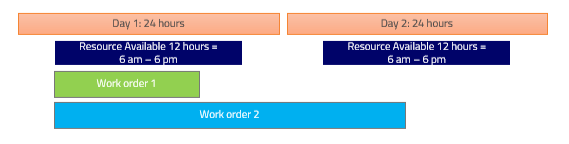

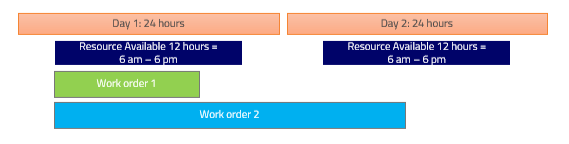

Example 2:

2 work orders, one routing position per work order, each routing position take 8 hours. We have a total duration of 16 hours for both work orders with a total available capacity of 12 hours on the machines.

The result of an APS forward scheduling will be:

Here again both work orders start at same time but the time span by which Beas assigns the second work order is longer. The routing operation of the second work order will still be 8 hours (as well as the capacity occupied on the resource), but can take only 4 hours from Day 1 and will have to take 4 hours from the second day. This is why you will have representation in the APS GANTT for the second work order that is longer than the first one. If you check the Resource > Dispatches > Detail, you will see the calculated time zones for the second work order: Day 1: 6am – 10am ( 4 hours, as the remainder of the capacity has been taken by work order 1) Day 2: 6am – 10am (the remaining 4 hours of work order 2)

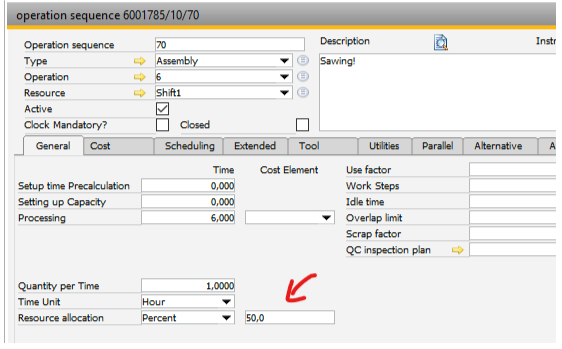

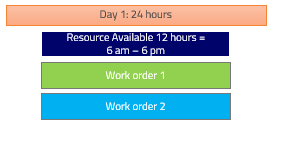

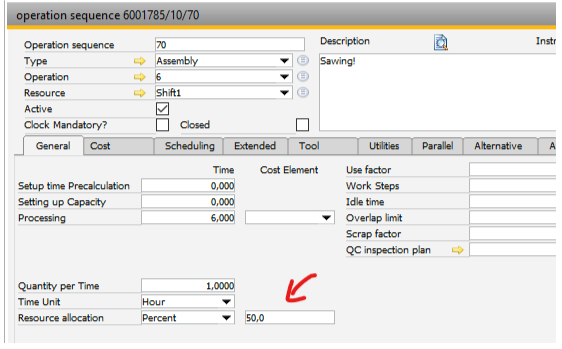

Example 3:

Work order 1 and 2 have been set to start on the same Day by APS with forward scheduling. Each of the work orders has one routing position and each of them lasts for 6 hours. You have assigned a resource allocation of 50% for each of the routing positions.

In this situation, the Detailed planning will not be used.

The result of an APS forward scheduling will be:

The system plans the complete day, but on both work orders it will have the same start date/time, and they will be in parallel because of the 50% setting at the routing position resource allocation. The system will represent both work orders with a longer time span (12 hours each), but each of them will still occupy only 6 hours of resource capacity.

See Capacity planning - APS, Detailed planning

|

|

|

Transit time in %

|

Specifies the % of transit time to be considered.

By default it is the stored priority setting according to the production order.

A percentage value can be entered. The lower the value, the lower the throughput time is.

See Transit time.

|

Capacity overload limits in %

|

Specifies the percentage the resource may be overloaded by.

Example: If the resource has a planned capacity of 8 hours / day and 150% is set, the order can schedule this resource for 12 hours.

By default it is the stored priority setting according to the production order.

A percentage value can be entered. The lower the value, the lower the throughput time is.

|

External operation: Consider goods receipt from PO

|

Note: Only adjustable for forward scheduling.

| • | If there is no purchase: The finishing date is calculated based on the deposited job times (if time calculation is active). Then, the idle period is added. |

Note: idle time is often used for calculating the lead time.

| • | If there is one open purchase: The finishing date is delivery date + time of day as per calculation setting. Idle time is ignored (see above). |

| • | If there are several open purchases: The finishing date is delivery date + time of the first purchase + time as in calculation settings. |

| • | If start date of the operation is after delivery date: The finishing date is the same as start date of the operation (0 processing time) idle time is set to 0. Only transit time is taken into account. |

See External production - Delivery date determination / Lead times

|

|

External operation: Time of inflow

|

This option is available only if the field External Operation: Consider Good Receipts from PO is checked. At purchase only the date can be entered, not the time, so an default time (standard: 3pm (15:00)) is defined. The usual warehouse delivery time should be entered.

|

Set work sequences logged in

|

If a work sequence is currently logged in and this option is active, the start time for this work sequence is ALWAYS the present. This only works for forward-scheduling.

|

Reference

Report

|

Enable to make the calculation type as available in APS list view. By default, this option is unchecked.

|

Gantt Display

|

Enable to make the calculation type as available in the Gantt display. By default, this option is unchecked.

|

Choose calculation type Choose calculation type

Help URL: https://help.beascloud.com/beas202102/index.html?berechnungsarten.htm

|