|

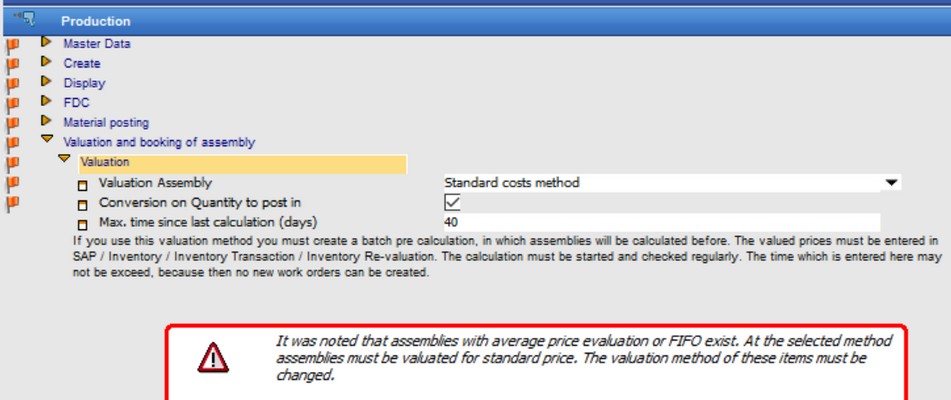

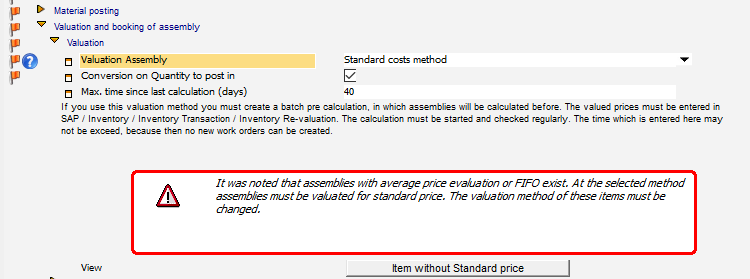

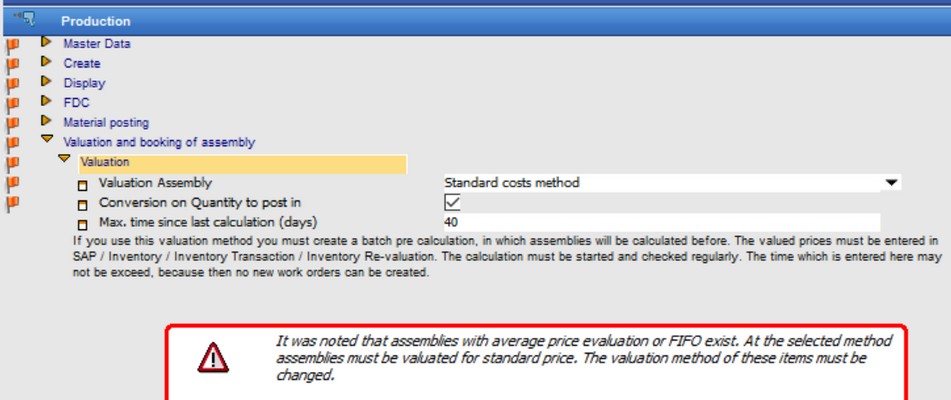

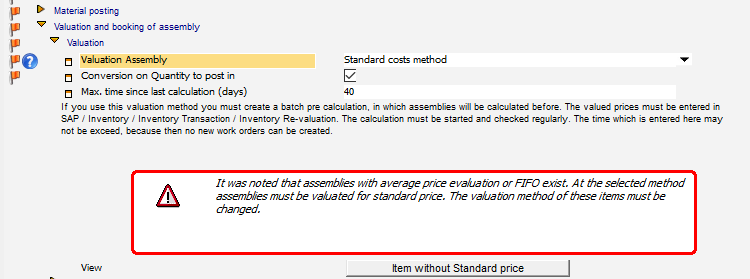

PATH: Administration > System Initialization > Configuration wizard > Production > Valuation and Posting of Assembly.

Webinar Product cost determination Webinar Product cost determination

Valuation Method

|

Description

|

Valuation Assembly

|

Option

|

Which costs are used?

|

As Manual transfer

|

It is posted at a fixed price. See Pricing types.

|

Production planned cost

|

Partial and final posting at planned costs

Problems related to valuation at planned production costs Problems related to valuation at planned production costs

With this method, items are valued at the Precalculation price. The Precalculation (single step, based on the production assembly) is performed at the moment the assembly is posted in, . That way it is ensured, that the Precalculation is up to date.

Which price to be used from Precalculation can be set up in Pricing > Valuation.

Precalculation is performed via concurrent post-calculation. Accordingly post-calculation settings apply.

Valuation of material

In the Configuration wizard > Calculation > Post-calculation > "value planned costs" the valuation of material can be set up.

Precalculation price (Standard): In this case the price is used from Precalculation, from which the work order was created. Or as per Precalculation pricing at the moment of work order creation.

Note:

Depending on how much time passed between Precalculation and creation of the work order, the price may be outdated.

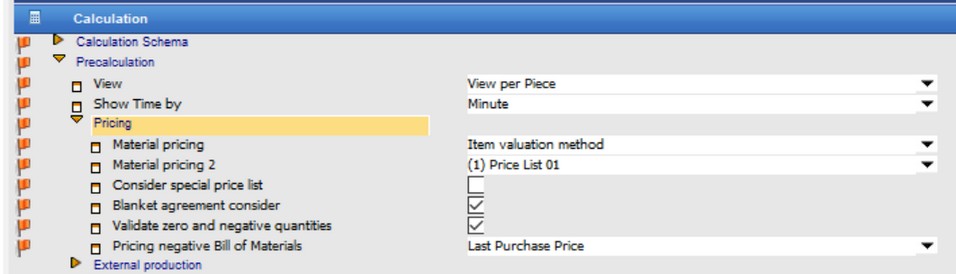

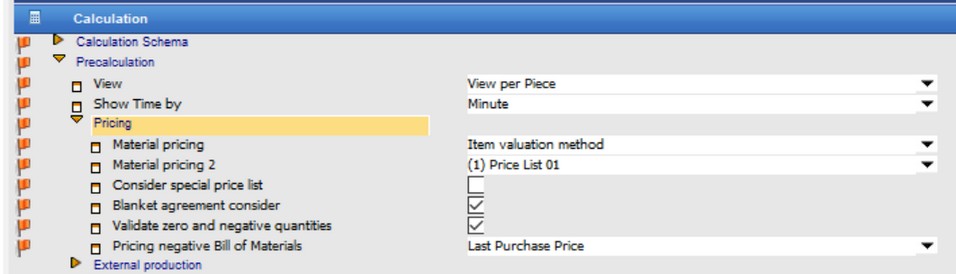

Setup in Calculation > Precalculation > Material pricing.

If in Manufacturing > View > BoM the option "Prices changeable" is enabled, the determined price can be viewed and changed in the production BoM item.

Posting price:This option makes sense if the value of the assembly is dependent on the material value. In this case, the price will be determined on the basis of the material price of the last issue on the respective material. Here, not the sum of the posted values is determined, but the price per unit is multiplied with the planned quantity. Then, the value of the assembly is not affected by scrap postings.

Last purchase price, calculation price, moving average, etc.: Depending on the settings, the current entry at the date of valuation is used for valuing the material. Unlike the valuation at post-calculation price not the actual costs are used for the valuation but the planned cost, with appropriate current material prices. This valuation method is recommended, but requires correct planning data (production times, quantities of material, etc.).

|

|

Standard costs method

|

The production order is firmly connected to the batch-Precalculation. For this reason, the batch-calculation and the pricing procedure (item valuation method - item at standard cost) are mandatory.

See standard cost method

Concept:assembly valuation

WO items

|

Note: For standard cost items, no matter which valuation is selected, postings are always performed at standard costs.

In Work order a production type can be stored. In the production type a valuation method can be entered. This valuation method has a higher priority than the method selected here.

See Production types

Additional valuation methods are available in expert mode only.

|

|

Conversion to posting quantity

|

(Active by default, only visible in expert mode)

This calculation allows a very exact valuation for partial postings

Active:

For partial posting:

posted material and work order times are converted to the completed quantity. This serves as reference for assembly valuation.

At final posting: post-calculation of accrued costs minus the already posted values.

Inactive:

Post-calculation of accrued costs minus the already posted values.

Note:

If the option is disabled and goods are posted at post-calculation price, the actual post-calculation price is used for valuation. This has an effect only at partial postings. Because significant valuation errors can arise due to an incorrect operation, we strongly recommend not to disabled this option.

Projection:

Post-calculation offers a function to calculate the expected costs of a given quantity based on the on previously reported quantities. Costs for material, operations, and quantity, depending surcharges are calculated.

Example:

Operation with costs of 2€/Minute

Planned quantity: 10 pcs

|

without projection

|

with projection for 1 piece

|

with projection for 10 pieces

|

1 minute, 0 pieces reported

|

2 €

|

0 €

|

0 €

|

1 minute, 1 piece reported

|

2 €

|

2 €

|

20 €

|

5 minutes, 2 pieces reported

|

10 €

|

5 €

|

50 €

|

This function is useful for actual costs evaluation methods with partial postings.

Example:

1. Operation planned: 10 minutes, costs 2€/minute

2. Operation planned: 10 minutes, costs 2€/minute

Planned 10 pieces, Partial completion 5 pieces

Planned costs: 1. operation 20 €, 2. operation 20 € = 40 = 4 € per piece

|

without projection

|

with projection

|

1. operation: 10 minutes, 10 pieces reported

2. operation: 10 minutes, 5 pieces reported

|

20 €

+ 20 €

= 40 € : 5 = 8 €/Piece

|

10 €

+ 10 €

= 20 € : 5 = 4 €/piece

|

1. operation: 10 minutes, 10 pieces reported

2. operation: 10 minutes, 10 pieces reported

|

20 €

+ 20 €

= 40 €

- 40 € (of first posting)

= 10 € : 5 = 2 €/pieces

|

20 €

+ 20 €

= 40 € : 10 = 4 €/piece

|

This example shows the difficulties of partial postings without projection. The first 5 pieces are valued at 6€, the next 5 pieces at 2€. In certain configurations even negative evaluations are possible.

Material evaluation example:

A BOM item has a requirement of 1 per 1 assembly and a value of 3€

Production quantity = 10

|

Without projection

|

With projection

|

Material issue total 10 pcs

|

10 * 3 = 30€

|

10 * 3 = 30€

|

first partial posting 1 pc

|

Posting 30€

|

Conversion to planned quantity, in this case 1/10 = Factor 0,1

30€ * 0,1 = 3€

|

second partial posting 1 pc

|

Posting 30€ - already posted = 30€ = 0€ !!

|

Conversion to planned quantity, in this case 1/10 = Factor 0,1

30€ * 0,1 = 3€

|

last posting and order completion

|

Posting 30€ - already posted= 30€ = 0€ !!

|

Not the projection but the accrued costs are used.

30 € - already posted = (3€ + 3€ = 6€) 24 €

|

Webinar Product Cost determination from 2017/06, Part "Quantity Projection" Webinar Product Cost determination from 2017/06, Part "Quantity Projection"

Post-calculation – Concepts

Example: Projection of actual costs

|

|

max. time since last calculation

|

This option is only available if you work with Standard costs method

Using the standard cost method, the total value and the value of the parts of an assembly can be identified, such as materials, manufacturing costs, tool costs, or other surcharge costs. Standard cost means, that these values are not dependent on the volume of the production, only the budget figures are taken into account.

The standard cost method involves an entire workflow:

| • | Pre-calculation via batch pre-calculation |

| • | Pricing on basis of the pre-calculation |

| • | Copy of evaluation into the work order, including the calculation scheme. The work order is now firmly attached to the pre-calculation |

| • | Postings are performed with the current standard cost rate |

Configuration Wizard > Production > Valuation and booking of the assembly > Valuation > Valuation of the assembly by "standard cost method"

The Max time for last calculation field is displayed. This is the update interval for batch calculations. If the entered time is exceeded, no work orders can be created.

A correctly set pre-calculation valuation method is crucial. Set to "Item valuation". Set all items to "standard price".

Configuration Wizard > Calculation > Precalculation > Material pricing to "Item valuation method"

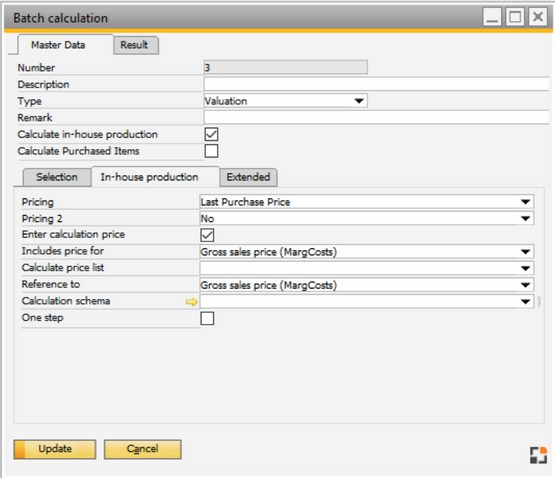

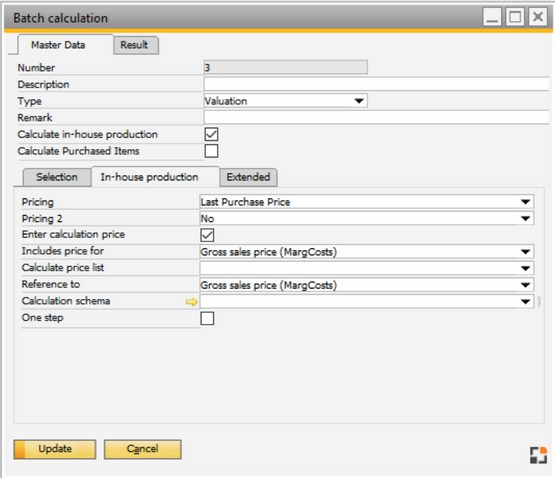

Inventory> Inventory Transaction > Batch calculation

Setup a calculation for calculating standard costs

The price list or price calculation does not need to be filled. Select the desired evaluation method in Pricing and Enter calculation price, and the type of pricing procedure. One step evaluation can be enabled for standard cost.

The defined calculation should be performed regularly and the update interval can be set in the Configuration Wizard. After calculating, change to the results tab and perform an inventory revaluation.

Note: If the price per warehouse is set, the batch calculation needs to be performed per warehouse. See Batch-calculation.

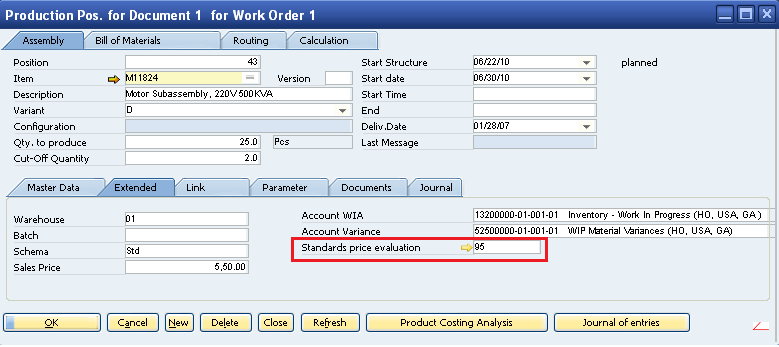

Connecting to a work order

All the work orders that are being created for the items, are referring to the calculated standard costs. The connection to the standard costs calculation is available in:

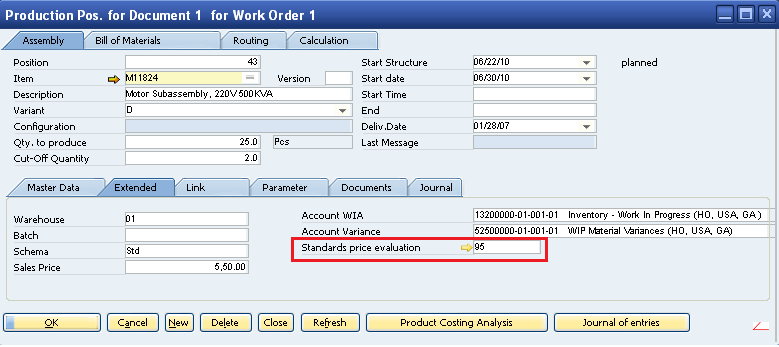

Production assembly > Assembly tab > Extended >Standard price evaluation.

Valuation of assembly – Standard cost method

Concept: Valuation of assemblies

WO positions – Item

Batch-calculation – Standard costs

Affected database fields: Affected database fields:

The following fields are filled:

BEAS_FTPOS.STANDARDCOST_NR = relates to the last calculation

BEAS_FTPOS.SCHEMA_ID = used schema in this calculation

BEAS_OITM_CALCPRICE = calculation result

BEAS_PK_BATCHKALK_HEADER = calculation definitions

|

|

|

Pricing at valuation

|

Visible only when an evaluation form based on a calculation has been chosen. Here is to be determined, which result of this calculation is to be accessed.

|

|

|

Material+Production Marginal Costs

|

Sum of the pure material and manufacturing costs, without supplements

|

Material+Production Full Costs

|

Sum of the pure material and manufacturing costs, without supplements

|

Costs of goods sold Marginal costs

|

According to the calculation scheme in line "manufacturing costs", usually material costs + material surcharges + manufacturing costs + manufacturing surcharges

|

Costs of goods sold Full costs

|

According to the calculation scheme in line "manufacturing costs", usually material costs + material surcharges + manufacturing costs + manufacturing surcharges

|

Costs of sales Marginal Costs

|

According to the calculation scheme in line "primary costs" usually line of COGS + surcharges

|

Costs of sales Full Costs

|

According to the calculation scheme in line "primary costs" usually line of COGS + surcharges

|

Production costs (PLANNED) + Material costs (ACTUAL)

|

Sum production plan costs + material actual costs (beas 9.2 PL: 04)

|

|

|

Precalculation material pricing

|

This setting is a copy of Calculation > Precalculation > Material pricing. Pricing can be selected.

See: Pricing - Types

|

|

Post-calculation material pricing

|

Only visible if as valuation form based on a calculation was chosen.

See: Pricing - Types

|

|

View

|

Press the button to get a list of all items with standard price.

|

Note: Valuation by post calculation price Note: Valuation by post calculation price

At valuations by post calculation price the actually accumulated costs are used for valuing the assembly. This is generally problematic, since it depends on the correct behavior of all users. If, for example order times are not reported correctly, thus the assembly is incorrectly valued. A later correction is not possible. It is recommended to use the valuation by standard price or the valuation of assembly in advance (via batch Precalculation) and to use the result as a reference price. (valuation price "like manual posting"). Alternatively, the valuation method "by planned production costs" can be used.

Depending on the settings conversion to posting quantity the valuation at post calculation price is done as follows:

First partial entry: post-calculation, broken down to the reported quantity

Second partial entry: post-calculation, broken down to the reported quantity less the already booked costs of the first entry

Closing entry: post-calculation of accrued costs less already booked costs of the partial entries.

If there is no final posting, a difference in the WIP account arises! Depending on the valuation, at final posting there could be a different valuation form than in other postings. Accordingly, the valuation of the last posting can leas to other results. In the worst case, the calculated amount is less than 0. In this case, a 0-booking is performed.

Example:

First partial entry: post-calculation planned costs 100 €, one piece posted in for 100 €

Second partial entry: post-calculation planned costs 200 € minus preceding 100 € = 100 €, one piece posted in for 100 €

Closing entry with different valuation: Actual costs 180€ less already booked 200 € = -20€

Problem with cancellations

Calculation work as follows: calculated value less already posted values after a partial delivery. If a partial delivery is canceled, the value "already posted" is not changed. That why no cancellations may be done using this valuation method.

Canceling an assembly: The amount of previously booked values are stored directly in the work order item - split into material costs, manufacturing costs and additional costs. When the assembly is canceled, this amount in the work order item will not be canceled because a recalculation is not possible. As a result, subsequent bookings are incorrectly valued.

Example:

First partial entry: post-calculation planned costs 100 €, one piece posted in for 100 €

Cancellation of one piece

Repeated posting: post-calculation planned costs 100 € less preceding 100€ = 0, 1 piece posted in at 0 €

Second example:

Planned qty 10

Post-calculation: 1000€

First partial posting 5 pcs: 1000 € : 5 = posting price 200€

Continue production, post-calculation 1200 €

Second partial posting 2 pcs: 1200 € - previously posted 1000 € = 200 € : 2 pcs = posting price 100€

Production finished. Post-calculation 1200 €

Last partial posting 3 pcs: 1200 € - previously posted 1000 € = 0 € : 3 pcs = posting price 0 €

Problem with last posting

The last partial posting is defined with the fact that by posting the parts, the manufacturing position is completed.

If you do not specify with the last posting, that the manufacturing position is completed, at valuation method "planned costs at partial delivery" or "partial delivery at material / manufacturing plan costs," is used even for the last posting. A subsequent correction is not possible.

Subsequent BOM correction

If the BOM changes after a receipt, the received part must be re-valued AND the material movement corrected in the production position (previously received material - calculated at target costs).

Right-click on "Finish" in the production position to do this.

see Projection of actual costs, Post-calculation

Type

|

Type

|

Calc.Type

|

Material

|

Routing

|

Surcharge

|

Post calculation (Planned Material costs at Part delivery)

|

N

|

Real

|

Part: Plan

Close: Real

|

Part: Real

Close: Real

|

Real

|

Post calculation (Actual material costs at Partial delivery)

|

T

|

Real

|

Real

|

Real

|

Real

|

Production planned costs

|

V

|

Plan

|

Plan

|

Plan

|

Plan

|

Post calculation (Partial delivery to Material / Production planned costs)

|

P

|

Part: Plan

Close: Real

|

Part: Plan

Close: Real

|

Part: Plan

Close: Real

|

Part: Plan

Close: Real

|

L+M Cost (Plan) + Material Cost (Actual)

|

L

|

Part: Real

|

Real

|

Plan

|

Plan

|

Standard cost method

|

Z

|

-

|

-

|

-

|

-

|

Booking Price

|

S

|

-

|

-

|

-

|

-

|

Plan:

The system create a post calculation for quantity of the current receipt for Plan costs (not Real costs)

Real:

The system create a post calculation for current receipt quantity and all receipt quantities in past. It calculate the Plan- and Real costs for the total of all receipts

Note Lot size costs:

The lot size cost is not related to the quantity. It's always related to this work order position.

|

Plan

Real

Due to the risks the following valuation methods are only available in Expert mode

Field

|

Which costs are used?

|

Post calculation price (planned material costs for partial delivery)

|

Partial posting

accumulated production cost as per post-calculation +

planned material costs as per Precalculation +

surcharges as per post-calculation

less the already posted values.

Final posting: accumulated material and production costs and surcharges as per post-calculation

less the already posted values.

Note:

In this valuation form pre- and post-calculation is used. If at "pricing at valuation" cost at goods sold or costs of sales are indicated, the post-calculation value will be used here. This is calculated from the post-calculation value less material costs, as per Precalculation L-M costs according to post-calculation. This constellation can therefore lead to erroneous results. For this reason, "material and production costs" should be chosen for this configuration.

With this valuation method, at partial posting the option Conversion to posting quantity is considered.

Note:

The use of this valuation method can lead to valuation problems in certain configurations.

|

Post calculation (actual material costs for partial delivery

|

Partial posting and final posting

Cost for material and production and surcharges according to post-calculation.

With this valuation method, at partial posting the option Conversion to posting quantity is considered.

Note:

The use of this valuation method can lead to valuation problems in certain configurations.

|

Post calculation ( partial delivery at material / planned production costs)

|

Partial posting

Costs for material and production costs and surcharges according to Precalculation, See Valuation Planned production costs

Final posting

Cost for material and production and surcharges according to post-calculation,

less the already posted values.

With this valuation method, at partial posting the option Conversion to posting quantity is considered, which may lead to problems when another quantity than the planned quantity is posted.

Note:

The use of this valuation method can lead to valuation problems in certain configurations.

|

L + M costs (Planned) + Material costs (Actual)

|

Partial posting and final posting

Material cost:

- Partial costs to actual costs (possibly with Conversion to quantity to post in) minus the already posted material costs

- Final posting to actual costs minus the already posted material costs

Production costs according

- always to Precalculation less already posted production costs.

Costs of goods sold (Surcharges):

- always according planned costs.

Example Usage of these valuation method Example Usage of these valuation method

|

see Projection of actual costs, Post-calculation

back to Valuation and posting assembly

Help URL: https://help.beascloud.com/beas202102/index.html?bewertungbaugruppe.htm

|

![]() Webinar Product cost determination

Webinar Product cost determination![]() Note: Valuation by post calculation price

Note: Valuation by post calculation price