Only visible for batch related items.

Refers only to backflushing function or the function "issue material".

Here you can specify whether the remaining quantity of a batch can be issued. The starting quantity is specified here.

Example of use:

15 liters are required, 15.02 liters are on stock. Specify: issue remains from 0.1 liters. Then, in the backflushing process remaining stock of 0.02 liters is issued, as this can not be used anymore.

Numbers are given in Inventory UoM, as referring to inventory.

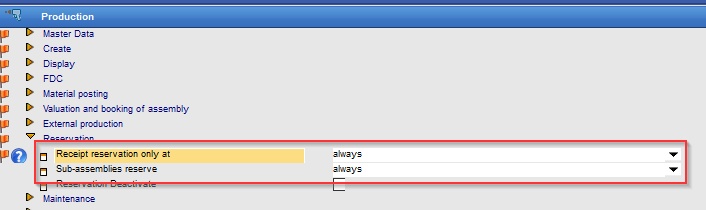

In Configuration wizard > Production > backflushing you can set up, to issue only once at final posting (for example when the completion of a work order is reported) or at every posting.

In work order structure in material row a red dot will be displayed next to the planned quantity, after a value was entered here.

Note:

Backflushing function beas2009-version is not supported.

see Configuration wizard - Material booking - backflushing

If a batch is located on several bins this could lead to problems.

A batch may only be booked to one BOM position.

Example: is is not allowed to post the same item batch on BOM position 10 and 20. Such a constellation could lead to problems.

There may be no further reservation on this batch remaining inventory. If there is a reservation, nothing will be issued.

The remaining quantity is posted to the WIP-account of the work order. A separate posting for the remains is generated. Costs are set in to the work order in the post calculation.

beas9.0-000-002-002

|