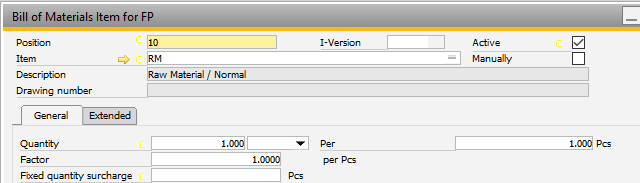

The position number is counted in increments of 10. See Configuration wizard to set up.

The field is alphanumeric with 20 digits.

Note

The order is not related to position number. It is defined in the list of BOMs by Drag&Drop, it reflects the order of entry by default. Position number must be unambiguous.

You find the following fields:

BEAS_STL.POS_TEXT = visible, alphanumeric ID

BEAS_STL.POS_ID = continuous unique ID

BEAS_STL.SORTID = determines sorting

Note on Update:

If you updated from an older version (beas 9.1 PL: 07 and older) , the position text and sorting will be pre-assigned with the previous internal ID (POS_ID).

Advantages

| ✓ | Double Numbering possible (e.g. at maximal BOM) |

| ✓ | Simpler sorting (Drag&Drop) |

| ✓ | Changes of links to routings |

| ✓ | Alphanumeric number assignment (Project manufacturer / Connection to PLM systems) |

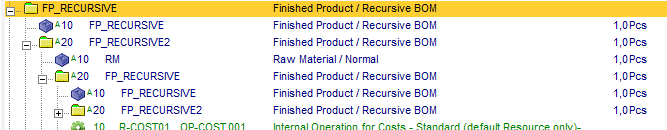

Example: Multiple assignment of same position number

BOM with conditions

Position text

|

Pos Id

|

SortId

|

Variant

|

Description

|

10

|

10

|

1

|

A

|

rod red color

|

10

|

20

|

2

|

B

|

rod bue color

|

10

|

30

|

3

|

C

|

rod yellow color

|

20

|

40

|

4

|

|

screw 6 x 40

|

30

|

50

|

5

|

|

screw 3 x 50

|

The position 10 was assigned 3x times, respectively for a variant in this example

Only one of the 3 positions will be used in dependence of the variant, so that always a correct BOM will be created with the position numbers 10-20-30 without re-numbering.

Example: Alphanumeric Position number

Alphanumeric position numbers will be assigned often at complex drawings. This is now possible.

Important: A sorting by the alphanumeric number position is not wanted here generally, because the alphanumeric positions will also be used as position ID on a technical drawing.

Position text

|

SortId

|

Description

|

Z1

|

1

|

Module 400o-200

|

A-5020

|

2

|

Module 300a-400

|

A-5020/1

|

3

|

Screw 3x20

|

A-5020/2

|

4

|

Screw 4x25

|

AS_APL / BEAS_FTAPL.POS_TEXT

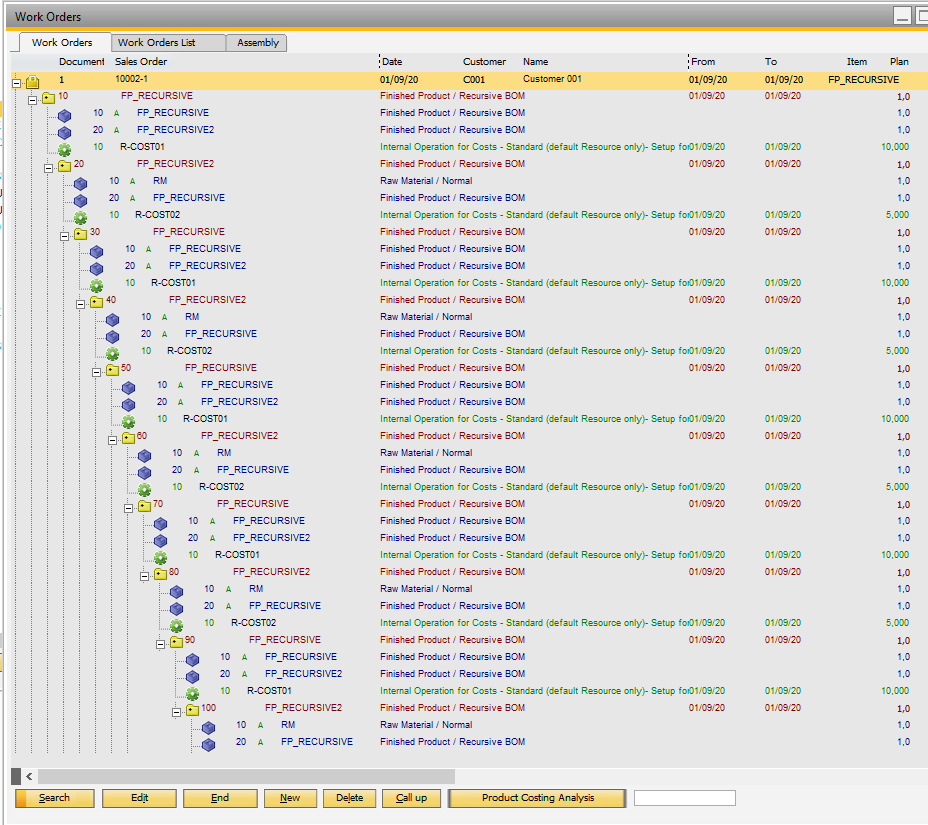

Renumber at creating work order

The BOM can be renumbered automatically if a work order is created, but the parameter for this can be deactivated in the Configuration wizard.

Note: For Phantom items BoM positions are always renumbered - even when the parameter is off.

Left to the position field you can open the script window by clicking the formula icon ("display formula fields") Call-up is also possible via right-click - script

Note: This function is only available if the Variant generator is activated in the Configuration wizard.

The following variables are available:

Variable

|

Description

|

e_belnr_id, e_belpos_id

|

Work order, Work order position

|

e_itemcode

|

The Assembly from work order position

|

e_quantity

|

Quantity in regional format

|

e_source

|

"routing"

|

e_info1

|

Info for current routing position

|

e_rohitemcode

|

The Material from Bom

|

See Variant generator - Script

|

Sorting function Sorting function

|