Attendance

|

Imports attendance data.

The following details are required:

Personnel numbers and start dates are matched during the update.

Attention:

It is not possible to link order times with attendance times if the attendance data is imported, because the order times are calculated at the time of the order time receipt and the attendance report is usually not imported at that point.

|

|

Personnel

|

Import Personnel Data for Beas Personnel data

Synchronize Human Resources -> Employee Master Data:

- If not existing, the system creates a new entry automatically

- if existing, the system update follow fields: First Name, Last Name, Middle Name, Date of Birth, Start Date, Termination Date

|

|

Absence

|

Imports absence areas, like holiday, sick leave, etc.

The primary keys are "Personnel Id" and "from date". It is also possible to update this data.

The following details are required:

|

|

|

Order times

|

Imports work order times.

This data can only be imported and it is not possible to change existing order time receipts.

The following details are required:

| • | Work order document number |

Dates have to be indicated in yyyy/mm/dd format and time in hh:mm format. Example: 2016/05/17 09:00

Backflushing

The Disable backflushing filed is enabled by default. The backflushing process can be deactivated here. To activate, set the filed to Y.

Only material and assemblies can be posted, if the data could be identified automatically.

Important:

The time is not set, it must be indicated. All rules stored in the Configuration Wizard are applied.

|

|

|

A work order has the following objects:

| • | Work order bill of materials and routing position |

Example:

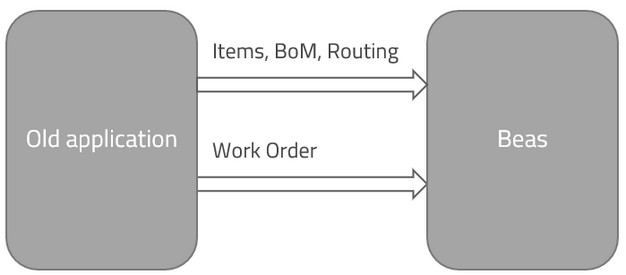

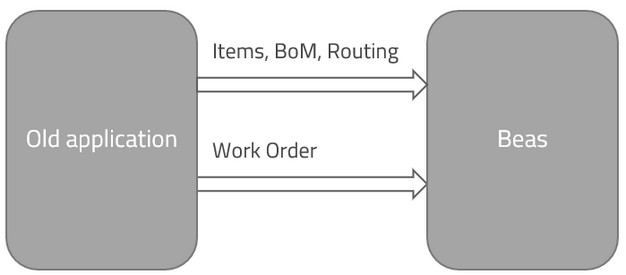

The old system contains all item, bill of materials and routing information. This data can be imported with the integration hub. After this is complete, work orders can be imported.

Only the top level assembly can be defined. Beas reads bill of materials and routing information from imported master data.

It is not possible to import routing or bill of materials for every work order separately.

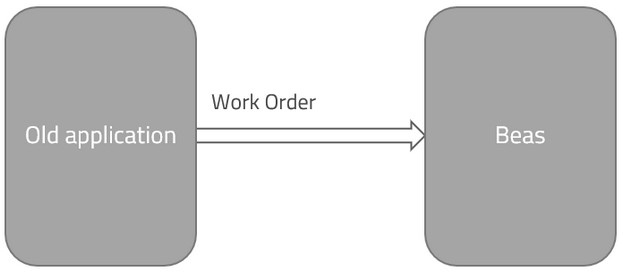

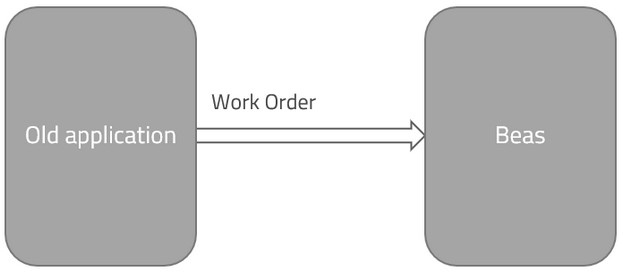

A third-party application can define the work orders in Beas. You can use this option if you have an external planning tool for production in stock.

|

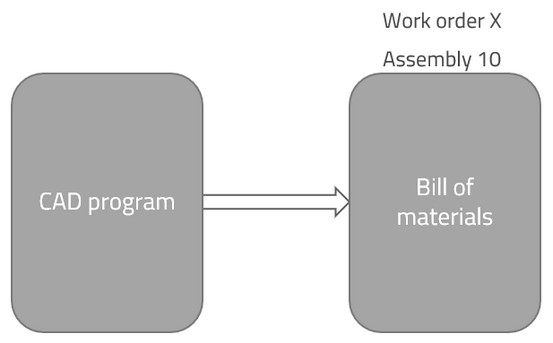

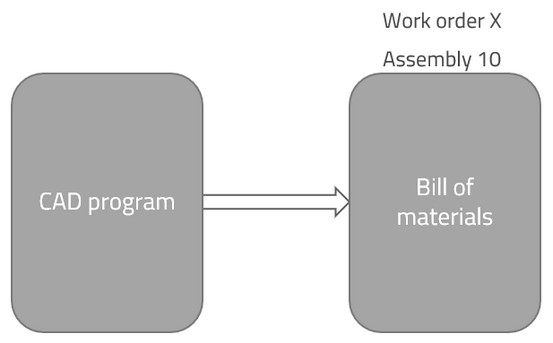

Example: A machine needs to be produced and while producing the technical planning continues. You can import and synchronize the bill of materials in the work order directly from the CAD program.

|

Area

|

Insert

|

Update

|

Work order header (BEAS_FTHAUPT)

Use this if you want to update the header information or if you want to create new work orders and you need only the item code and quantity for the work order position.

|

Inserts all header information.

Inserts first work order position with item code and quantity.

Beas explodes the bill of materials, routing position and all order-related sub-assemblies.

Note:

Creating reference to other documents or changing any properties in the work order line is not possible.

You can change the work order type, but it is not possible to change the work order type related flags; Beas ignores these changes.

You cannot define the document number (BEAS_FTHAUPT.BELNR_ID), only the order number (BEAS_FTHAUPT.AUFTRAG).

|

Most properties are changeable, but you cannot change the created work order positions.

Beas will ignore the item code and quantity property.

|

Work order position (BEAS_FTPOS)

Use this to import work order positions with extended position information.

The assembly can be defined, but Beas always uses the BOM and routing information from item master data.

|

Add position to existing work orders.

Beas explodes the bill of materials, routing position and all order-related sub-assemblies.

If you do not define a work order number, Beas creates a new work order (BELNR_ID=0).

It is not possible to define additional information for work order header if the system creates a new work order.

Defines linked information.

|

It is not possible to update existing positions.

|

Bill of materials (BEAS_FTSTL)

Use this to synchronize the BOM with external programs.

you can add and change bill of materials position of existing work order positions.

|

The work order document number, work order position and bill of materials position are mandatory.

When trying to insert an exiting BOM position, Beas updates the position.

Beas does not explode order related assemblies. Multilevel work orders cannot be created.

|

All properties of an existing bill of materials position can be updated.

Beas does not change existing sub-position.

You can delete a BOM if you set the quantity to 0, but only if no related transaction or reservation exists.

|

Routing position

|

Not possible.

|

Not possible.

|

The following fields are mandatory:

| • | Document number, work order position number, bill of materials position number |

Entries can only be changed if changes are allowed and the work order position is not closed.

Position numbers:

| • | The internal position number. If this is a new number or if it is 0, Beas creates a new position. |

| • | If you do not set the position text, Beas sets the position number in position text. |

| • | The internal position number does not define the sorting. You must define this separately. See Sorting rules. |

Position text:

| • | If this is not set manually, Beas inserts the defined or generated internal position ID. |

| • | It can be defined and changed every time. |

ItemCode:

Item code is mandatory and the item must exist.

The integration hub does not check additional rules.

If you change the item and the related position, reservation or transactions exist, Beas does not change anything.

Note: If you insert an order-related item, Beas does not create an order-related sub-position.

ItemVersion:

The system check, if the Item Version is existing and not locked

But it's allowed to use it, if not released.

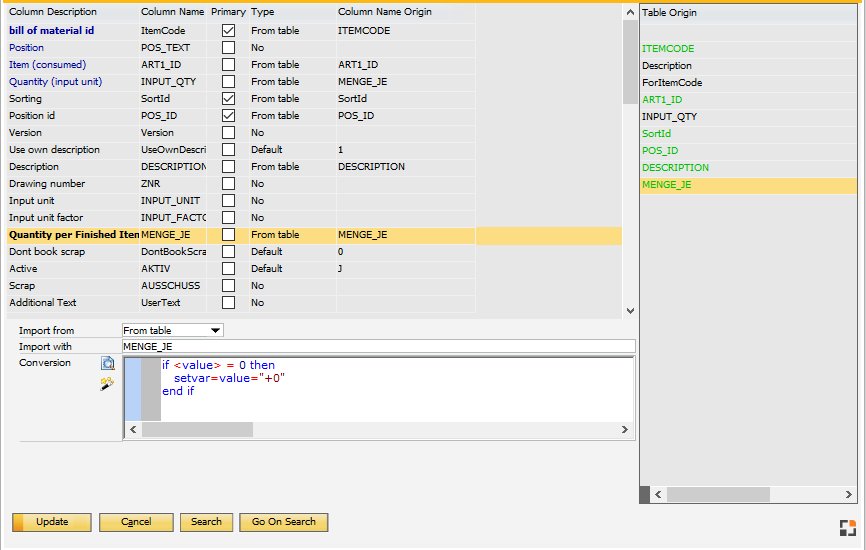

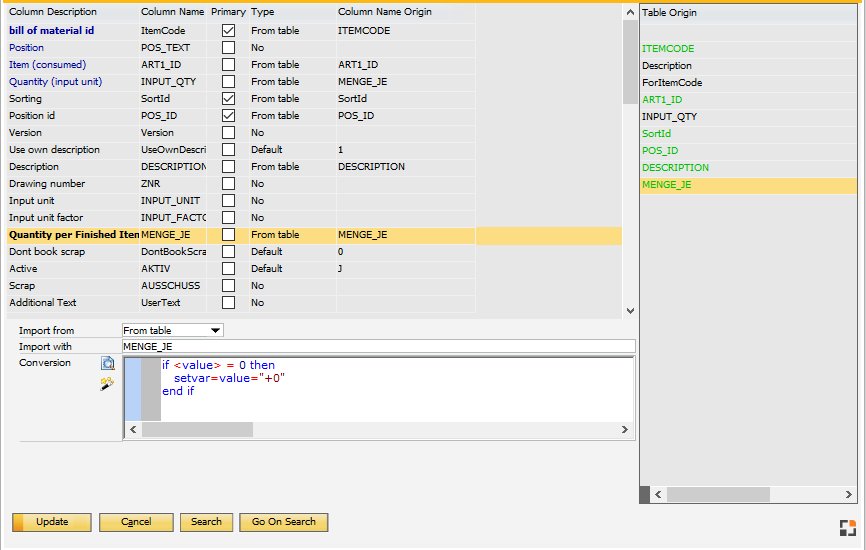

Quantity:

Rules for quantity in the BOM import:

| • | A value > 0 inserts a positive amount. |

| • | A value < 0 inserts a negative amount. |

| • | A value of +0 adds a position with 0 amount. |

If you only have 0 quantity in the importfile, you can convert the value

|

Delete a bill of materials position:

It is possible to delete an existing Bill of materials position. Beas requires the following fields: BELNR_ID,BELPOS_ID and POS_ID and Quantity=0.

| • | If any transaction exists on this position, the position cannot be deleted. |

| • | If a reservation exists, Beas deletes the reservation. |

| • | If the position is an order-related assembly, Beas deletes all related sub-positions. |

| • | If a deletion of a sub-position is not possible, Beas closes all related sub-positions. |

Sorting (SortId):

Defines the sorting for the bill of materials positions. You can define a positive number or special sorting rules.

Sort Id

|

Description

|

-1

|

Order by internal position number. The system searches by position, and chooses a number that is lower than the current position and higher than the lowest existing position. It receives this sortid, increments it with 1 and defines it as a sortid from the current position.

Example:

Pos 10 – Sort 10

Pos 20 – Sort 20

You insert Pos 15

Pos 10 – Sort 10

Pos 15 – Sort 11

Pos 20 – Sort 20

This is a fast variant, because Beas must only insert Pos 15, but in other situations this can generate a problem.

Example:

Pos 10 – Sort 1

Pos 20 – Sort 2

You insert Pos 15

Result in MSSQL:

Pos 10 – Sort 1

Pos 15 – Sort 2

Pos 20 – Sort 2

Result in HANA:

Pos 10 – Sort 1

Pos 20 – Sort 2

Pos 15 – Sort 2

In this case Pos 20 and Pos 15 have the same Sort id and it is not clear which position is the first position.

|

-2

|

Order by internal position number.

In this case Beas sorts the complete bill of materials position by internal position number

Beas must save every change from every bill of materials position. In case a large number of positions must be inserted, this concept produces a lot of change requests. Do not use this for mass import.

Example:

Pos 10 - Sort 10

Pos 20 - Sort 20

Pos 30 - Sort 30

You insert Pos 15

Pos 10 – Sort 10

Pos 15 – Sort 20 <- insert

Pos 20 – Sort 30 <- update

Pos 30 – Sort 40 <- update

|

-3

|

Order by position text (alphanumeric).

Example

Pos Text A10 Sort 10

Pos Text A20 Sort 20

Pos Text A50 Sort 30

You insert position with Pos Text = A30

Pos Text A10 Sort 10

Pos Text A20 Sort 20

Pos Text A30 Sort 20 <- insert

Pos Text A50 Sort 30 <- update

Attention: You can encounter the following issue when working with numbers:

Example

Pos Text 10 Sort 10

Pos Text 20 Sort 20

Pos Text 100 Sort 30

Insert Position Pos Text = 50, and the result (alphanumeric sorting) is the following:

Pos Text 10 Sort 10

Pos Text 100 Sort 20 <- update

Pos Text 20 Sort 30 <- update

Pos Text 50 Sort 40 <- insert

|

-4

|

Order by position text (converted to number)

Example

Pos Text 10 Sort 10

Pos Text 20 Sort 20

Pos Text 100 Sort 30

You insert position with Pos Text = 50

Pos Text 10 Sort 10

Pos Text 20 Sort 20

Pos Text 50 Sort 30 <- insert

Pos Text 100 Sort 40 <- update

If you insert a position with alphanumeric position text, Beas sets this to first position.

Example: insert position with text A001

Pos Text A001 Sort 10 <- insert

Pos Text 10 Sort 20 <- update

Pos Text 20 Sort 30 <- update

Pos Text 100 Sort 40 <- update

|

|

|

|

Item

|

Import and match items.

When a new item is imported, the "default item" from the Configuration Wizard is used as a reference. As an alternative, it can be set in the "e_sourceitem" variable (to define in conversion script from field "Itemcode") and an alternative default item can be used.

item import procedure:

| 1. | Define the default item. Fill all fields (unit of measure, planning method, procurement method etc.). |

| 2. | Set the default item in the Configuration Wizard |

| 3. | Define and perform import |

Note:

Material group, unit of measure and item group can be created automatically, if Extended / Create groups and units was enabled in the import . If the data is incomplete, the data set is not created.

The following fields have extended settings:

All unit of measure fields

|

In case a unit of measure that does not yet exist in the UoM table, is imported, it is automatically created.

|

Material group (u_BEAS_GRUPPE)

|

Material group is automatically created, if it does not exist.

|

Item group

|

When, instead of the item group ID, the item group description is indicated, the internal item group ID is determined and used automatically in the description.

When the item group is not found, it is automatically created.

|

Procurement method

|

If enabled, the scheduling ID is set to storage-related assembly, otherwise to it is set to Purchase item.

|

I-Version

|

If a version number is entered, an item version is created immediately. This is done independently of the Create groups and units settings.

|

|

|

Bill of materials header

|

|

Bill of materials position

|

Bill of materials is imported.

A bill of materials is always seen as a whole and can only be imported completely. In case of an update, the BOM is deleted first and re-inserted. It is not possible to update single positions, but synchronization can be done on position level.

An item needs to be defined which is used if the imported position has no valid item number. This is done in the Configuration Wizard.

The correct order for an import is:

| • | Bill of materials head data |

A bill of materials can also be imported directly. Positions numbers are assigned automatically if they are not set manually.

If the material number is not defined, the default item is inserted, and the bill of materials is set to manually.

If the stored material number is unknown, the default item is inserted, bill of materials position is set to manually and the transferred item number is inserted into the information field.

See Edit bill of materials.

|

|

Bill of materials alternative material

|

Import alternative items related to a BOM. See Alternative material.

|

Routing header

|

Import routing master data.

|

Routing position

|

Import the routing.

The standard operation type needs to be defined. Resources must be created. You can work with operation sequence catalog numbers. In this case, all default values are accepted.

A routing can only be imported or replaced completely. Single routing positions cannot be replaced.

Important:

When working with parallel resources, the input of the internal position number is necessary for linking.

|

|

Item parameter

|

Import the item parameter.

|

QC cross reference

|

Import item related QC orders.

|

|

Resource

|

Import master data resource.

|

Routing catalog

|

Import routing catalog or templates.

|

Warehouse areas

|

Import the bin warehouse areas.

|

Bin location

|

Import the bin location definitions.

|

Business partner

|

Import of the business partner master data, contact person billing address and delivery address.

|

Tools

|

Import of tool master data and tool BOM.

|

|

QC Header

|

Import quality control header.

|

QC Position

|

Data import is also possible if no header data is created. The header data is created automatically.

During an update, positions can only be added or changed, but not deleted.

|

|

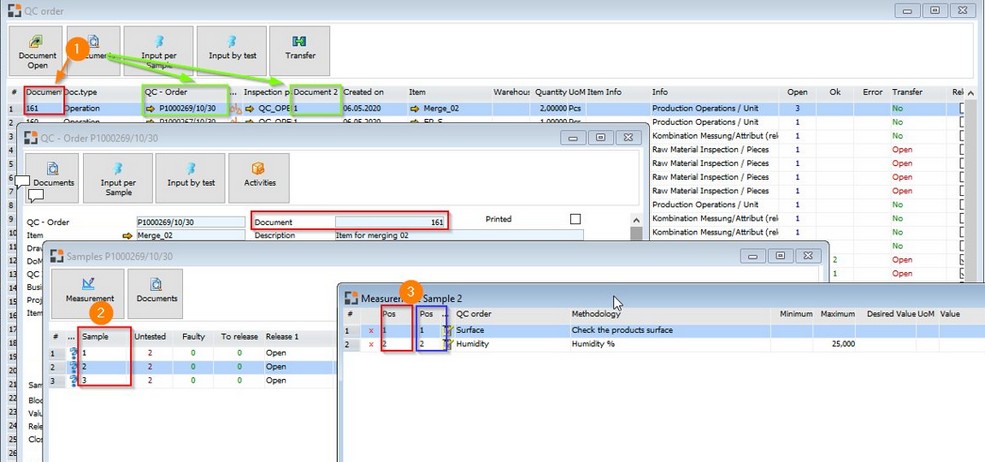

QC Order results

|

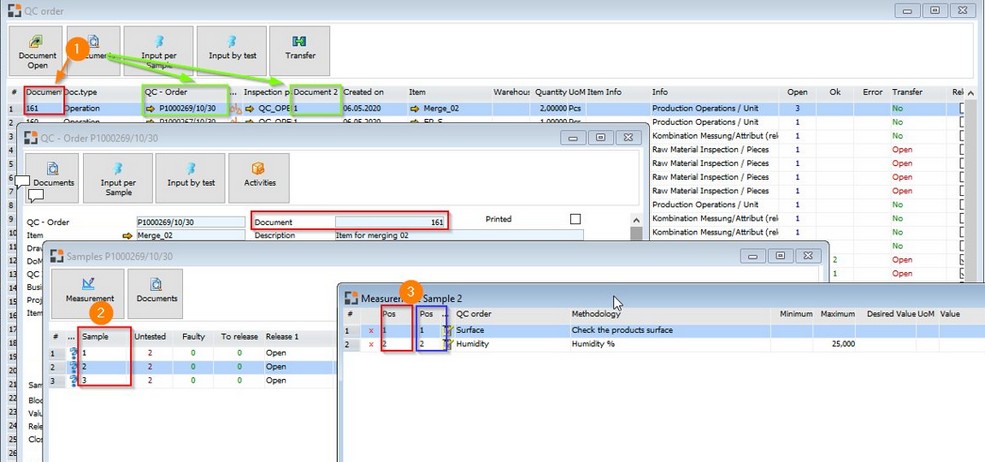

The following information is mandatory (see image):

- Document number (red) or, alternatively, QC order + Document 2 (green)

- Position: Pos_ID (red) or Pos_text (blue)

|

|

|

Material transactions are defined in a definition file: "Transaction plan lines".

Different transaction types like receipt and issue, goods receipt etc. can be executed here.

The transaction type is indicated in the "Transaction Type" field.

The following transaction are supported:

Transaction Typ

|

Description

|

WOIM

|

Production – Material issue

|

WORM

|

Production – Material / Assembly receipt (beas 9.3 PL 2 HF 2)

|

MANIN

|

Manual posting or stock re-taking

|

Link example for work order issue document

All this fields in this table are mandatory

Field

|

Value

|

Transaction Type

|

WOIM

|

Link Document Type

|

"WO"

|

Link Document

|

BEAS_FTSTL.BELNR_ID

|

Link Line 1

|

BEAS_FTSTL.BELPOS_ID

|

Link Line 2

|

BEAS_FTSTL.POS_ID

|

ItemCode

|

BEAS_FTSTL.ART1_ID

|

Quantity

|

the Issue Quantity in Inventory UoM

|

WareHouse

|

The WareHouse from the Item OWHS.WhsCode

|

Bincode

|

Bincode, if warehouse is a bin managed warehouse

Supported: SAP, WMS and beas bin management

If this is a WMS or beas bin managed warehouse, the bincode is mandatory

|

BatchNumber

|

Normal Item: Empty

Batch Administration: OBTN.DistNumber

Serial Administration: OSRN.DistNumber

if this is a work order receipt or purchase receipt and batchnumber generation is activated, then it's not mandatory to fill it

|

Important:

The data must be checked for correctness before the import. There is no further check in the import process-

The values must be checked in the Import Preview function or all necessary checks must be defined in the Source – Target – Link.

|

Help URL: https://help.beascloud.com/beas202102/index.html?definitiondatenziel.htm

|