|

In this window the required material is issued for a manufacturing position.

Note: For backflushing in Configuration wizard the option Production - Material posting - Backflushing - issue quantity changeable needs to be set to "Yes".

PATH: Production > Work Orders > right-click an issue in the WO structure / right-click an item > "Material issue".

Window structure

- Work order structure > issue material. Quantity refers to the full remaining planned quantity

- issue material via routing-time receipt. Quantity refers to time receipt screen. The material belonging to the operation is displayed. In case of the last operation to be reported, the assembly may be posted in afterwards.

- External operation > Material issue: to issue the planned material from an external warehouse (see allocations). Quantity refers to external operation-goods receipt

|

The active field is always the entry field in the lowest line. This can be used for registration via scanner. There are two settings:

Production > Material posting > Backflushing > Material posting with scanner.

Active:

A matching batch or serial number is searched. If an entry is found, it will be used and the required quantity is accepted. If no entry is found, an error message is issued: no entry found.

If the entry is blocked, (batch status, blocked bin location) the entry is not accepted, a message is issued.

Inactive:

Beas searches for the following entries: Batch number: field is selected, the cursor is set to quantity field.

Serial number: quantity is accepted immediately.

Item: entry selected, cursor is set to quantity field.

If no matching entry was found and the entry is numeric, the current entry is accepted including the quantity.

Error messages are issued in no case.

See

Configuration wizard – Material posting with scanner

Reservation

Material issue

Allocation

External operation Allocation

External operation issue

beas9.0-000-003-006, beas9.0-000-002-024, fert_scanbatchqty (J)

|

Negative BOM items are displayed in the work order structure with the same icon and positive values. If selecting one, in the window left below not the warehouses are displayed but the entry values can be entered manually. Warehouse, bin location, batch / serial number and quantity can be entered. After entering the quantity, data is saved. Here, the same concepts apply for batch determination and pricing as used in Collective receipt (beas9.0-000-003-014).

|

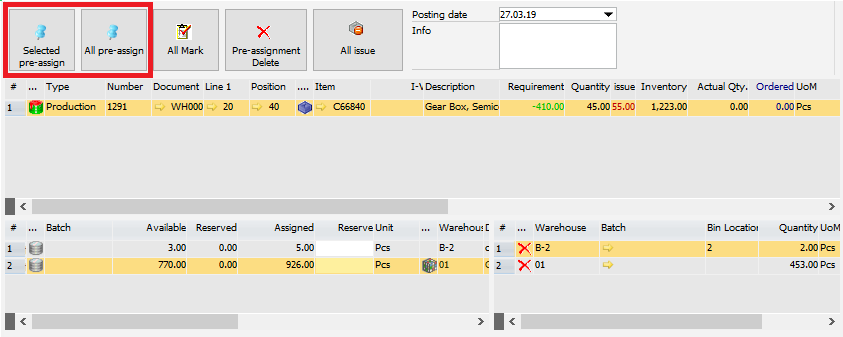

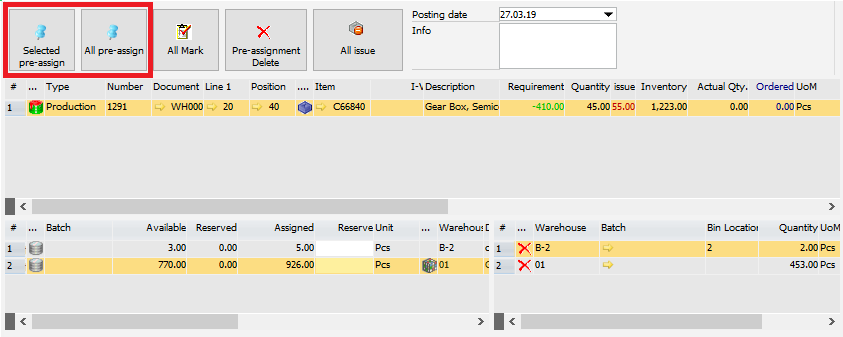

Functions in upper ribbon

|

|

|

Pre-allocate marked entries

|

All priorities are considered:

1. Reserved goods for this order line (not in reservation window).

2. Allocation warehouse (see Allocation window).

3. Default warehouse as per BOM or standard warehouse of the item or

Default warehouse for backflushing as per Configuration wizard - backflushing - issue from allocation warehouse.

Within this sorting, batches and serial numbers are sorted by withdrawal rule according to configuration wizard.

See Backflushing - Automatic batch issue.

Note:

If a warehouse is stored in Configuration wizard - backflushing - issue from allocation warehouse, only this warehouse will be considered at automatic backflushing.

If the option "book only reservation" in the BOM position is active, only reserved entries are chosen, even if these are not sufficient.

See Edit Bill of Material - Book only reservations.

Items which are not batch or serial number related, will be pre-allocated only, if in Item master the issue method was set to "automatic" See Item master - Issue method.

Note: Allocation warehouse is set up per work station. see Allocation window.

negative BOM items

Negative BOM items are also pre-allocated, if

a) Batches/Serial numbers are defined automatically

b) The warehouse is not a bin location warehouse

Batch and serial numbers

Within this, batches and serial numbers are sorted by withdrawal rules according to the Configuration wizard.

See Configuration wizard – Backflushing

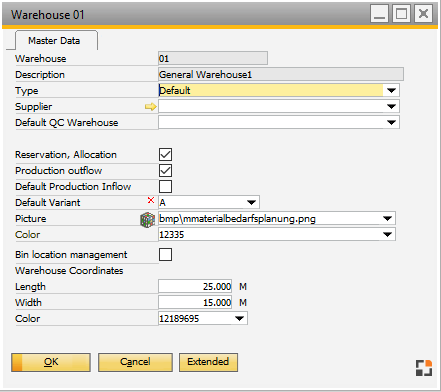

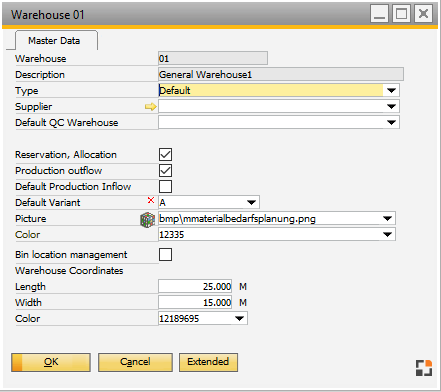

Warehouse

Only warehouses allowed to be used for the relevant process are considered (Reservation, issue etc.)

See extended warehouse settings

Available at General settings > Warehouse > Warehouse master data > Extended

Window bin_whs_edit.psr

Attention

SAP Bin Management not supported.

|

Window bin_whs_edit.psr

Extended rules can be stored in the function workordermanagement.setres_supply()

For further information see Extended rules.

PATH: Production > Work orders structure > right-click an entry > "Reservation".

Window resevation_set_master.psr

These extended rules can be stored in the function "workordermanagement.src". (In project folder)

Depending on the window a specific function is called, for example for reservations setres_reservation()

For more information see

UserEvents

UserEvents for PreAssign

|

Note

If working with Report work order times > Scrap quantity, the planned scrap and offcut may not be taken into account.

See

Configuration wizard – backflushing

Requirement – Reservation screen requirement – column requirement

|

|

Pre-allocate all

|

All entries are marked and then pre-allocated

|

Delete pre-allocations

|

All pre-allocations are deleted

|

All issue

|

All marked material is charged off.

|

Fields right to the buttons at the top

Only some fields explained in the table below are displayed, depending on the work flow.

|

|

|

Posting date

|

Select the posting date.

|

Info

|

Text field for comment.

|

Serial numbers

|

This list is only displayed if

a) the finished part is serial number related.

b) the selected material is serial number or batch related.

c) serial number reservation was set to automatic and serial numbers are generated automatically for the assembly or if serial number reservation was set to manually.

Serial numbers to be posted in are displayed and new serial numbers to be posted in can be added.

If an item is selected, it is assigned to the currently marked number.

The Function "issue material" does not post immediately. Manually added serial numbers are reserved first and assigned to the work order - even if serial number reservation was disabled. Existing reservations are always displayed. See Configuration wizard - Assembly - Serial numbers

The function "backflushing issue" for example via "last operation" displays only the serial numbers to post in. Additional serial numbers can be entered manually. To post in, select serial numbers by clicking the check mark. The number of selected numbers needs previously selected number. Otherwise a message is issued:(issuewoserlnk)"Please select a serial number item and in the upper window the serial number to be posted in. Planned quantity xxx, selected yyy"

At the assignment of serial numbers to serial numbers the material serial numbers may not be selected automatically. A manual selection is required. That why it is recommended to set backflushing to of serial numbers to "manually" See Configuration wizard – Material – Backflushing – Serial numbers, Serial number reservation, Serial number tracing.

beas9.0-000-003-000

|

|

Right-click menu

|

|

|

Reservation list

|

Open the reservation list.

|

Reservation delete

|

Delete existing reservations.

|

Filter: all

|

Lines which have been posted are also displayed.

|

Filter: only requirement

|

Standard view. Only lines which have not been posted are displayed.

|

New series

|

This button is active only if assembly and material position are serial number related. With "New series" a new serial number to be posted in later can be added and assigned to the serial number to be issued.

See Serial number.

beas9.0-000-001-000

|

| • | WMS, SAP and Beas Min management system supported. |

| • | Beas RFID and WMS LUID supported. |

| • | Not possible to create issue from same batch from different Bin locations or same Bin location but different RFID/LUID. |

|

back to work order general

Help URL: https://help.beascloud.com/beas202102/index.html?materialabbuchung.htm

|