Planned receipt quantity.

Can be (example)

- Work order positions

- Negative Work order Bill of Material positions

If it is an order-related sub position from a work order, it only appears as neutral quantity (gray).

If the quantity is higher than the quantity of the related Bill of materials position, only the quantity higher than the Bill of materials quantity is shown.

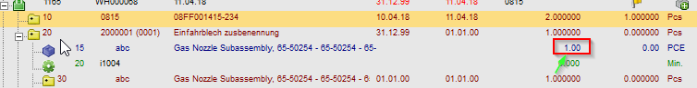

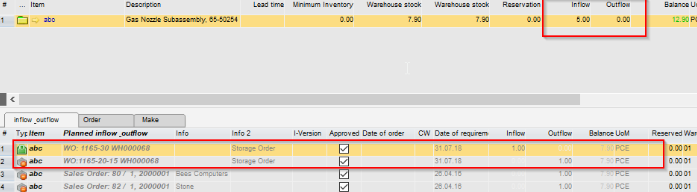

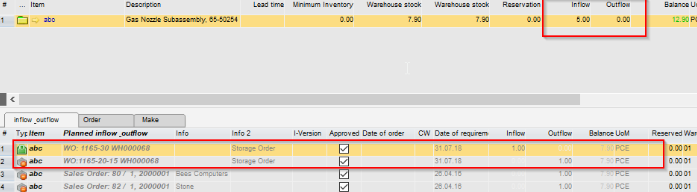

Example: Special case for inflow or outflow work order subassemblies:

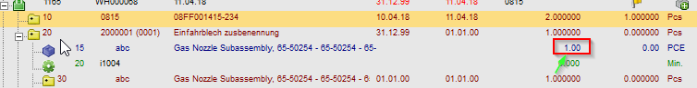

work order with order related subassembly (bom position 10, item abc, covered by work order position 30, item abc)

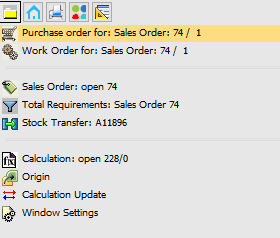

PATH: MRP > MRP Wizard > Select a scenario and click the Order recommendation button

Bill of materials: 1 Pcs

Subassembly order related: 1 Pcs

Balance is 0, inflow and outflow neutral.

This is not visible in inflow or outflow, and in the requirement list it is gray.

PATH: MRP > MRP Wizard > Select a scenario and click the Order recommendation button

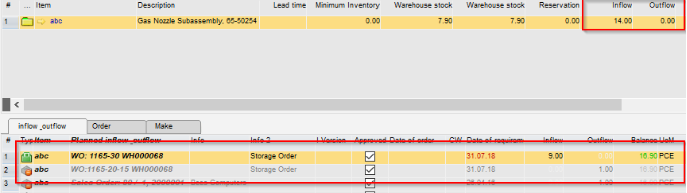

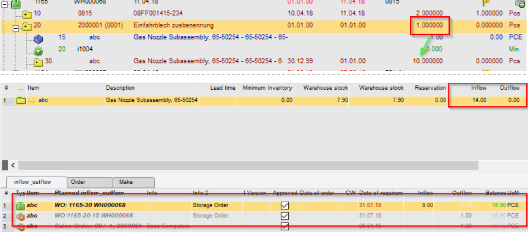

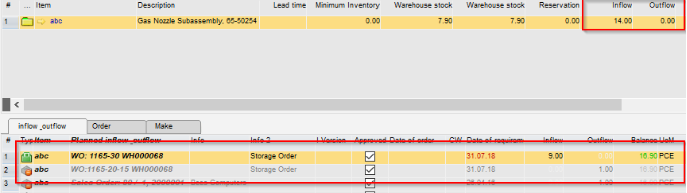

However, if you change the quantity from order-related subassembly, it changes. The quantity displayed is not for the main assembly but for the stock.

PATH: MRP > MRP Wizard > Select a scenario and click the Order recommendation button

|