Field |

Description |

Delivery date customer order |

Delivery date stored in the customer order, prognosis, or another requirement originator. |

Average delivery time |

Average delivery time in work days, defined in the Configuration Wizard. |

Lead time according to item master |

Lead time in working days according to the item master, given lead time for planning. |

Calculated lead time |

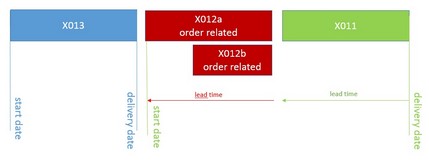

For an assembly (storage-related production): Using a backward scheduling simulation (routing of the assembly) the latest possible start date is calculated. Lot size is the requirement quantity. Order multiples are not taken into account here.

For order related production: Using a backward scheduling simulation (routing of the assembly) the latest possible start date is calculated for the complete order related item structure. This corresponds to the start date of the sub-assembly which must be produced first. Lot size is the requirement quantity.

Important: The order multiples, lot size, existing time reservations on resources are not taken into account during calculation.

If calculation of the lead time was disabled, the item lead time is used as reference. The lead time is the sum of a single lead times of the order related sub-assemblies.

Example 1: Lot size and setup time. Assembly A with operation sequence A1, 10 days setup time, lot size is 10. Company calendar: Every day is a working day.

Customer order, delivery date 30.12. Pos 1 100 pieces: Calculated: 10 days, start 20.12. Pos 2 100 pieces: Calculated: 10 days, start 20.12. Pos 3 200 pieces: Calculated: 10 days, start 20.12.

Example 2: Lot size and time for processing. Assembly A with operation sequence A1, time for processing 1 hr/piece, lot size is 10. Company calendar: Every day is a working day. Resource has 1x10 hrs/day. 100 pieces = 10 days

Customer order, delivery date 30.12. Pos 1 100 pieces: Calculated: 10 days, start 20.12. Pos 2 100 pieces: Calculated: 10 days, start 20.12. Pos 3 200 pieces: Calculated: 20 days, start 10.12

Apparently, there is a problem, there is only one single resource, capacity limits and time reservations are not taken into consideration. This problem can only be avoided by the production orders being created as planned orders. Using APS, planned orders can be correctly scheduled and necessary resource times can be reserved. |

Requirement date according to the forecast |

The planned requirement date that is defined in the forecast. In a monthly forecast, it is the beginning of a month, in weekly forecasts, the Monday of the respective week. In case of an assembly, the required date of the sub-assembly is earlier. |

Pre call time for prognoses |

In the Configuration Wizard MRP > Calculation > Forecast > Pre call time for prognoses in calendar days. |

Determining the date, depending on pegging

Field |

Description |

||||||

Customer order purchase part |

Delivery date according to the customer order, average delivery time. Lead time according to the item master, period needed for replacement. |

||||||

Customer order anonymous and order related production |

Delivery date according to the customer order, average delivery time. Lead time according to the item master, period needed for replacement. |

||||||

Forecast purchase part |

Requirement date pre call time for prognoses, lead time according to the item master, period needed for replacement. |

||||||

If the BOM is assigned to a routing position, its Processing time – Start time is as follows:

From the date computed this way, the first working day is determined according to factory calendar. Then the Item – lead time is subtracted in calendar days, then the lead time – safety days as per configuration wizard is subtracted in work days. If dealing with a purchase part, the Goods receipt – Idle time is also subtracted.

If the resulting date is in the past, the order recommendation date is the next work day starting from the current day.

|