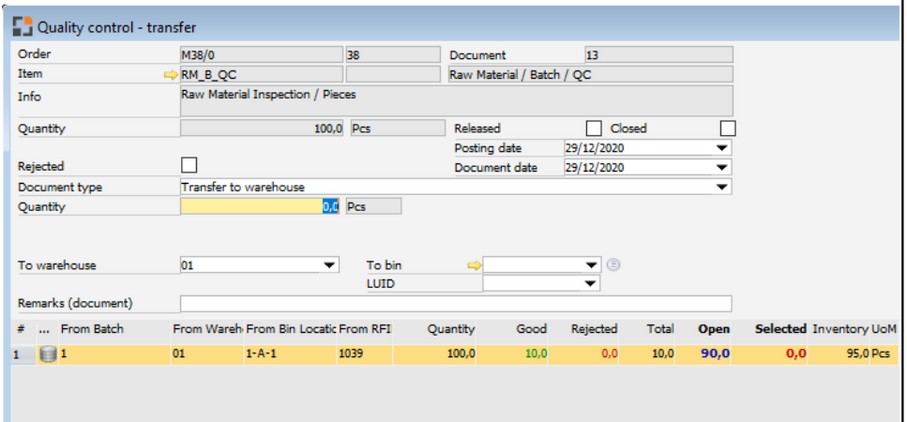

In this window goods to be checked can be transferred from the QC warehouse to the release warehouse.

Window qs_transfer_header.psr

Note: The window can only be opened if the goods have been posted to a goods receipt warehouse. Alternatively, a QC inspection plan can be set up making transfer possible from any warehouse.

See QC inspection plan – Release, Warehouse master data – Type of warehouse

See our QC Transfer WebApp dedicated to this function.

![]() QC by Sample - QC by Test - QC Transfer (WebApps 2.1) demonstration

QC by Sample - QC by Test - QC Transfer (WebApps 2.1) demonstration

Authorization for QC-Order is required. See concept Work with QC-warehouse.

The booking process

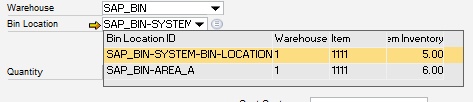

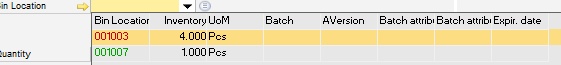

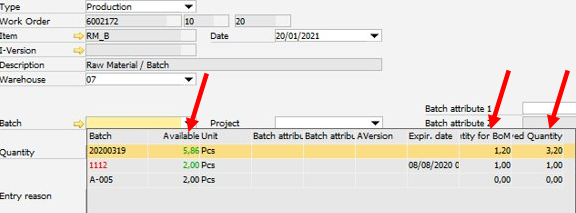

A booking is always performed from the warehouse/bin location that has been posted for the quality control order.

A pure bin location transfer is performed in case of a new bin location.

A transfer transaction is performed if the target warehouse is another warehouse. A manual posting and issue is performed in case of another item or batch number.

After the complete quantity was posted, the QC-order is marked as posted. Various rules can be applied to this process.

Booking details are displayed for the entry currently selected in the lower list. List of items to be posted supports windows settings and templates.

|

![]() Information Columns/fields in lower screen section

Information Columns/fields in lower screen section

|

|

If you create a transfer document, the Macro named "default" (if existing) is executed automatically. For further information see customized extensions. |

The following extensions are executed: beas 9.3 PL 3

windowevent pretransfer (for all document types)

For every created document, the system will post the following events: Information of dw_2 is not deleted It is not allowed or possible to cancel or close the running process: windowevent transfercreated windowevent issuecreated windowevent receiptcreated windowevent poreturncreated

windowevent posttransfer (for all document types)

If "pretransfer" is ended by "return failure", the process is canceled. For posttransfer the variable "e_docentrys" is available, in which the created documents are available comma-separated (transfers, issues and receipts). The event is called up before the print.

Data connection In the created transfer document the following information is stored: WTR1.U_beas_basetype = QC (good quantity), QB (bad quantity) WTR1.U_beas_basedocentry = BaseDocument.Docentry WTR1.U_beas_baseline = BaseDocument.Linenum

The BaseDocument is goods receipt, credit note, receipt etc. beas_plandocument_line.docentry=<docentry> = BEAS_QSFTHAUPT.DocEntry beas_plandocument_line.doctype='QC' |

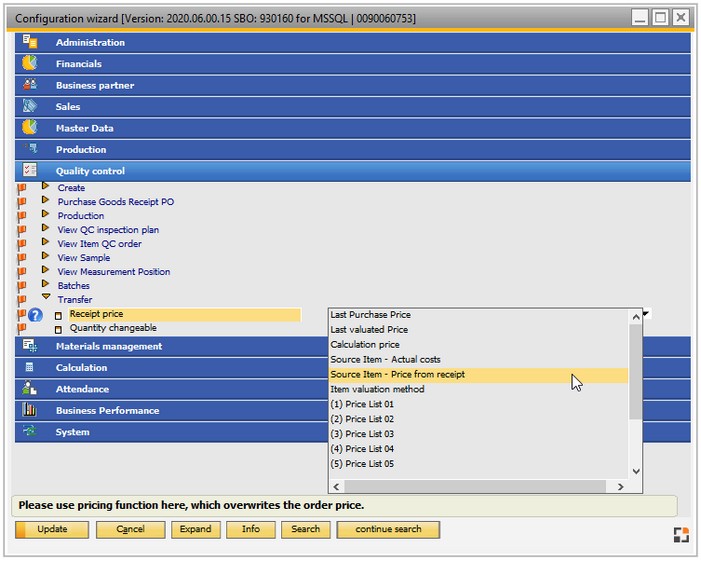

Window configuration: