![]()

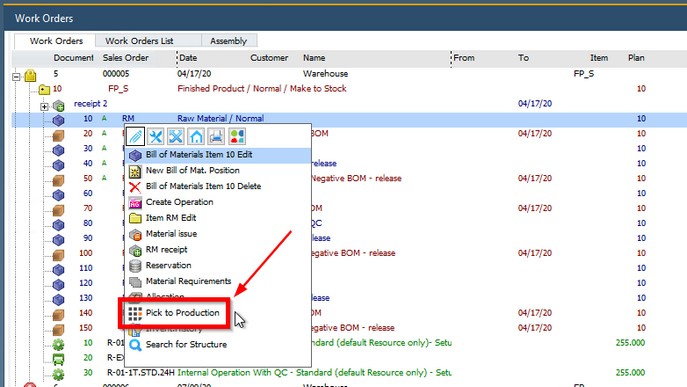

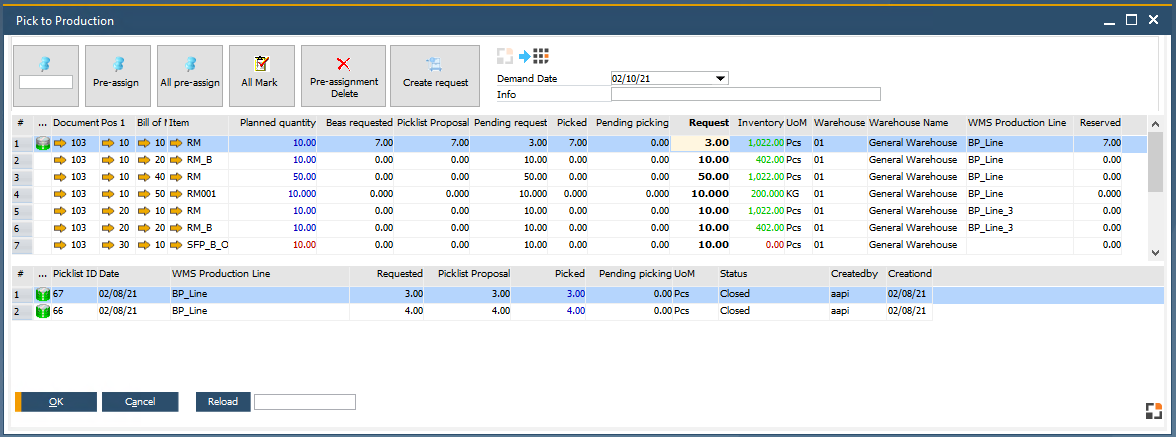

In this window you can create a request for picking to production.

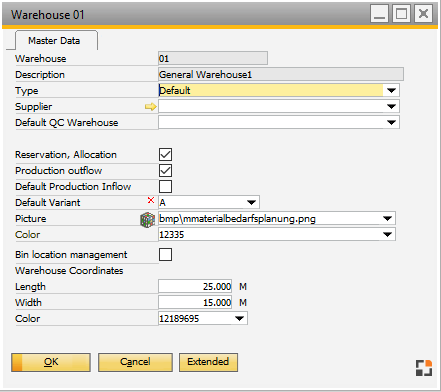

See WMS settings

See WMS Picklist for production workflow.

PATH: Production > Work orders > right-click a WO or BoM position

Note: You can also access the function by multiple selection of WO Headers/positions and BoM positions.

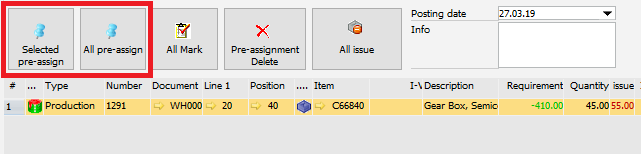

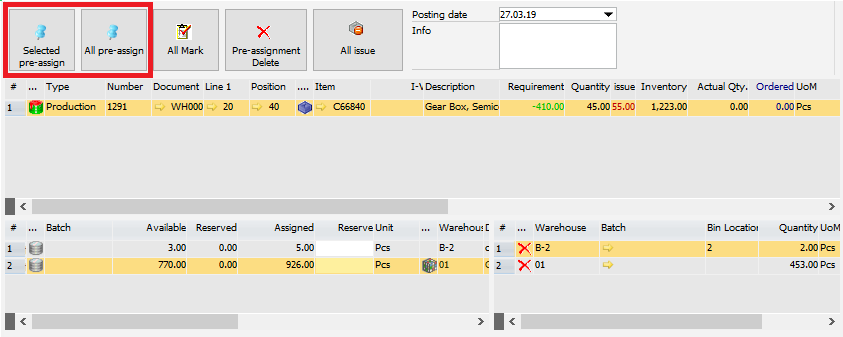

The window is based on the Beas Reservation/Allocation window structure with only one bottom screen section.

Window settings are available.

Window wmspickproduction.psr

|

![]() Requirement area – Field descriptions

Requirement area – Field descriptions

|

|

|