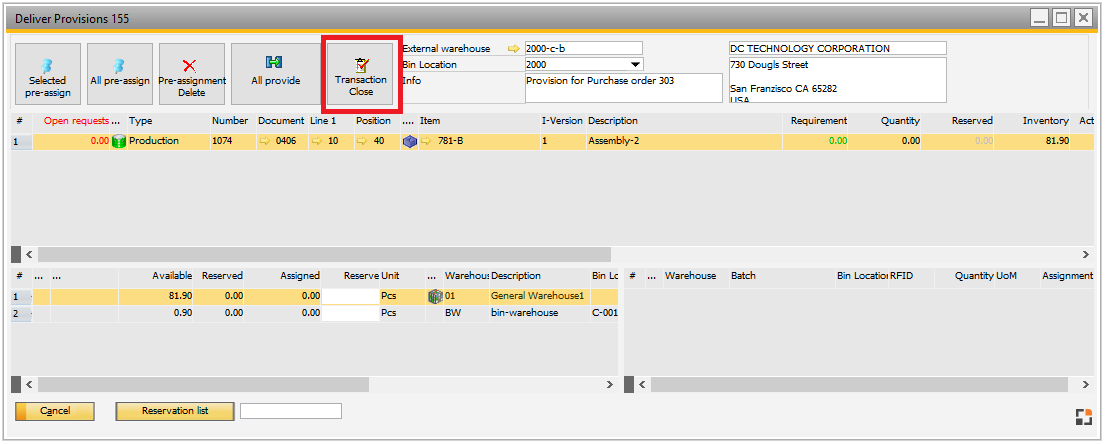

In this window you can deliver provisions for an external operation.

PATH: Production > External production > Provisions > Open an entry

Window reservation_set_master_psr

The allocation/deliver function is used to transfer material needed for a work order from a default warehouse to an allocation warehouse. The material is also reserved for that work order. When doing an allocation, Beas creates a transfer document. Usually this is cost-neutral and not assigned to the work order.

PATH: Production > Work Orders > right-click an allocation in the WO structure / right-click an item > "Allocation".

Reservation system needs to be activated Allocation warehouse has been defined as type

|

Transfer from standard item warehouse or from warehouse defined in BOM to the allocation warehouse. Goods are transferred via SAP Business One-transfer function to the allocation warehouse, a reservation is created. After finishing the product: manual or automatic backflushing of the material.

See: Reservation system |

Window structure

The active field is always the entry field in the lowest line. This can be used for registration via scanner. There are two settings: Production > Material posting > Backflushing > Material posting with scanner.

Active: A matching batch or serial number is searched. If an entry is found, it will be used and the required quantity is accepted. If no entry is found, an error message is issued: no entry found. If the entry is blocked, (batch status, blocked bin location) the entry is not accepted, a message is issued.

Inactive: Beas searches for the following entries: Batch number: field is selected, the cursor is set to quantity field. Serial number: quantity is accepted immediately. Item: entry selected, cursor is set to quantity field.

If no matching entry was found and the entry is numeric, the current entry is accepted including the quantity. Error messages are issued in no case.

See Configuration wizard – Material posting with scanner

beas9.0-000-003-006, beas9.0-000-002-024, fert_scanbatchqty (J) |

Fields right of the ribbon

Only some fields explained in the table below are displayed, depending on the work flow.

Field |

Meaning |

Posting date |

Postings: select the posting date. |

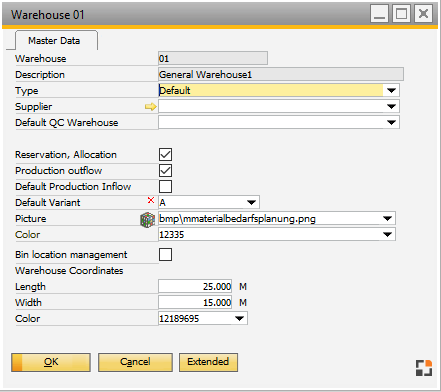

Allocation warehouse |

Allocation: allocation warehouse. Setting is saved per work station. Note: this has no effect on the reservation and issue screen. See Reservation window, Material posting. |

Bin location |

Bin location of the external warehouse to which material is transferred (field is only displayed if the warehouse has bins). For reservation the definition of Bin Location is mandatory |

Address |

Address of the external warehouse. |

Functions in upper ribbon:

Button |

Meaning |

|||||||||||||||||||||

Pre-assign Quantity (manually)

|

- visible in WO Stock Transfer Request window With this option the user can manually pre-assign quantities for each material line based on the equivalent amount of the parent product. In the quantity field you can specify the quantity of the parent product. Apply changes for the selected lines.

See WO Stock Transfer Request creation process. |

|||||||||||||||||||||

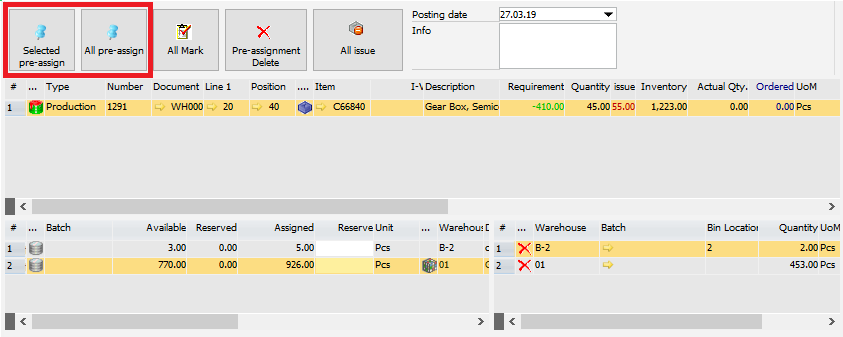

Pre-assign |

|

|||||||||||||||||||||

Pre-assign all |

All entries are marked and then reserved. See Pre-allocate. |

|||||||||||||||||||||

Delete reservations |

All reservations are deleted |

|||||||||||||||||||||

With shortage: Display only items which still need to be allocated Only allocation ID: Only items with activated allocation ID Standard: All items which need to be allocated All: All items. Also items which do not need to be allocated |

||||||||||||||||||||||

Create Request |

- visible in WO Stock Transfer Request window. With this button you can create a stock transfer request by pre-assigning quantities for the requested materials of a work order. The created request is then displayed in the work order structure. |

|||||||||||||||||||||

All Allocate |

- visible in External Production - Deliver Provisions Transfer all provisions |

|||||||||||||||||||||

Close Transaction |

- visible in External Production - Deliver Provisions Close transaction when creating the Goods Receipt Purchase Order document. |

Right-click menu

Item |

Meaning |

Reservation list |

Opens the reservation list |

Reservation delete |

Deletes existing reservations. |

Filter: All |

Lines which have been posted are also displayed. |

Filter: only requirement |

Standard view. Only lines which have not been posted are displayed. |

Buttons below

Button |

Meaning |

Reservation list |

Open the reservation list. |

Inventory history |

Open inventory history for the selected item. |

|

back to list of provision parts

back to work order general