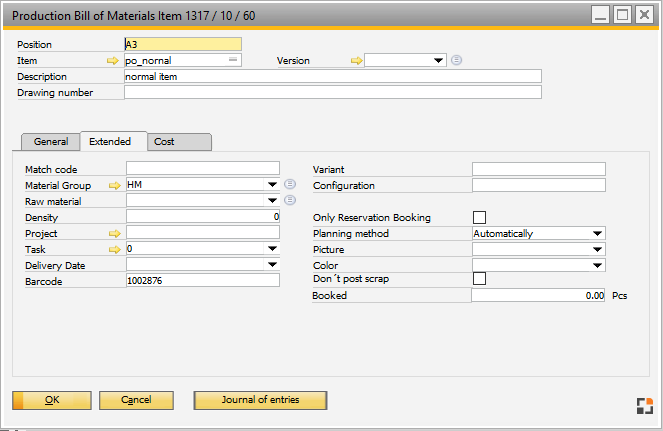

In the "Extended" tab you can edit additional information for the WO BOM position.

PATH: Production > Work orders > "Edit" work order > Work order document "Positions" tab > "Edit" selected work order position > "Bill of Materials" tab > "Edit" WO Bom position > "Extended" tab.

Window fert_ftstlpos_edit.psr

Master Data information

Field |

Meaning |

|

Match code |

Optional |

|

Material group |

Selected material group |

|

Raw material |

Selected raw material |

|

Density |

Density |

|

Project |

Project link. Display from work order item. Read only. |

|

Task |

Refers to project tasks. Can be used to link the material item to a project task. |

|

Delivery date |

Planned delivery date. Only info. |

|

Barcode |

|

|

Variant |

Variant (from assembly) |

|

Configuration |

Configuration ID (from assembly) |

|

Issue remains |

Charge-off batch stock from a quantity See item - edit BOM |

|

Only reservation booking |

Post only reserved items. See item - edit BOM |

|

Image |

Stored Image. |

|

Color |

Stored Color. |

|

Receipt |

Already posted quantity. |

|

Issue |

Already posted quantity. |

|

Don't post scrap |

Check box to set not to post scrap |

Breakdown |

||

|---|---|---|

Breakdown with Variant |

|

|

issue batch remains |

|

|

Only reservation booking |

|

|

Don't post scrap |

||

Planning method |

|

|

Synchronization |

|

|

Icon / Color |

Determine the icon and color of the BOM position to be displayed. |

|

Receipt / issue |

Only production: display the booked quantity. |