|

Available with Issue, Receipt, Allocation for production, Pick and pack, Stock information license.

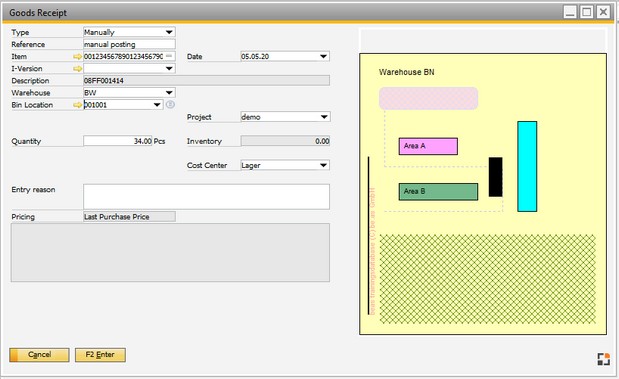

This app opens the window for manual postings > Goods receipt. The Type is automatically set to "Production" and therefore Reference field appears as a Work order filter.

With manual postings the inventory can be adjusted without a document.

For example, after the stocktaking, part of the stock was not counted, the missed amount can then be manually posted.

The following manual posting options are available:

Only one item can be added per manual posting procedure.

The posting is a simplified operation to be used in production and some information is omitted.

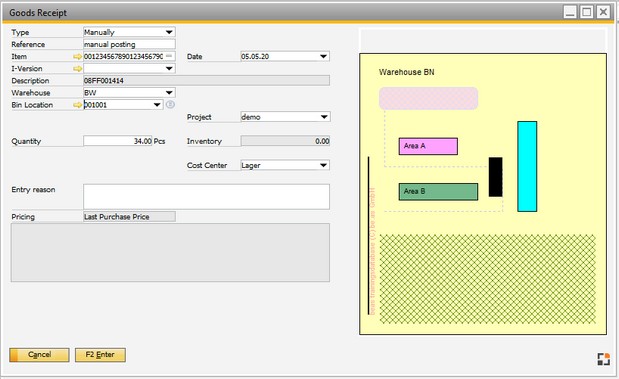

Window mw_manuell_buchen.psr

Posting types

There are different types of postings

|

|

|

Manual

|

Used to report a manual posting. This option uses the accounts set in Beas general parameters. These accounts can be different from the correction option.

|

Production

|

Assigned to a production order. Entry of the production document and the position or BOM position is necessary. After choosing the position, the item is inserted automatically. The posted quantity is displayed and evaluated in the production structure views.

In the Production order field the following can be entered:

| • | work order position bar code |

The entry is processed according to its type.

Production posting type special case:

|

Correction

|

Used to report adjustment of remaining stock (evaporation, scrap, and so on). This option uses the accounts set in Beas general parameters.

|

Inventory

|

Uses the same accounts as the Manually option, but the inventory adjustment posting type is entered in the comment field in the goods issues document.

|

|

Window structure, field description Window structure, field description

The input window structure changes, depending on the entered information. Related fields become available depending on whether receiving, issuing or transferring takes place, whether a batch or a serial number is entered or whether there are different inventories or Production UoMs. The same applies to bin locations. If the bin location has been created, they are displayed for selection.

|

|

|

Work order

|

Displayed only if Production type was selected.

Document number, line and position. If new is selected from the position drop-down, "-1" is displayed in the field. A new work

order position can be entered instead of the -1, the item and quantity can be selected.

1. Field - work order number

The work order can be selected from the drop-down list or scan:

| a) | The work order document number (Data field: beas_fthaupt.belnr_id). |

| b) | The work order bar code (9 digits). It is used for posting in the assembly. The second and third field is filled automatically. (Data field: beas_ftpos.barcode) |

| c) | The material bar code. Used to post material. (Data field: beas_ftstl.nummer) |

(BOM - Extended - Bar code)

2. Field - work order line number

Select work order item to be issued or posted (Data field: beas_ftpos.belpos_id). Only items allowed to post are available (items not closed or blocked)

3. Field - work order position number

Select the BOM item to be posted (Data field: beas_ftstl.pos_id).

Only BOM positions that are not closed been closed, with warehouse oriented items are allowed.

Special case:

0 or empty = the assembly is posted.

-1 = a new BOM item is generated.

Blocked BOM positions cannot be selected, but the position number can be manually entered or scanned via barcode. For postings, the respective authorizations are required.

|

It is possible, to issue material and to create a BOM position at the same time, if the position does not exist.

Select the work order document and the assembly, and then select "new" in the third field.

|

|

|

|

Item

|

Item number.

|

I-Version

|

(beas 9.1 PL: 08)

|

Warehouse

|

Warehouse that item is posted to.

Note: As of Beas Manufacturing 9.3 PL03, Produmex WMS warehouses are supported for Beas transactions.

|

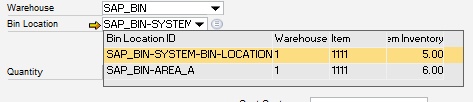

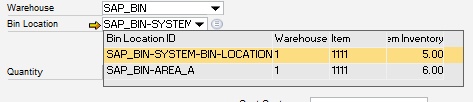

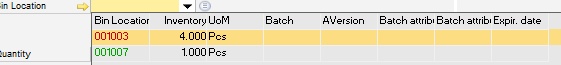

Bin location

|

Beas supports WMS, Beas, and SAP Business One Bin Management (Beas 9.3 PL3)

The field has the following components:

Orange arrow  : :

List of all bins where the item is located.

Selection (Drop-down)

A list opens to select the desired bin location.

The selected drop-down option displays the following information in receipt documents:

| • | First item in this bin location |

| • | Stock of the first item in this bin location |

The list can be modified in the Configuration wizard.

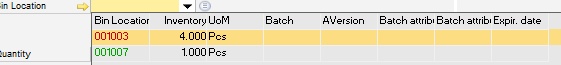

The selected drop-down option displays the following information in issue documents:

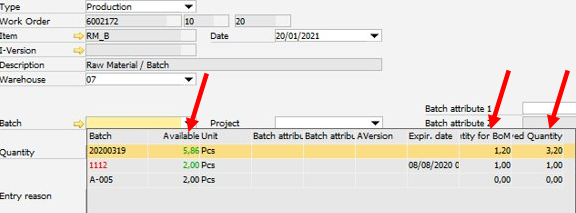

| • | All stock information of all bin locations with batch- and serial number information. |

The dropdown contains information on reserved quantities in 3 columns:

The batch entry in the list is displayed in RED color if the Batch is not free.

Quantity-related information:

Field

|

Description

|

Available

|

Available quantity is = Inventory - reserved quantity + reserved quantity for current work order position.

This quantity is displayed in GREEN, if quantity is reserved for the currently used Bill of Materials position.

|

Reserved for BoM

|

Reserved Quantity for this BoM Position

|

Reserved Quantity

|

Total reserved Quantity

|

|

Select or List - Icon

By using the selection icon, an adjustable selection list opens. Window settings and templates are supported.

The Definition of the bin location is mandatory.

|

If the bin location is not defined, Beas uses the default bin location for this item for the specified transaction type.

This is entirely managed by SAP Business One.

Drop-down for volume or weight is not supported. Columns are always 0.

beas 9.3 PL 2

|

Bin location is mandatory.

Drop-down for volume and weight not supported.

|

This list can be modified in the Configuration Wizard. General manipulation is possible using the stockmanagement.src file or window-related changes using Windowevent setbindropdown.

The following priorities are considered:

| 1. | Window-related customization (windowevent setbindropown) |

| 2. | General changes (stockmanagement.src) |

| 3. | Settings in the Configuration wizard |

In the e_bindropdownbsl variable, the ODATA command can be defined.

It is beneficial to use the Beas service layer, because Beas supports different warehouse systems that use different tables and logic.

The standard functions for receipt and issue are as folows:

file stockmanagement.src

function binreceiptdropdown

setvar=e_bindropdownbsl=BinLocation(<e_binwhscode,bsl>)?$mask=1

end function

function binissuedropdown

setvar=e_bindropdownbsl=WareHouseStock(<e_binwhscode,bsl>)?$select=BinLocation/BinCode,BinLocation/BinColor,OnHand,UoMCode,Batch,IVersionId,BatchAttribute1,BatchAttribute2,ExpirationDate&$filter=ItemCode eq <e_itemcode,bsl> and OnHand gt 0

end function

For receipt, use BinLocation.

For issue, use WareHouseStock.

For more information, see Beas Service Layer documentation.

Example

-- file stockmanagement.src --

// BinReceipt: Show all Bin Locations, ordered by OnHand descending, BinCode ascending:

function binreceiptdropdown

setvar=e_bindropdownbsl=BinLocation(<e_binwhscode,bsl>)?$select=BinLocation/BinCode,BinLocation/BinColor,OnHand&$orderby=OnHand desc,BinLocation/BinCode asc

end function

// BinIssue: Show only Bin Locations where OnHand > 0 of the selected ItemCode, ordered by OnHand descending, BinCode ascending:

function binissuedropdown

setvar=e_bindropdownbsl=WareHouseStock(<e_binwhscode,bsl>)?$select=BinLocation/BinCode,BinLocation/BinColor,OnHand,UoMCode,Batch&$filter=ItemCode eq <e_itemcode,bsl> and OnHand gt 0&$orderby=OnHand desc, BinLocation/BinCode asc

end function

|

Attention:

This is available only up to Beas 9.3 PL 1 – in maintenance.

This list can be modified in the Configuration Wizard. General manipulation is possible using the stockmanagement.src file or window-related changes using Windowevent setbindropdown.

The following priorities are considered:

| 1. | Window-related customization (windowevent) |

| 2. | General changes (stockmanagement.src) |

| 3. | Settings in the Configuration wizard |

Window-specific adjustments:

Call the setbindropdown user event. The dropdown:bin_from variable can be defined.

Example:

windowevent setbindropdown

setvar=e_bindropdown=ddsql=select "BINCODE" from "BEAS_WHSBIN" where "WhsCode"=<e_binwhscode,dbstring> order by "STORAGESORT"

end event

Note: This window event is supported in every window where the selection field is available.

General adjustment

Use the stockmanagement:binreceiptdropdown() fuction to store a custom drop-down configuration.

file stockmanagement.src

function binreceiptdropdown

setvar=e_bindropdown=ddsql=select "BINCODE" from "BEAS_WHSBIN" where "WhsCode"=<e_binwhscode,dbstring> order by "STORAGESORT"

end function

|

|

|

LUID

|

Define LUID number.

See

LUID behavior settings.

WMS Production receipt

|

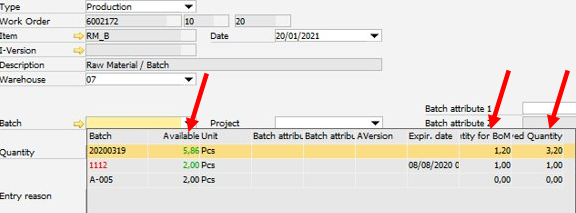

Project

|

Link to an SAP Project code. The default value comes from the project linked to the work order. If continued stock is active in the database, the project code is included in the journal entry.

|

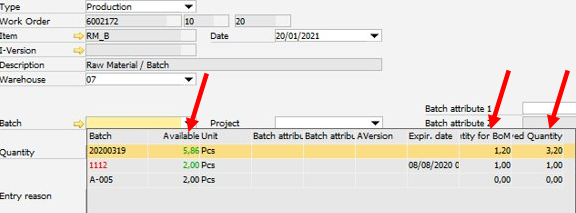

Batch/Series

|

Click the orange arrow to generate a new batch or serial number. After this batch or serial number is firmly assigned and the arrow is hidden.

The dropdown contains information on reserved quantities in 3 columns:

The batch entry in the list is displayed in RED color if the Batch is not free.

Quantity-related information:

Field

|

Description

|

Available

|

Available quantity is = Inventory - reserved quantity + reserved quantity for current work order position.

This quantity is displayed in GREEN, if quantity is reserved for the currently used Bill of Materials position.

|

Reserved for BoM

|

Reserved Quantity for this BoM Position

|

Reserved Quantity

|

Total reserved Quantity

|

|

See:

Production – Batch administration

Materials management – Batch administration

|

Date

|

Posting date of the document. The default value is the today variable.

|

Quantity

|

The quantity to be issued.

Serial numbers:

For serial numbers only a quantity of 1 can be entered.

Serial number reservation

Posting in a production assembly any quantity can be entered if the serial number determination is set to "automatic" for the respective item and the serial numbers have been reserved. In this case, a window opens where the serial numbers can be selected.

See:

Configuration wizard – Production – Serial numbers

Concept Serial number reservation

Item master – Series tab

|

Conv-Quantity

|

Only displayed, if the consumption unit does not match the warehouse unit of the item.

See consumption unit

The entered quantity is converted to warehouse unit. Length, width and height are indicated. These parameters are considered, using the conversion formula.

See Conversion

|

|

Close

|

Only visible, if a production assembly is posted.

Set automatically, as soon as the planned quantity is reached. Manual change is possible.

The behavior can be defined in Configuration wizard - Close assembly automatically.

If the option is active, the production position is closed after receipt.

|

|

Cost center

|

|

Entry reason

|

Free text to add information.

|

Pricing

|

Production Assembly

|

Settings apply from Production > Valuation and booking of the assembly > Valuation

|

Post in positive BOM item

|

Settings apply from Materials management > post in manually > Purchased items pricing booking

|

Post in negative BOM item

|

Settings apply from Calculation > Precalculation > Pricing negative BOM

|

Other posting

|

Settings apply from Materials management > Post in manually > Purchased items/In-house production pricing booking

|

|

|

Additional fields are available at transfer:

|

|

|

To

|

Define the warehouse to transfer to. Define the warehouse to transfer to.

The To warehouse can only have the same entry as Warehouse if it is a bin location inventoried warehouse. A pure bin location transfer is then possible.

Note:

A bin location move instead of a SAP Business One - Transaction runs at a bin location transfer. There is no account movement, no calculation of FIFO prices or average prices. The bin location entry is changed. An entry is created in the bin location-movement protocol.

|

|

Bin Location

|

|

|

|

|

|

Cancel

|

Cancel the process.

|

Batch list (F3)

|

Inventory list by batches

This button is only visible, if a batch related item is selected.

|

Book (F2)

|

Start the booking process.

|

|

Every posting process creates several events, which can be set as default or customized (see customizing).

Posting finished products (assigned to a work order), calls the assignment program which controls closing, pricing, and batch administration. An external materials management system can also be connected and used in parallel.

|

Help URL: https://help.beascloud.com/beas202102/index.html?terminal_post_in_for_production.htm

|

![]()

![]() Window structure, field description

Window structure, field description