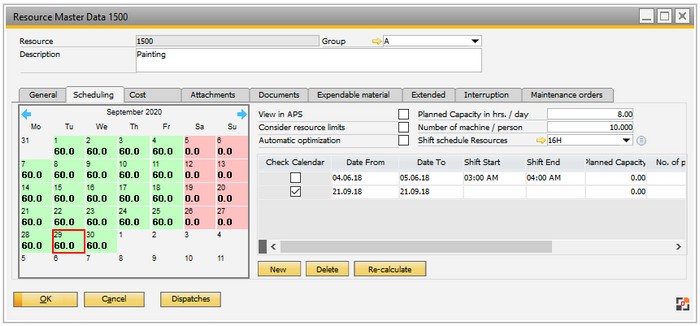

The utilization or availability of a resource can be set per day. Since a resource can also constitute a personnel group, this function can also be considered as the vacation schedule of a personnel group.

PATH: see "Edit resources".

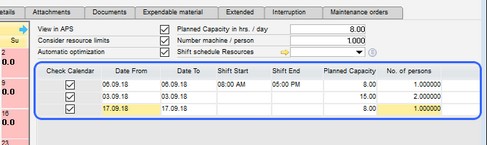

Window stamm_arbplatz_edit.psr

Field |

Meaning |

||||

View in APS |

|

||||

Consider resource limits |

|

||||

Automatic optimization |

|

||||

Planned Capacity in hrs. / day |

|

||||

Number of machines / persons |

|

||||

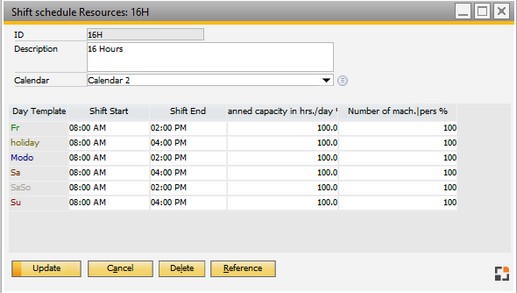

Shift schedule Resources |

|

Right to the resource calendar exceptions for certain periods can be entered. These are displayed in a table.

Window stamm_arbplatz_edit.psr

Field |

Meaning |

Date from/to |

Period in which the exception applies. |

Check calendar |

Check mark active: the factory calendar is not taken into account at capacity calculation.

If the factory calendar is NOT taken into account, the following formula applies: Total net capacity is (planned capacity in hours/day) * (number of mashines / persons) *

If the factory calendar is taken into account, the following formula applies: Total net capacity is (planned capacity in hours/day) * (number of mashines / persons) * ( %-value as per factory calendar). |

Shift Start/End |

Shift start/end. If set, the shift stored in shift schedule for resources is overwritten. For further information See Shift schedule for resources.

By leaving the field empty, the default shift applies. Attention: Shift over midnight is not possible. |

Planned capacity |

Overwrites the planned capacity for this shift in the given period. |

Number of persons |

Overwrites the number of single resources (see above) in the given period. |

Reason |

Reason for the exception. |

See

back to edit resource