|

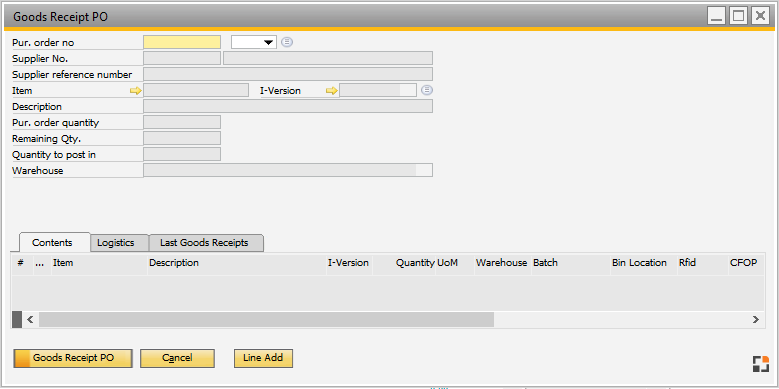

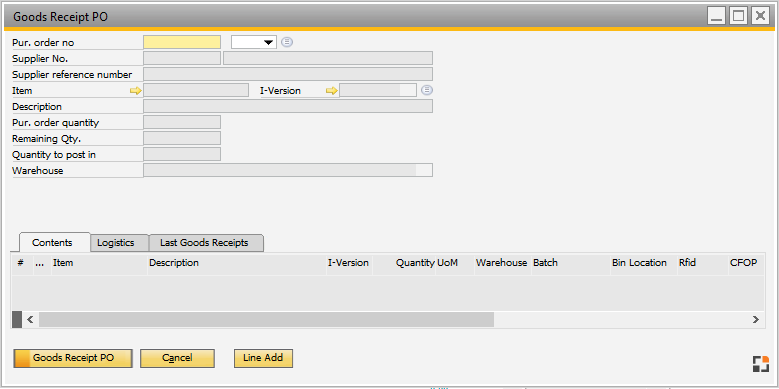

Goods receipt is a replacement function for SAP Business One – Purchase > Good receipt PO.

This function is ideal to be employed directly at the goods receipt location and supports, apart from supplied parts lists, optimal batch support and serial numbers support, quality control, label printing and some other important functions. Good receipt creates a regular goods receipt delivery note in SAP Business One.

Multiple Goods Receipt purchase window (default)

Window mw_goodsreceiptpo_edit.psr

Special Functions:

| • | Several purchase order rows can be posted in with one goods receipt document |

| • | Posting in several batches, only one goods receipt row is created. |

| • | Summary of different purchase orders is not possible |

| • | All good receipts which has been created on this station via this window are displayed in tab "previous good receipts". Own good receipt function created via SAP B1 or good receipts, which has been created on other stations, are not be displayed here. |

| • | Support Beas, SAP and WMS Bin Management |

There are two functions: You can set up the one to be used in Configuration wizard > Materials management > Goods receipt > Goods receipt type.

Attention:

Do not use this Variant. This window is in maintenance and this will not be supported in the future.

This is still available only for reasons of compatibility and will be replaced by the "Multiple".

| • | Per purchase order row one goods receipt is created. |

| • | For each batch a goods receipt is created. |

| • | Several serial numbers can be posted in with one goods receipt. |

| • | All new functionality from SAP after SAP 9.0 NOT supported |

|

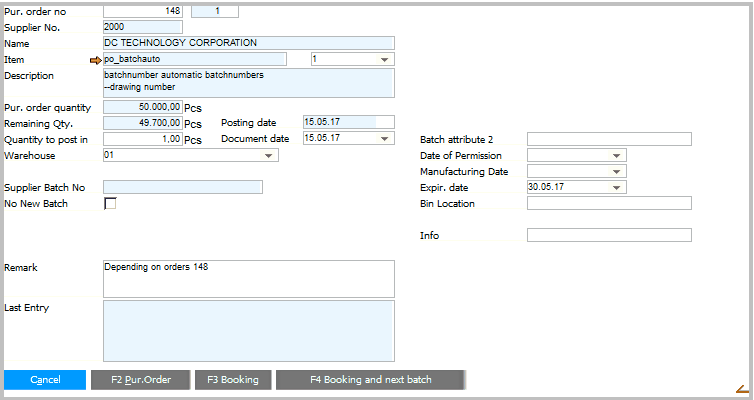

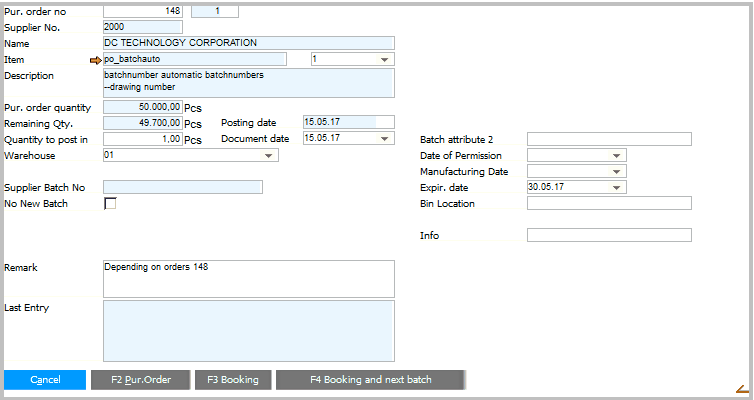

Apart from the order information, additional fields are shown – depending on the item type.

|

|

|

Purchase order number

|

Select from open purchase orders or purchase requests (switch on the right to open the window open purchases)

You can insert the number manually or you can choose this from a list.

If you insert the number manually, you can insert only a Purchase order, not Pre-Invoice or Quotation number.

If a Document number exists more than once, Beas uses the last document.

|

Supplier number

|

Supplier number

|

Supplier reference number

(only for GO type multiple)

|

Free text

|

Name

|

Supplier name

|

Item

|

Item

|

Item description

|

Item description

|

Pur. order quantity

|

Purchases quantity

|

Remaining quantity

|

Remaining quantity

|

Quantity to post in

|

Quantity to be posted in now. Quantity to be posted in now.

Warning: All quantities are shown in the purchasing UoM.

The number of decimal places depends on Master data – Units of measure.

If per line serial numbers are entered, this field displays the current total quantity according to the sum of all quantities from entries below.

Notes on serial numbers:

In item master series tab you can set up whether serial numbers are generated automatically or not.

Serial numbers are generated manually.

If serial numbers are entered per line, these fields show the current total quantity.

Automatically generated serial numbers.

The quantity can be specified. Serial numbers are generated only at the moment of goods receipt.

Number generation is set up in Configuration wizard – Materials management - Goods receipt – Serial numbers.

|

|

Date of entry (Only type "single")

|

The date for the entry. It is normally the current day.

Depending on the settings (goods receipt type simple or multiple) this field is to be found under logistics tab.

|

Reference date

|

Corresponds to Tax date in SAP document.

|

Warehouse

|

Warehouse stored in purchase order.

Representing the primary inventory.

Depending on the setting, the quality control warehouse is set up automatically.

If a goods receipt warehouse is defined, depending on the rules the associated goods receipt warehouse is entered.

Notes:

SAP Bin Warehouse supported. But it is not possible to make a receipt on different Serial- or Batch Numbers with the same base document line. We are working on this limitation.

WMS Bin management is not supported.

See:

Configuration wizard – Quality control – Goods receipt

Edit warehouse master data

|

|

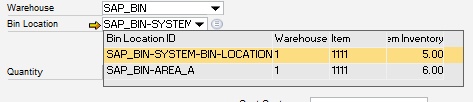

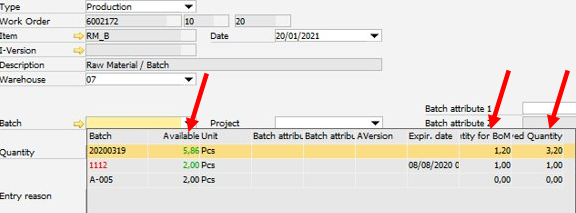

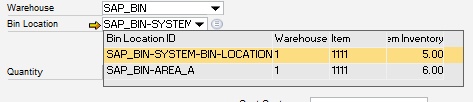

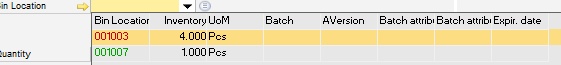

Bin location

|

Determines to which bin location the goods are posted at receipt. Determines to which bin location the goods are posted at receipt.

Supported: Beas and SAP Bin Management

See Receipt on bin location

Beas supports WMS, Beas, and SAP Business One Bin Management (Beas 9.3 PL3)

The field has the following components:

Orange arrow  : :

List of all bins where the item is located.

Selection (Drop-down)

A list opens to select the desired bin location.

The selected drop-down option displays the following information in receipt documents:

| • | First item in this bin location |

| • | Stock of the first item in this bin location |

The list can be modified in the Configuration wizard.

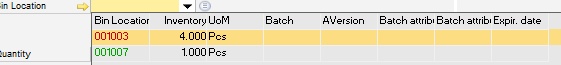

The selected drop-down option displays the following information in issue documents:

| • | All stock information of all bin locations with batch- and serial number information. |

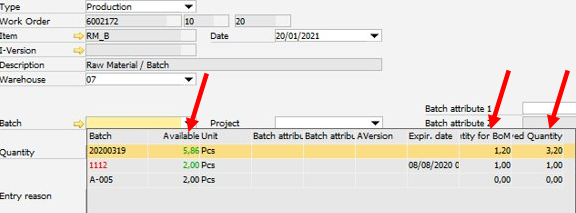

The dropdown contains information on reserved quantities in 3 columns:

The batch entry in the list is displayed in RED color if the Batch is not free.

Quantity-related information:

Field

|

Description

|

Available

|

Available quantity is = Inventory - reserved quantity + reserved quantity for current work order position.

This quantity is displayed in GREEN, if quantity is reserved for the currently used Bill of Materials position.

|

Reserved for BoM

|

Reserved Quantity for this BoM Position

|

Reserved Quantity

|

Total reserved Quantity

|

|

Select or List - Icon

By using the selection icon, an adjustable selection list opens. Window settings and templates are supported.

The Definition of the bin location is mandatory.

|

If the bin location is not defined, Beas uses the default bin location for this item for the specified transaction type.

This is entirely managed by SAP Business One.

Drop-down for volume or weight is not supported. Columns are always 0.

beas 9.3 PL 2

|

Bin location is mandatory.

Drop-down for volume and weight not supported.

|

This list can be modified in the Configuration Wizard. General manipulation is possible using the stockmanagement.src file or window-related changes using Windowevent setbindropdown.

The following priorities are considered:

| 1. | Window-related customization (windowevent setbindropown) |

| 2. | General changes (stockmanagement.src) |

| 3. | Settings in the Configuration wizard |

In the e_bindropdownbsl variable, the ODATA command can be defined.

It is beneficial to use the Beas service layer, because Beas supports different warehouse systems that use different tables and logic.

The standard functions for receipt and issue are as folows:

file stockmanagement.src

function binreceiptdropdown

setvar=e_bindropdownbsl=BinLocation(<e_binwhscode,bsl>)?$mask=1

end function

function binissuedropdown

setvar=e_bindropdownbsl=WareHouseStock(<e_binwhscode,bsl>)?$select=BinLocation/BinCode,BinLocation/BinColor,OnHand,UoMCode,Batch,IVersionId,BatchAttribute1,BatchAttribute2,ExpirationDate&$filter=ItemCode eq <e_itemcode,bsl> and OnHand gt 0

end function

For receipt, use BinLocation.

For issue, use WareHouseStock.

For more information, see Beas Service Layer documentation.

Example

-- file stockmanagement.src --

// BinReceipt: Show all Bin Locations, ordered by OnHand descending, BinCode ascending:

function binreceiptdropdown

setvar=e_bindropdownbsl=BinLocation(<e_binwhscode,bsl>)?$select=BinLocation/BinCode,BinLocation/BinColor,OnHand&$orderby=OnHand desc,BinLocation/BinCode asc

end function

// BinIssue: Show only Bin Locations where OnHand > 0 of the selected ItemCode, ordered by OnHand descending, BinCode ascending:

function binissuedropdown

setvar=e_bindropdownbsl=WareHouseStock(<e_binwhscode,bsl>)?$select=BinLocation/BinCode,BinLocation/BinColor,OnHand,UoMCode,Batch&$filter=ItemCode eq <e_itemcode,bsl> and OnHand gt 0&$orderby=OnHand desc, BinLocation/BinCode asc

end function

|

Attention:

This is available only up to Beas 9.3 PL 1 – in maintenance.

This list can be modified in the Configuration Wizard. General manipulation is possible using the stockmanagement.src file or window-related changes using Windowevent setbindropdown.

The following priorities are considered:

| 1. | Window-related customization (windowevent) |

| 2. | General changes (stockmanagement.src) |

| 3. | Settings in the Configuration wizard |

Window-specific adjustments:

Call the setbindropdown user event. The dropdown:bin_from variable can be defined.

Example:

windowevent setbindropdown

setvar=e_bindropdown=ddsql=select "BINCODE" from "BEAS_WHSBIN" where "WhsCode"=<e_binwhscode,dbstring> order by "STORAGESORT"

end event

Note: This window event is supported in every window where the selection field is available.

General adjustment

Use the stockmanagement:binreceiptdropdown() fuction to store a custom drop-down configuration.

file stockmanagement.src

function binreceiptdropdown

setvar=e_bindropdown=ddsql=select "BINCODE" from "BEAS_WHSBIN" where "WhsCode"=<e_binwhscode,dbstring> order by "STORAGESORT"

end function

|

|

|

Expiry date

|

Only possible for batch or serial number items. Determines the expiration or end of warranty date. This date is calculated automatically. Setup in Item master > batch tab or Serial number tab

|

Supplier Batch No

|

Only possible for batch or serial number items.

A supplier batch number can be specified here.

At batch: Entered in the field Supplier batch of the batch. If the field "No new batch" is active, the batch entered here is also used as internal batch number.

For serial number: Next to the serial number, the batch is entered in the field "Batch".

|

Serial number

|

Different depending on selected "Type "in Configuration wizard.

| Goods receipt type single |

There are three options:

1. Automatic generation

If there is no entry, the numbers are generated automatically. Automatic number generation is set up in Configuration > Materials Management.

2. Manual entry

The numbers can be separated with commas, e.g. 10004,100023,100Z3 etc.

3. Manual determination of the automatic generation

A template is defined which determines the structure of the serial numbers. *The counter is enclosed by { and } .

Example of piece count 3:

{0010} results in 0010, 0011, 0012

A5-3{002}X results in A5-3002X,A5-3003X,A5-3004X

|

| Goods receipt type multiple |

1. Automatic generation

No serial number can be entered. Quantities > 1 not possible. Serial numbers are generated with the document.

2. manual determination

Serial numbers are entered or scanned and confirmed with TAB/ENTER. Jump to next entry.

If a lot of serial numbers are to be entered, numbers can be added one by one: after one click the next serial number is added as a new line. Using bar code scanners, the scanner can be configured for adding a key after each read. Then the user only has to read all bar codes – no more action is needed. After reading has been finished, click on "goods receipt" button to create the document.

This function is only allowed with the following parameters: poincomingtyp set to "M". It works with manual serial items only, because for automatic serial items the window does not show a message with the complete serial number information.

|

|

|

Batch

|

This field is only visible if "Manual batch entry" or "Batch according to material" has been set in the Batch tab of the item master.

The batch number for the item to be posted can be defined here.

The quantity and the batch are indicated on "Add row" and then the next batch is captured if multiple batches are posted.

Capture of more batch attributes

1. Right-click on the list.

2. Select Window settings.

3. Fields "Batch attribute 1" as well as all other fields, which are required are set to "Visible" and "Changeable" .

4. These fields can now be edited directly in the list.

|

|

No new batch (Only type "single")

|

Only for batch items.

No automatic generation of the batch number takes place if this is activated. Instead, the batch number entered in delivery batch No. is used.

Otherwise the next number is automatically generated. For more on the batch number see Batch Management.

|

CFOP

|

Affects only Brazilian localization.

The field is displayed only if a code was stored (table OCFP).

|

|

Remarks

|

Input field for remarks.

|

Last entry

|

Last posting entry.

|

Only displayed for Goods receipt type "multiple"

Lower tabs

Content: Previously entered items which are to be posted in with the same document.

Archive: Previous goods receipts created on this work station.

Logistics:

Field

|

Meaning

|

Posting date

|

The date for the entry. It is normally the current day.

|

Remark

|

Free text.

|

Label

|

Only for compatibility reasons. Can be used for own Macros.

|

In the lower list items selected for posting are displayed. With a click on the deletion icon they can be removed. Click the goods receipt button to perform the posting.

Functions

|

|

|

Line Add

|

To post in a second item. Previously entered values are displayed below, the upper fields are emptied for new entries.

If for a document row more than one inflow was added (e.g. a second batch) the second entry is locked and the selected stock of the first row is used, because for a goods receipt only one warehouse may be selected per document line.

|

Goods receipt PO

|

Execute the posting.

|

Cancel

|

Close window without saving changes.

|

Post and new batch

|

Only for Goods receipt Type "single" and batch-managed items. If an item was entered after posting, the screen not reset. You can easily record the next batch for the same order.

|

|

Process

1. Select the order with F2.

2. Enter posting quantity.

3. Execute the order by pressing F3.

(Note: In SAP Business One-environment F-keys cannot be used. These are available only when Beas is started outside SAP Business One)

If a provision parts list exists, it is queried afterwards.

See Provision parts.

Quality control

If a quality control order is stored in the item, it is created immediately after completing the goods receipt. Depending on the settings in Configuration wizard - Quality control - Goods receipt the quality control order is opened immediately.

Automated document printing

Right-click menu > Layout

|

|

|

Preview

|

Via preview the last printed document can be viewed and printed.

|

Layout

|

Opens the Macro window. If in this window a Macro named "default" is stored, it is printed automatically after the goods receipt has been finished.

Usually, API "B1DocumentGenerate" is used to access the table "beas_document_header/beas_document_line".

If you do not want to use this API, read the internal document number from variable "e_docentry".

|

e_cardcode

|

Business partner

|

e_docentry

|

Internal goods receipt document number (docentry)

|

e_itemcode

|

Item number

|

e_batchnum

|

Generated batch number

|

e_whscode

|

Warehouse

|

e_quantity

|

Quantity

|

e_remark

|

Note

|

e_qcorder

|

Quality control order

|

|

Manual document printing

For document printing a corresponding document must be deposited in the Macro settings. The name can be freely assigned.

After creating the goods receipt document, via preview or print icon the last created document can be printed.

The following fields are filled in SAP Business One – delivery note

|

|

|

Personnel

|

Personnel number (currently logged on in Terminal, WEB Apps or linked Personnel-SAP-User

|

Beas Version

|

Beas Versions used for the posting

|

Origin

|

Origin type. For goods receipt via beas always "B"

|

|

See

Provision parts

Configuration wizard - Quality control - Goods receipt

Configuration wizard - Materials management - Goods receipt

Help URL: https://help.beascloud.com/beas202102/index.html?wareneingang.htm

|