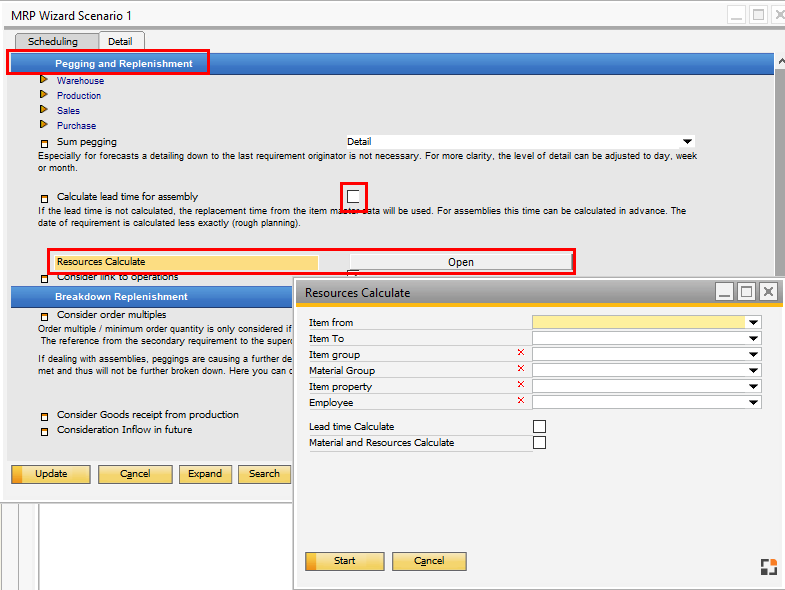

In this window, the material and resource requirement and the replenishment time can be calculated in advance for an assembly:

artikel_resourcenberechnung.psr

This window can

- Calculate lead time for item master data

- Calculate Bill of Materials and Resource, which you need for fast forecast calculation in MRP

- Create table for Material and resource with complete material and resource requirements

Which assemblies to calculate can be selected with filters on item, item group etc using a (AND)-conjunction

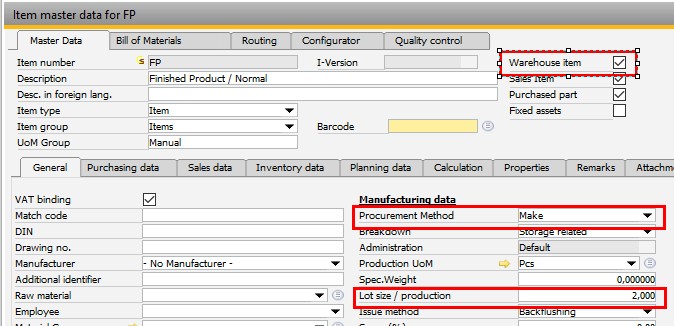

Calculation lot size: The calculation lot size is the "Lot size / production", defined in the item master data.

Calculation date: Every calculation needs a delivery day. The system uses today + 100 calendar days as delivery day. It uses this day to check which Bill of Materials position or Routing position is active (Field Extended / Valid from / to). It uses the resource planning for the next 100 days. Calculation is standard backward calculation. If the resource calendar is not calculated, the system performs this automatically (beas 2020.02)

Configuration/Variant System: Configurations and Variants (formulas and scripts) are ignored in the same way as in MRP.

Short Variant: The system always uses the short variant A.

I-Version: If item version is used, the system always uses the I-Version which was defined as default I-Version in item master data.

Function |

Description |

|

Item from / to |

|

|

Item group |

Additional filter item group |

|

Item property |

Additional filter item property |

|

Employee |

Additional filter Employee defined in item master data |

|

Calculate lead time |

|

|

Calculate material and resources |

|

To perform the computation on a regular basis, you can create an activity.

See

lead time and material requirement calculation

Item structure right-click menu

MRP – Planning scenarios – Detail – Forecasts