|

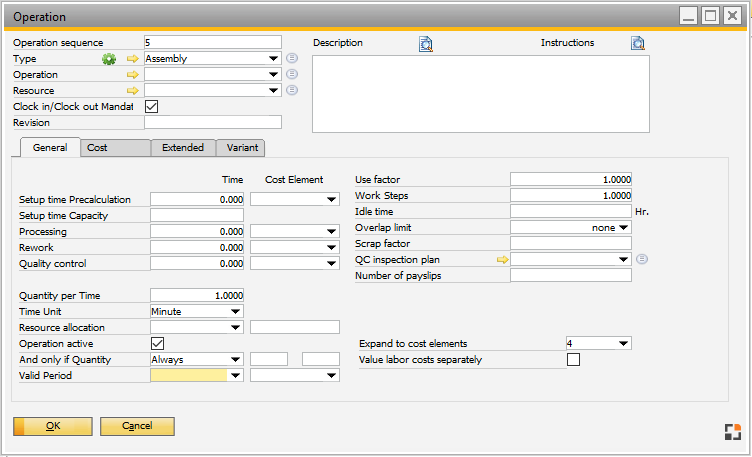

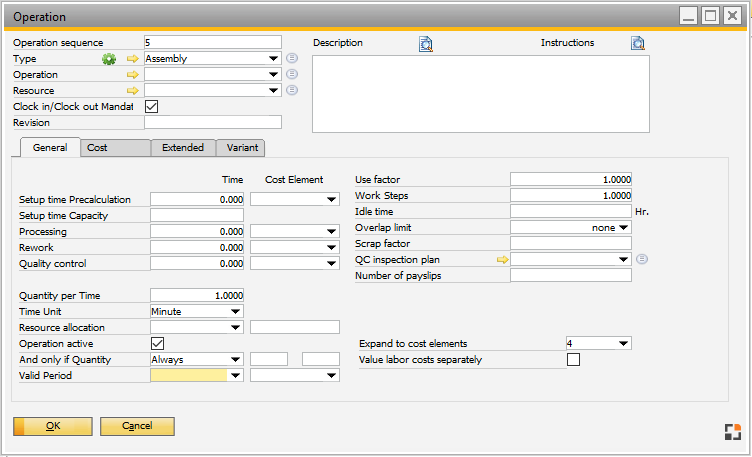

PATH: Sales A/R > Precalculation > "Open" Precalculation > "Create Operation" function

Window pk_arbplanos.psr

Header

|

|

|

Operation sequence

|

The position number is counted in increments of 10. See Configuration wizard to set up.

The field is alphanumeric with 20 digits.

Note

The order is not related to a position number, but defined in the list of BOMs by Drag&Drop. It reflects the order of entry by default. Position number cannot be unambiguous.

The field "internal position number" (BEAS_APL.POS_ID) shows the internal, continuous and unique ID.

Operation catalog:

In the operation catalog there are no operation numbers, only a catalog ID.

Precalculation, routing and work order:

In these functions you can edit the alphanumeric and the numeric position number.

BEAS_APL / BEAS_FTAPL.POS_TEXT

|

Left of the position field you can open the script window by clicking the formula icon ("display formula fields") Call-up is also possible via right-click – script.

The following variables are available:

Variable

|

Description

|

e_belnr_id, e_belpos_id

|

Work order, Work order position

|

e_aktiv

|

Routing position active J/N

|

e_routingid

|

Routing Id

|

e_itemcode

|

Itemcode

|

e_quantity

|

Quantity in regional format

|

e_source

|

"routing"

|

e_info1

|

Info for current routing position

|

See Variant generator – Script.

Note: This function is only available if the Variant generator was activated in the configuration wizard.

|

|

Type

|

Select a type from the drop-down. The  icon opens the Operation types editing window. icon opens the Operation types editing window.

|

Operation

|

Select an operation from the drop-down.The  icon opens the operation catalog definition. This can be used to adopt the information stored in the master data/operation, thus accelerating input. icon opens the operation catalog definition. This can be used to adopt the information stored in the master data/operation, thus accelerating input.

|

Resource

|

The work station, personnel group, machine or machinery group or also external operation supplier or person on or through which the operation is conducted. The  icon opens the Resources editing window. icon opens the Resources editing window.

In routing and work order routing, it is mandatory to specify a resource.

In operation catalog the resource is optional.

See Resources.

|

Active

|

Only in Work order routing position > Operation sequence XXX editing window.

|

Clock Mandatory?

|

Check box. This is important when calculating the last operation.

Definition: The last operation is the position in which "Clocking mandatory" is active for the last time.

If, for instance, the finished assembly is entered at the last operation (depending on the setting), it can be determined this way (necessary if the last operation is "Take down", for instance, but it is not clocked).

If the last operation is NOT reportable, receipt is performed here for the last reportable routing, and not for the "Receipt for last routing" option.

Example:

10 not reportable

20 reportable

30 reportable

40 not reportable

First operation is position 20 and position 30 is the last position. To the other position a report is possible, but not mandatory. Therefore these are not taken into account at the checking of rules.

|

|

Description

|

It is possible to add several lines, (max. 16 000 characters).

An external editor is opened by double-clicking the field or single-clicking the  icon next to "Description". icon next to "Description".

Customizing the routing description, Item name or additional BoM text

In addition, in the operation description, additional information on the BOM, or item, information from a formula or variant can also be stored in the description of a routing.

Placeholders can be inserted into routing descriptions for this purpose. These placeholders begin with < and end with >. All variables as well as separate formulas, tables, types of origin, etc. can be inserted.

The origin itself is defined in the placeholder using origin type and ":".

The type "Script" is used if the type of origin is not specified.

TYPE

|

Description

|

f:

|

Origin is a formula, e.g. <f:MyFormula>

|

t:

|

Origin is a table, e.g.. <t:tab4711>

|

i:

|

From assembly – item master:

e.g. <i:itemname> = Item name

|

v:

|

Variable which can be defined as necessary:

e.g. <v:var0815>

|

c:

|

Beas-script. Can be defined as a type of origin definition,

e.g.:

<c:e_belnr_id> Document number from work order,

<c:e_aplatz_id> = resource ID of the routing position

|

p:

|

Parameter from a variant. <p:so_sofa_length>

|

<c:e_quantity> * Cutting to size according to drawing number <i:u_dnr>

Color: <v:u_color>, length: <v:length>, width: <v:width>

with:

e_quantity: e.g. from beas Script the value "5" gives

u_dnr: Drawing number, e.g. "ZN 078 12345"

u_color: e.g. red

length: e.g. 20

width: e.g. 10

the following information results in the field "Description":

5 * Cutting to size according to drawing number ZN 078 12345

Color: red, length: 20, width: 10

|

|

External operations

For external operations the entered text is transferred to the service description. For further information

see collective order – description. Format needs to be considered.

|

|

V-A ... V-X

|

Right-click on the title row:

- selection: all

- selection: delete

This is to select/deselect the check boxes for all lines.

|

|

Instructions

|

The instructions field can be edited in Routing position using clicking the icon. The icon is displayed red when any text is stored. You can use different a text format, set up in Configuration wizard.

Note: Changing the text format in the Configuration Wizard has no effect in existing entries.

|

|

Note: The prices on sub-assemblies with negative quantity is set to zero for operations (including parallel operations).

back to Precalculation

Help URL: https://help.beascloud.com/beas202102/index.html?routing2.htm

|