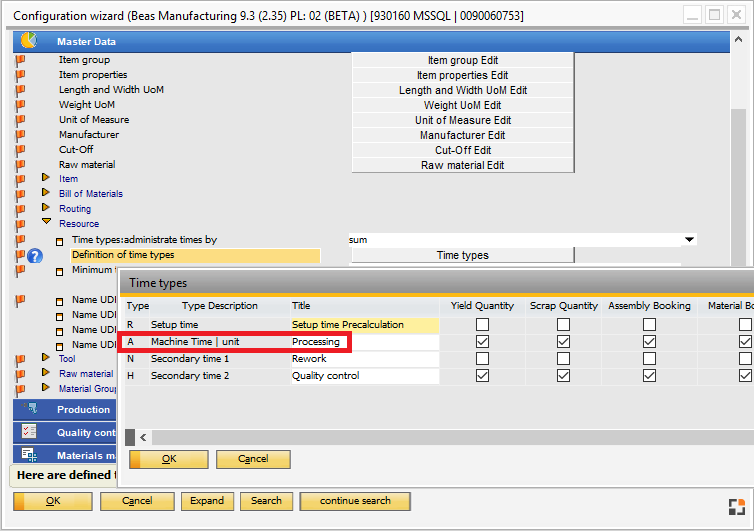

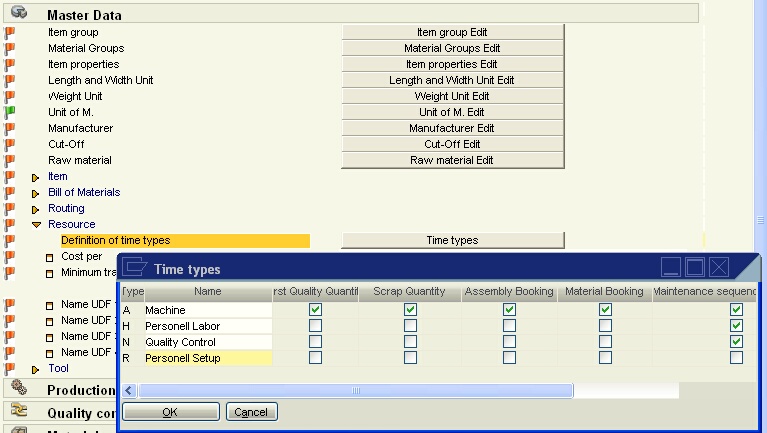

PATH: Administration > System Initialization > Configuration wizard > Master data > Resource.

Name |

Description |

|||||||||

Time types administrate times |

Variable timetyp_sp, Standard=S |

|||||||||

Definition of time types |

The 4 time types can be managed here. See time types |

|||||||||

Cost per |

As soon as a work order has been created, this setting cannot be changed and it will be hidden. Warning: A change has an immediate effect on every calculation and valuation function. If cost rates were entered to resources, and the time unit is changed here, make sure to adapt costs to the new time unit. This is not executed automatically. |

|||||||||

Defines the minimum transfer times between 2 resources. See |

||||||||||

Set Minimum Transit Time |

The "Transit time" specification is entered in all existing resources. Warning: No change log is created. Process cannot be undone. |

|||||||||

UDF1 .. UDF4 |

User-definable fields See UDF. |

Example of use with Secondary time

back to master data