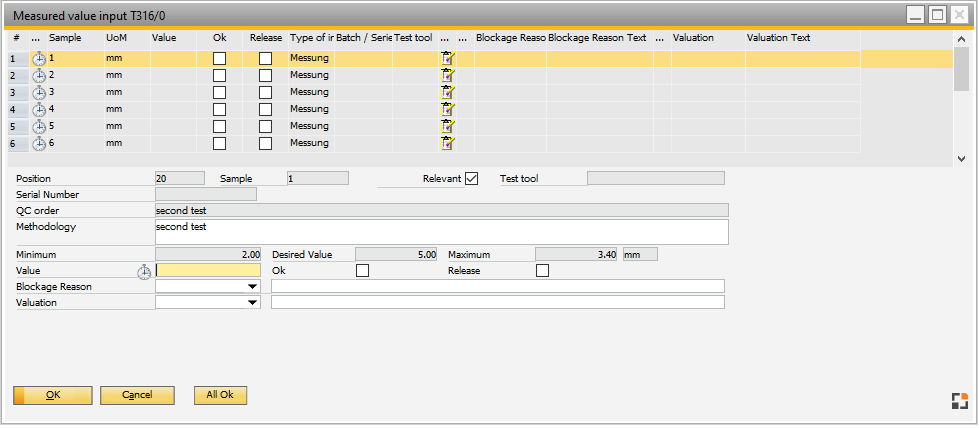

Here you can enter the measured values, OK-message, blockage reason ID for all samples.

PATH: Production > Quality Control > QC Orders > Open an entry > Input by test button > Double-click an entry

Window qs_qsftpos_allestichproben_edit.psr

The window is split in the following parts:

UPPER section: List of samples per measurement position

Field descriptions

Field |

Meaning |

|||||||

Status (...) |

An icon indicates the status of the sample. |

|||||||

Sample |

Position number |

|||||||

UoM |

Unit of Measure |

|||||||

OK |

If the entered Value falls between Min/Max, this check mark is automatically activated. |

|||||||

Release |

Check mark indicating if sample can be released. |

|||||||

Type of Input |

Attribute: you can only specify whether it is okay, and include information. |

|||||||

Batch/Serial |

Batch/Serial number |

|||||||

Blockage reason |

Stored blockage reason. |

|||||||

Valuation |

Stored valuation. |

|||||||

Blockage/Valuation text |

Enter further information for Blockage/Valuation reasons. |

Windows settings are supported.

Change Log: The Change Log displays all changes for the Quality Control order.

LOWER section: Register Measurement position for one sample

Field Descriptions

Field |

Meaning |

|

Position |

The list is sorted by this number. You can re-sort using Drag&Drop. Alphanumeric characters are allowed, position numbers can be assigned twice. |

|

Batch/Serial number |

Batch/Serial number |

|

QC-Order |

Short description for the measurement position. Right-click to select a default from the default texts. After selection, the method description is also transferred. see Manage default texts. |

|

Methodology |

Long description. Edit by double-clicking or clicking the "Description" button. |

|

Desired value, |

Target value and unit of measure (mm, kg, % etc., UoM is mandatory) |

|

Minimum / Maximum |

|

|

This option must be activated if this measuring point is relevant for the release of the test plan. Note: For automated release at least one relevant position is required. |

||

Test tool |

A test tool can be selected. Only information – no effect. No reservations or dispatches. |

|

Value |

Enter measured value in this field. If the value falls in the range between Min/Max, a green check icon |

|

OK |

If the entered Value falls between Min/Max, this check mark is automatically activated. You can manually deactivate the flag, which also deactivates the Release flag. |

|

Release |

If the entered value is "OK", the Release flag is also activated. The flag cannot be deactivated manually. |

|

Blockage Reason |

Define a blockage reason for the sample. |

|

Valuation |

Define a Valuation reason for the sample. |

Functions

Button |

Meaning |

Add |

Create a new sample with all measurement positions. |

Next/Preceding entry |

Switch to the next/previous measurement from the Input by test browse window. |

Change Log |

The Change Log displays all changes for the Quality Control order. |

Update |

Save measurements and check release. See Measurement sample. |

All OK |

Set all samples to OK. Button is displayed only, if in measurement position the option "set OK manually" was activated. |

See

Quality control order - Item master - Quality control - QC-inspection plan

Register measured values for all samples