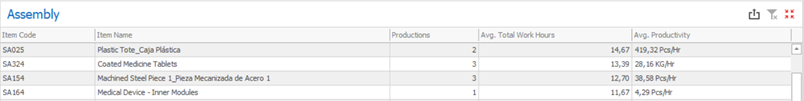

This grid displays all the produced assemblies and their average productivity per hour. The “Assembly” grid presents the following information:

a)Item Code / Item Name: Identification of the assemblies;

b)Productions: Number of times that the assemblies were produced (counting of work order positions);

c)Avg. Total Work Hours: Global average of net work hours registered for the production of each assembly, across all their routing positions. The net work hours are calculated by discounting the non-workable hours (according to the resources’ calendars) from the work hours when the time receipts last for more than one day. If the first start or last end happened before or after the resources’ available hours, those are not discounted and are considered as overtime (the discounts are only applied to the days in between the first and last days);

d)Avg. Productivity: How much of the assemblies’ unit of measures were produced during the total net work hours registered for their production.

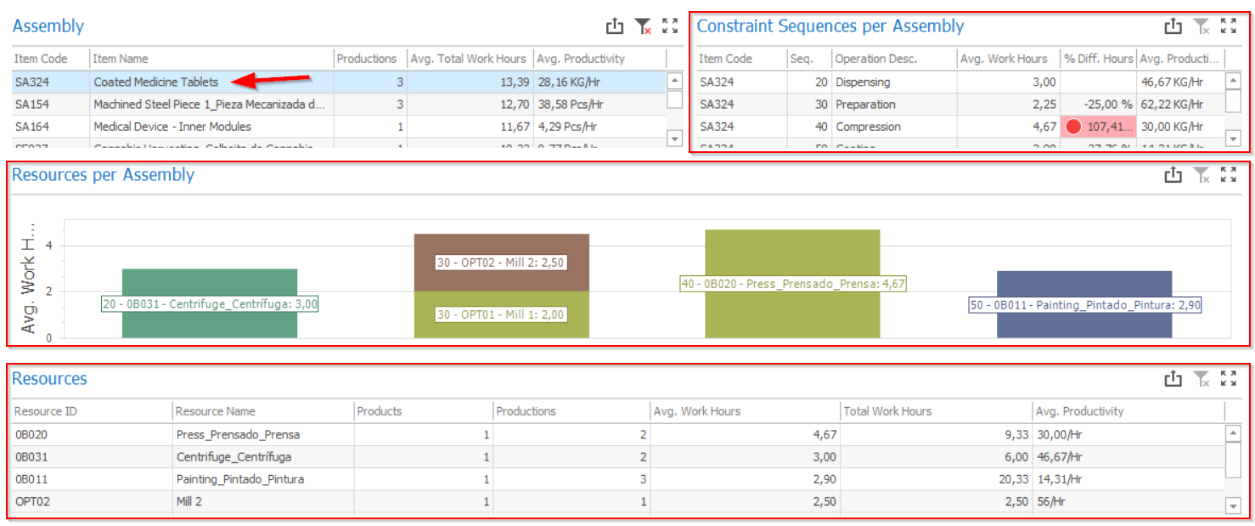

If you wish to know how much the productivity for each assembly varied during their production stages and which resources were used in their manufacturing process, you just need to click on an assembly and check the results under the Constraint Sequences per Assembly, Resources per Assembly, and Resources sections.