Beas applies this calculation method only if the following conditions are met:

•Only when forward scheduling is used in APS

•Both the APS Calculation method and the work order priority are set to 100%

•In the routing of a work order the operation is set as Simple utilization / or Percentage = 100%

•The resource linked to each of the routing positions of the Work order is set to have the master data field Number of machines/Pers = 1.

How Detailed planning works:

The detailed planning checks to the minute when a resource is available, and whether the work sequence can be completed in the available time windows.

Assumptions: our resource is the same on all routing position on the below reported examples and has a total capacity of 12 hours per day.

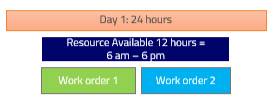

Example 1:

Work order No. 1 and Work order No. 2 start at 6am on the same date/time. Both work orders only have one routing position and each position has an entire duration of 6 hrs.

The result of an APS forward scheduling will be: Work order 1 starts at 6am, Work order 2 starts at 12pm because between 6am and 12pm the resource is not available and is occupied by work order No. 1.

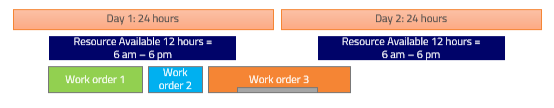

Example 2:

Work order No. 1: one routing position with a duration of 6 hours,

work order No. 2: one routing position with a duration of 3 hours and

work order No. 3: one routing position with a duration of 6 hours.

The result of an APS forward scheduling will be:

Work order No. 1 will start on day 1 at 6am,

Work order No. 2 will start on day 1 at 12pm,

Work order 3, even if you have set the same start date/time for the APS forward calculation, will be moved forward to start on day 1 at 3pm but will finish on day 2 at 9am.

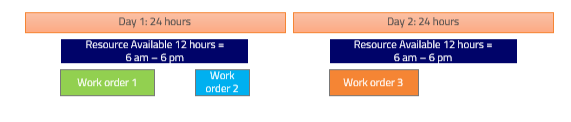

Example 3

Work order No. 1: one routing position with a duration of 6 hours,

work order No. 2: one routing position with a duration of 3 hours and

work order No. 3: one routing position with a duration of 6 hours.

ATTENTION: The following example assumes that you are working on the APS Gantt and you have set work order No. 2 manually (by dragging it on the Gantt chart) to start at a specific time (and the operation is also then fixed by APS).

In this example, Work order 3 can start only start on the second day, because between Work order 1 and Work order 2 the free time is not enough.

See Capacity planning - APS, Exploiting the full capacity