An Advanced Planning System is a software system for the configuration, planning and control of supply chains. They should enable a realistic representation of the entire supply chain from the raw material supplier to the end consumer. APS have a modular structure and are divided into three application levels which are based on each other in terms of time and logic and which differ from each other in terms of the planning horizon and the planning objects considered.

- On strategic level (configuration level, supply chain configuration), various design options in the supply chain – alternative production and warehouse locations, their capacities and the associated internal and external processes – are modeled and evaluated with regard to the associated costs and the achievable performance level.

- On tactical level (planning level, supply chain planning), rough planning for procurement, production and distribution is carried out on the basis of medium-term demand planning and sales forecasts. The aim of the planning activities is to synchronize the production and transport plans across the entire supply chain, taking into account all capacity and scheduling dependencies.

- On operational level (execution level, supply chain execution), the necessary detailed planning for the short-term coordination of quantities and capacities takes place. The functions range from sales planning to quantity, schedule and capacity planning and the resulting procurement planning to distribution and transport planning throughout the entire supply chain. Planning and optimization are based on simulations of various alternatives with regard to feasibility, costs and delivery times.

Software systems with planning functionality for supply chain management in production and logistics systems. Advanced Planning Systems complement traditional PPS systems. In addition to the usual data management, they contain modules with which truly integrated planning is possible. All available information is included in the planning. The best known representative of these software solutions is SAP's Advanced Planner and Optimizer (APO).

Core functions for operational planning is Production Planning / Detailed Scheduling (resource planning).

In Beas the APS module is available with wide functionality, and is fully integrated in every process.

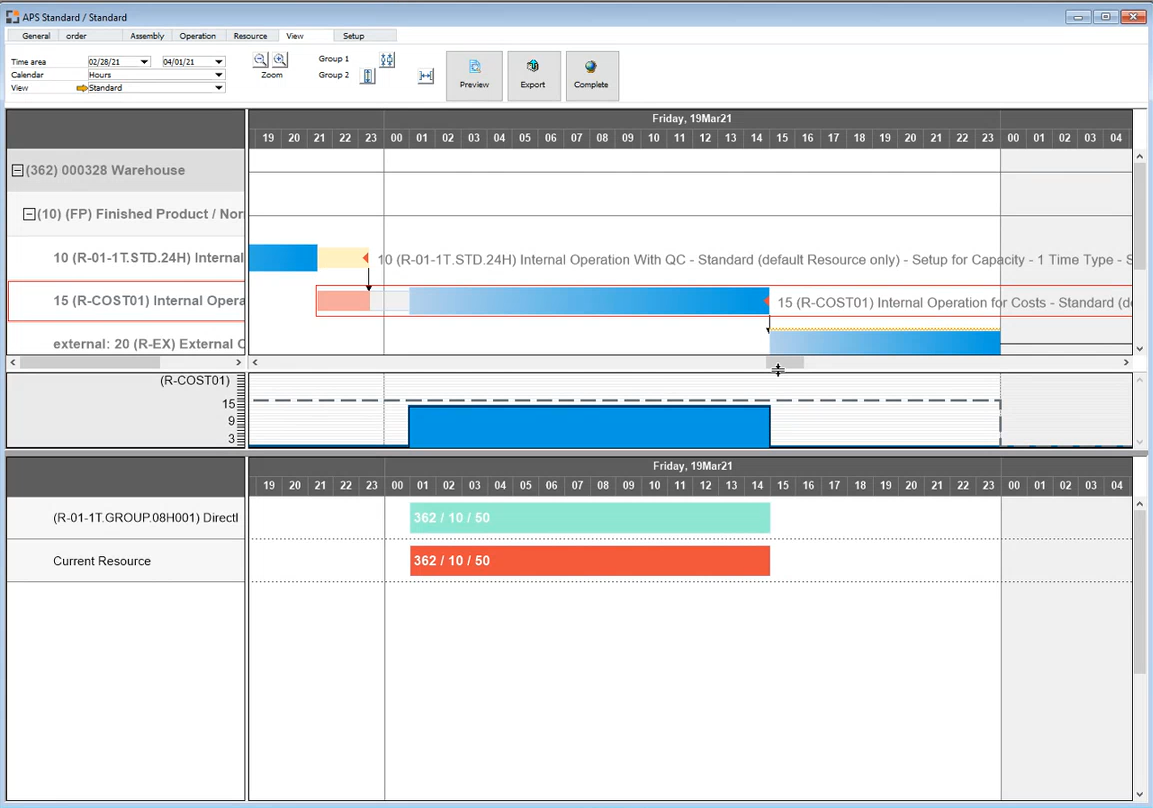

Based on the priorities, machine capacities, factory calendars and many other factors, the latest possible start date for a work order is calculated. The calculation is performed automatically. The start of the complete work order for each production item and also for each individual operation is determined. All types of resources can be reserved and the utilization can be represented graphically.

APS tools are not bound to strict mathematical rules like traditional planning and scheduling methods. Therefore, APS is rather a tradeoff between many factors to find the best solution.

In this sense, the APS system enables planners to automate, optimize, and compare production plans and schedules that reflect actual resource capacity and material availability. It synchronizes processes across plants and work centers to accurately manage labor and inventory, and meet delivery dates and increase profitability.

The simple backward scheduling method dispatches work orders only on the basis of the factory calendar and does not check the resource limits, and whether another work order has been dispatched for the same day. Therefore, without an automatic consideration of these factors, overloads can occur. To avoid this, the APS must be used, which can take into account existing time reservations, as well. The material availability can provide additional checks, so that the associated operation is started first when material is available.

The capacity calculation is a core function that is used to the same extent for rough planning, MRP run, schedule specification and APS. Any methods can be set for APS in Calculation Methods . The standard package includes Default Calculation Methods which can then be used in APS planning

Pool control uses the result of capacity planning and informs the employee in the shop about the operations that must be completed. For more general information, see Pool Control. Pool control is automatically updated and can be recalculated using Pooling/Scheduling.

Overview of functions

•Order-oriented view

•Resource or operation oriented view

•Planning at production order level or operation level

•Consideration of data from Beas work orders

•Scheduling and optimization of manufacturing processes

•Flexible calculation methods

•Flexible views and groupings

The heart of APS – capacity planning – is used by the standard program (backward scheduling) as well as by MRP, Pool Administration and all other relevant program components equally.

A change in the APS has a direct effect on production order management and pool management and also directly on MRP. All information is always available online. The information from FDC and MDE is available directly in the APS. Both rough and detailed planning is possible. Once a work order is roughly scheduled by Beas, that means if a work order BOM and routings are available, the processing can be done with APS.

The orientation is user-definable; it can be resource-oriented, order-oriented, project-oriented or by employee, material, production line, location-specifically or separately for detailed machine planning or the management of laborers. There is choice for rough planning on production order level or detailed planning as far as individual machine planning is accurate to the minute. The APS supports any priority control including user-definable nesting, tool management, user-definable multi-machine and multi-order operation, parallel processing and overlaps. Material requirements planning works directly with APS. APS is preconfigured for rapid familiarization.

![]()

![]() Youtube APS Webinar 2016 Part 1, Part 2, Part 3

Youtube APS Webinar 2016 Part 1, Part 2, Part 3

![]() How we create APS Concepts. Webinar from 10/2017

How we create APS Concepts. Webinar from 10/2017

![]() Tips and tricks (sorting, filter, task descriptions) 10/2017

Tips and tricks (sorting, filter, task descriptions) 10/2017

Pool control