|

By using overlap settings, you can define the delay for the subsequent work sequence or define to start it in parallel.

Unlike parallel resources, the subsequent work sequence can be moved freely.

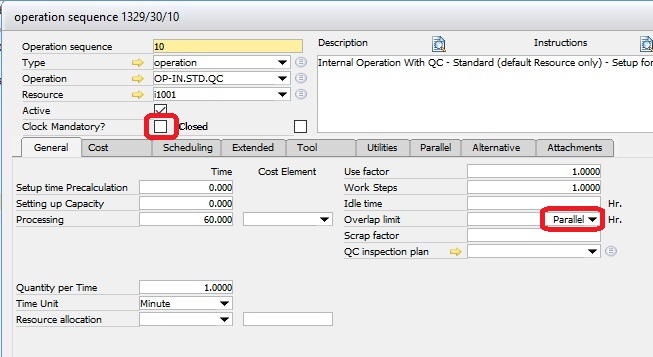

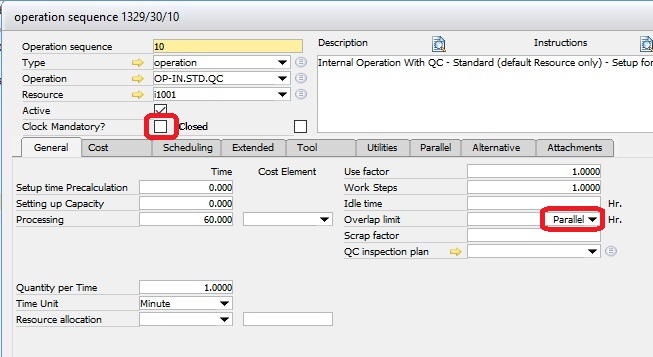

You can define the overlap limit in Routing position > Overlap limit.

Choose "Parallel", "No" or insert the number of hours/minutes manually.

If this is defined in Position 10, the next position will be parallel.

This means: "Clocking mandatory" must be disabled, because you can start with Position 20 before closing Position 10.

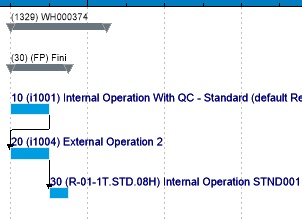

Window fert_arbplanos_edit.psr

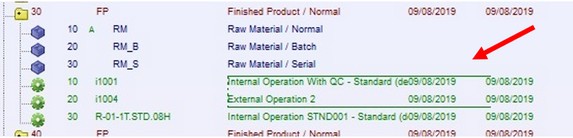

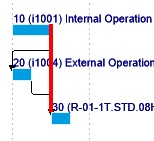

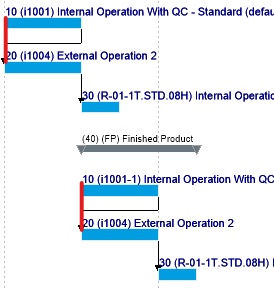

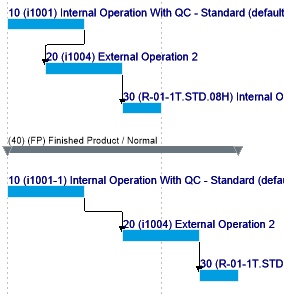

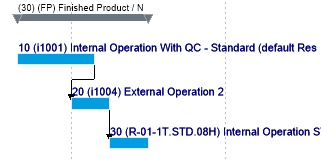

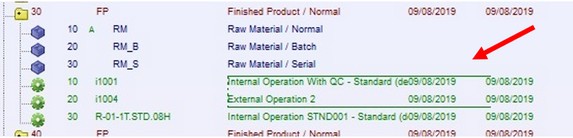

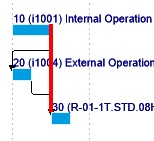

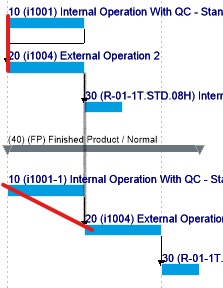

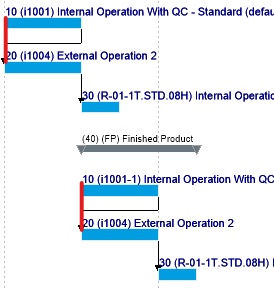

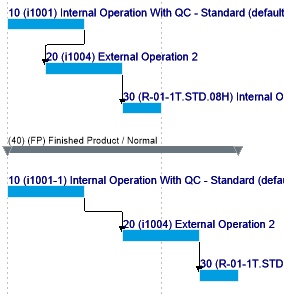

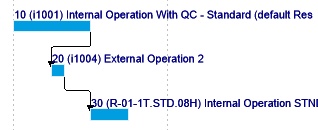

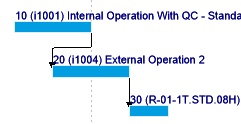

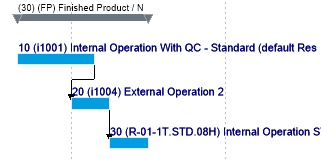

In Item Structure view you can see parallel / overlap limit information in this way:

In this example in Position 10 the "Overlap limit" is defined:

Note:

Overlap calculation runs correctly only with forward calculation.

|

|

|

0

|

No overlap.

|

Parallel

|

The earliest start date of the following operation can be the same as the first one or the next possible start.

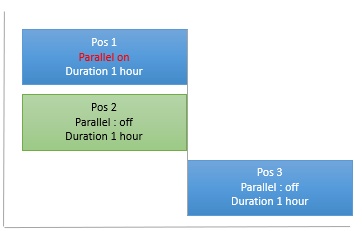

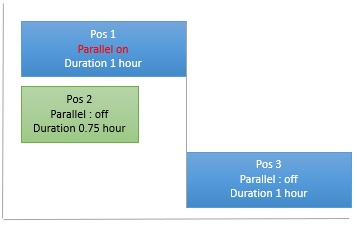

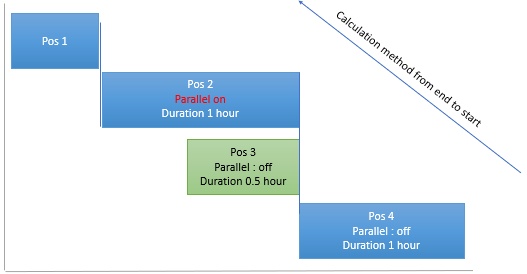

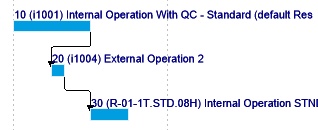

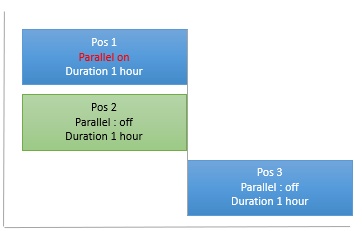

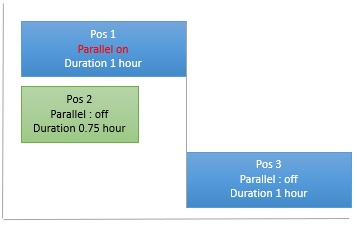

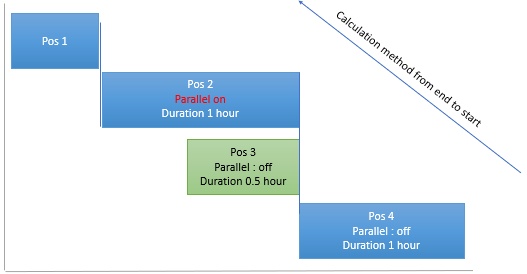

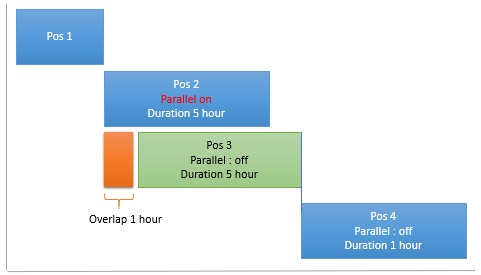

Example 1 :

Pos 1 is defined as parallel, so Pos 2 can start parallel to Pos 1

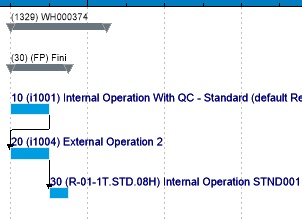

View in Beas

Start of 3. routing position is after the end of the latest parallel routing position.

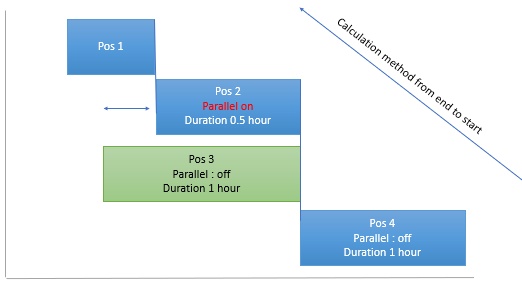

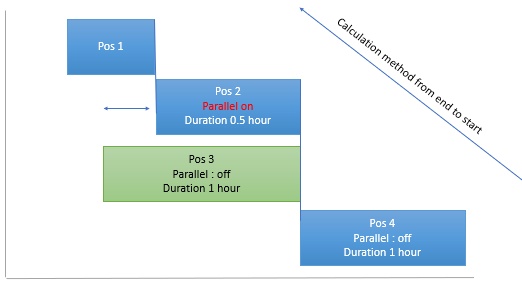

Example 2:

Pos 2 needs less time than Pos 1.

View in Beas

Start of next routing position is always after the end of the latest parallel routing position.

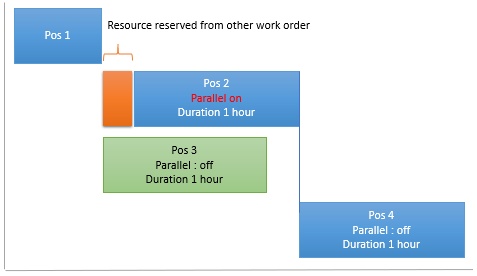

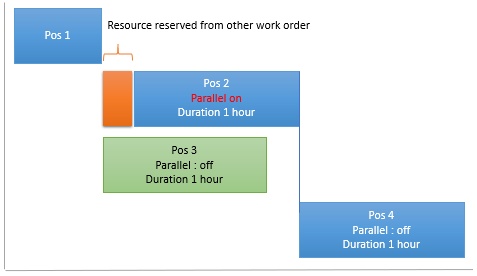

Example 3:

Scenario: Position 3 is parallel to Position 2, but after Position1 finishes, resource for Pos 2 is not available.

For example Resource is reserved by another work order.

If the resource is not available immediately, the routing position starts at the next available time.

In this example, the position 3 can start BEFORE the first position:

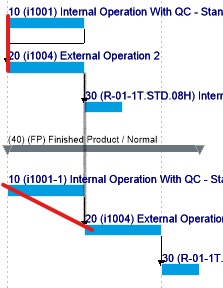

Example 4:

Scenario: 2 work order positions. Both WOs have defined the 2. operation as parallel. Start date is same.

First operation has different resource, but the second parallel operation has same resource for both WOs.

Explanation: The parallel resource uses the start date, on which the resource is free. For the first WO this is the time when operation 1 starts.

In the second work order position you see that the start date of second operation does not start together with the first operation.

The reason is that WO 1 already occupies the resource. So the second operation of WO can only start after the operation 2 of WO 1 stopped.

In that case the the second operation does not start parallel but delayed:

You can set parallel-defined operations to always run in parallel in the Configuration wizard.

Result with setting "Overlap limit = fix"

Start date of Pos 40 on Resource i1001-1 start later, because the next resource i1004 is not available before.

See  APS fix parallel routing positions APS fix parallel routing positions

|

The backward calculation cannot calculate the correct start date. It is only capable of calculating the duration.

Parallel resource: The system calculates the following:

If duration of Pos 2 is less than that of Pos 3, then Pos 1 ends with the start of Pos 2.

In this case the system is working different from forward calculation.

If you work with backward calculation, the first parallel position must have the longest duration.

|

Parallel resource:

- is always parallel - 100 %

- Parallel resource have always same start / end time

- Use Parallel resource, if you don't need this resource 100%

(Example: A worker is the "parallel resource", but is working on 4 machines in parallel. In this case he must invest only 25% for his time for this operation)

Parallel Operation:

- is not always parallel. Only if the resource of parallel operation is available

- can have different work time

- can work with resource optimization

- can have own parallel resource, tools and so on

|

|

|

> 0

Overlapping

|

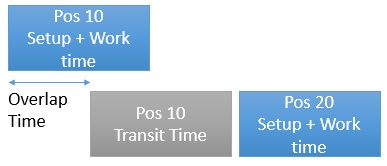

The Overlap time define, when the next operation can be started. The time, which you define, is the delay in hours/minutes, until the

next operation starts.

The defined time is the earliest time.

Example:

2 hours means, the next operation can start

- 2 hours after start current operation or after end of this current operation (if the current operation is less than 2 hours)

- if resource of next operation is not available after 2 hours, then at the time, when the resource is available.

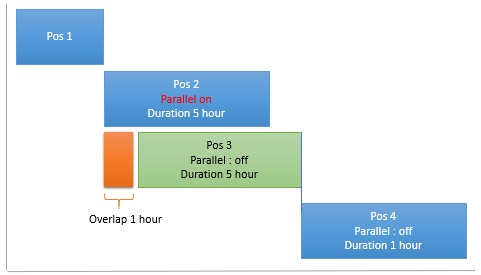

Example:

In this scenario the start date of the third routing position is the real start date of the second routing position + defined overlapping time in hours,

here 1 hour.

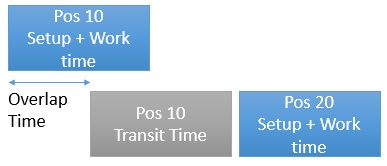

An overlap is specified in hours – based on a 24-hour day. The specified overlap always applies to the following routing position.

The overlap time is not bound to a resource calendar. This is purely hour-based time excluding time reservations or other factors.

The overlap time begins AFTER the transit time. The next routing position cannot possess a transfer time, otherwise it will be appended to the transfer time.

Example:

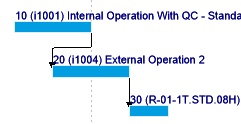

Scenario: 2 Work orders, same routing plan. In first operation different resources. Overlap limit = 0.5 hours

First work order: Position 20 start 0.5 hours after start of position 10

Second work order: Position 20 start later, because the time is reserved from first work order

If you want, that the overlap have always exact the same overlap time, a setting is available. See Configuration wizard

Example:

Scenario: Work time of second work order position is less than the work time of the first operation.

In the first operation, overlap time is defined:

In this case you're ready with second routing position before you're ready with first routing position. But you can start with third routing position only, if all parallel / overlapped routing positions are done. In this case after end of Routing position 10.

|

In a simple example the result of backward calculation is same as forward calculation

Example: Work time 1 hour, overlap 0.5 hour in first operation

But is the duration of second operation is not same as first operation, then the result is different to forward calculation:

The system calculate backward: First 30, then 20 - from 20 the overlap is calculated (Start time from Operation 20 + Overlap time from Operation 10 = End time from Operation 10.

Alternative for backward calculation is "forward late as possible"

Note:

The backward calculation cannot calculate the correct start date. It is only capable of calculating the duration.

|

|

|

Note:

The last operation corresponds to the last "reportable operation".

If an overlap is also configured in the last operation, Beas does not recognize this as the last operation.

However, the automatic assembly receipt or adjustment of the backflushed material depends on this.

Overlapping using assemblies

Assemblies can also overlap in an order-related structure.

Example:

|- Main assembly -|

|--- Subassembly -|

Start date of the main group is normally the end date of the last routing position of the subassembly. If this last routing position has an overlap, this is also considered.

Important: If an overlap is entered in the last routing position, it is no longer recognized as the "last routing position" in the backflushed posting transactions.

Help URL: https://help.beascloud.com/beas202102/index.html?parallelarbeitsgaenge_und_uebe.htm

|