For certain manufacturers, tracing each material serial or batch number from the moment it is received in the warehouse is an essential requirement for offering a full service to customers.

Beas covers this requirement with the batch number tracing and serial numbers tracing functionality that can track each single transaction on a serial or batch number.

The default name of this field is Batch number. However, if a serial number is entered in the field, the name of the field will be displayed as Serial number.

Using batch and serial tracing you can determine the following:

| • | Which batch or serial number was built in to which batch or serial number |

| • | Which batch or serial number a batch was built into or transformed to |

| • | Whether a batch or serial number was checked against a QC-order |

| • | Whether a production time receipt was reported for an operation linked to a batch or serial number |

| • | Any resource(s) related to an operation which is linked to a batch or serial number |

| • | The delivery note that was created for the delivery of a finished batch or serial number item |

The following transactions are considered for batch and serial number tracing:

| • | Production receipts and issues |

| • | Production backflushing booking processes |

| • | Batch transfer |

| • | Split batch |

A direct batch tracing can only be completed, if the receipt and issue are in a process. This is done for example, at backflushing WO or at a order time receipt - last operation sequence.

Only an indirect assignment is possible if the issue process is separated (Area=indirect). In this case it can only be determined which batches have been used or created for the work order position.

No batch and serial number tracing is available for other types of transactions, for example SAP Business One - Production. The connected transaction is only displayed in the Documents area.

Example:

Assembly A, batch A1 contains assembly B

Assembly B has been created with batch B1 and receives material C

Material C has been booked with batch C1

The following can be seen in the structure display:

A1 (A)

|- B1 (B)

| |- C1 (C)

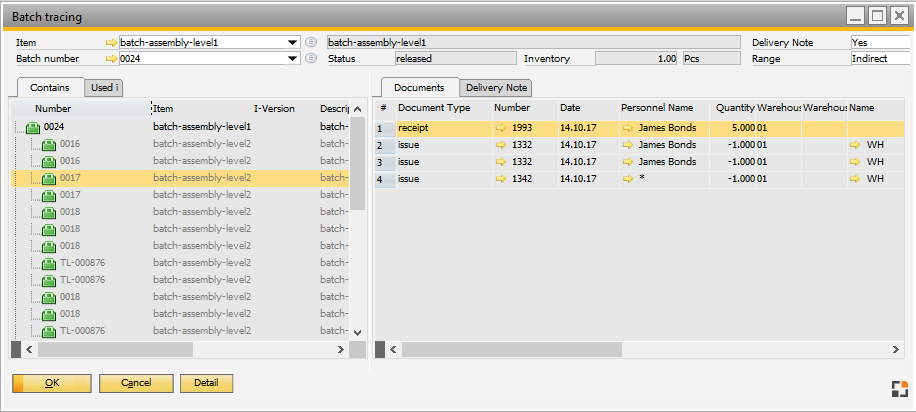

The batch window

PATH: Inventory > Item management > batches > batch tracing.

Window mw_tracing_master.psr

Area |

Description |

||||||||||||||

Header: Item / Batch |

Enter the item batch or item serial number.

Delivery Notes: Specifies whether delivery note information is displayed related to the selected batch or serial number.

Range: Specifies the range of items and transactions that are be displayed for the specified item.

|

||||||||||||||

Contains tab |

|

||||||||||||||

Used in tab |

Displays all batches or serial numbers that the searched batch or serial number was used in. |

||||||||||||||

Documents tab |

All transactions and QC-orders are displayed here for the batch or serial number selected in the structure area. Beas document types like batch transfer or batch split are taken into account. The screen can be configured with Window settings. |

||||||||||||||

Delivery Note tab |

Delivery notes that the batch or serial number was delivered are displayed in this area. This area shows delivery notes related to all displayed batches. |

Field |

Description |

Document |

Document number. |

Type |

Document type. |

Date |

Document date. |

Personnel |

Personnel who created the document. Important: The employee name is displayed, not the user name. No name is displayed, if working without a terminal, if there is no connection between user name and employee name, or the document was not created in Beas. |

Quantity |

Posted quantity. |

Warehouse |

Affected warehouse. In case of transfer, the withdrawal warehouse is displayed. |

Warehouse 2 |

In case of a transfer, the target warehouse is displayed. |

Name |

Customer name. |

Order, Pos 1, Pos 2 |

Linked work order document: order number, assembly position, BOM position |

QC-order |

Linked QC-order. |

Time receipt |

Linked time receipt. Important: This is only displayed for posting documents, created from beas9.0-000 Patch3 and only, if the posting is made together with a time receipt. |

Resource |

Reported resource in the linked order time receipt. |

Reference |

Reference number of posting document. |

Information |

Information, Memo from linked document. |

Work station |

The work station, where the document was created. Only displayed, if the document was created by Beas. |

Beas version |

The version of Beas that the document was created with. |

If response times are long, adjust the following settings:

|

(beas 9.1 PL: 08)

Beas offers an object, that processes the structure report in the BEAS_REPORTAUSWERTUNG table. A structure report and batch tracing report cannot be created with SQL statements.

Execute the following script commands before the output of the report: object=ue_chargenbuchung=tracerreport=<itemcode>=<distnumber> [=<sysnumber> [=Bereich]] or for the opposite - used in object=ue_chargenbuchung=tracerreport_buildin=<itemcode>=<distnumber> [=<sysnumber> [=Bereich]] Return = Variable id

If you do not indicate the sysnumber, it is determined automatically, as long as it is a batch. Serial numbers must be entered.

Area: all = all connections bfa = directe and indirect connections (very slow)

via select * from "BEAS_REPORTAUSWERTUNG" where "ID"=<id> order by "NR" The report is generated. After this, the content should be deleted again. delete from "BEAS_REPORTAUSWERTUNG" where "ID"=<id>

The following fields are available in the BEAS_REPORTAUSWERTUNG table:

|

Window: mw_tracing_master

beas Version 9.0-000-003-013

see