|

Factory Data Capture (FDC) is a functionality to register production time and quantities.

PATH: Administration > System Initialization > Configuration wizard > Production.

Notes on order time receipt

If working with attendance, set the option "Time linking" to "Shift definition + Attendance". In this case, the employee does not have to logoff from his ongoing work orders when he leaves.

|

|

|

Time Linking

|

Depending on settings, the duration is computed when a Time receipt is created.

|

|

|

none

|

The total time of order logon and order logoff is taken. Breaks or attendance times are not considered.

|

Shift definition

|

The Shift definition stored in Personnel master is taken into account, including breaks. Rounding rules are not considered.

Example:

Shift definition 7:00–17:00, Break from 12:00–13:00.

Order logon Start: 6:50, end 7:30, computed duration: 30 minutes.

Order start: 6:50, end 14:00, computed duration = 7:00–14:00 minus the break 12:00–13:00 = 6 hours.

Order start 16:00 yesterday, end today 10:00.

Computed: 16:00–17:00 and 7:00–10:00 = 4 hours.

|

Shift definition + Attendance

|

Next to Shift definition, stored in Personnel master the actual attendance is considered. Computing order time, the rounding rules stored in period rule are considered under certain conditions.

Note: The attendances can only be considered if the capture is done via the BEAS system. Attendances which were imported via Integration HUB will not be considered at the time accounting of the order time.

Example:

Shift definition 7:00-17:00, break 12:00-13:00.

Attendance: Arrival 6:50, Break from 8:00–9:00.

Logon work order 6:55, logoff work order 14:00.

Computed duration:

7:00–8:00 = 1 hr. , after the employee was absent.

9:00–12:00 = 3 hrs, followed by lunch break.

13:00 –14:00 = 1 hr.

Total: 5 hours.

For open attendance time (if not yet left) rounding rules are not taken into account at work order logoff.

Example:

Rounding rule 30 minutes.

Order time receipt 15:00–15:45.

Computed 15:00–15:45 = 45 minutes.

Note for setting up rounding rules:

If the employee leaves differences may occur, as according to the rules, attendance ends at 15:30.

When computing the start time, the rounding rule is considered only if this is the first logon of the day.

Example:

First arrival 07:05, work order logon 7:19. Computed from 7:30.

Arrival 7:05, Leaving 8:00, arrival 8:25, order logon 8:27. Computed from 8:27.

|

Note:

Settings on parallel computation are taken into account for all combinations.

See Order time receipt, Shift definition; App Arriving /Leaving

|

|

Attendance linking

|

If active, the employee logs on automatically in attendance when registering to the first work order. He can also log off from attendance when creating a time receipt.

Note:

This option links the attendance to an order time. This means that only those order times are considered when the employee was on duty.

If you want to link the order times to attendance, use setting "Time-linkage" – "Shift definition + Attendance".

This setting refers to the function Terminal – logon order and logoff work order.

App "logon work order": The employee is logged on automatically in attendance, if he was not before. If the attendance logon is not possible, the work order cannot be started.

App "logoff work order": A checkbox "logoff from attendance" is displayed. If it is disabled, after logging off from the work order the employee is logged off from attendance automatically (in case he was logged on.)

|

Variable: timebdekop, 1=on, 2=off

|

|

Parallel calculation

|

If this option is activated (default), the work order times which have been reported parallel are split appropriately. If this is deactivated, each report gets the total time.

Example 1:

Logon working sequence A+B at 11 o'clock, logoff at 12 o'clock = total 1 hour

Because they run parallel, only the half is assigned (that is 30 minutes) to each working sequence.

Example 2:

Logon working sequence A+B at 11 o'clock, logoff at 12 o'clock and B at 1 p.m.

Each working sequence gets 30 minutes between 11–12 o'clock, from 12 o'clock to sequence B are assigned 60 minutes. As a result, working sequence A gets 30 minutes and B gets 90 minutes.

If the option is deactivated, the behavior changes. In example 1: A and B each get 60 minutes, in example 2: A = 60 minutes, B = 120 minutes.

Important: automatic distribution of reported times to resources does not work at quick input in lists. For time receipts the terminal needs to be used.

At parallel calculation for master-slave operations only the master operations are taken into account, because the part times are distributed to the slaves operations.

|

|

|

Allow closing of operation sequence ?

|

If yes, the employee can close a work order via a terminal – even if there are quantity shortfalls.

|

Close operation sequence automatically

|

If activated

the system always closes the routing position automatically if the total time receipt quantity + scrap quantity >= planned quantity

If you clock in time receipt window on "F2 Partial complete", the system ignores this, if this setting is activated.

The system does not close automatically if a user is working on this routing position.

if not activated

The System only closes the routing position:

- if you close this manually

- if you click in time receipt window on F3 completion confirmation

See Production time Receipt - Partial complete

|

|

Security query at last working position

|

Activate security query if last operation has been received and assembly is posted in.

See Report production times

|

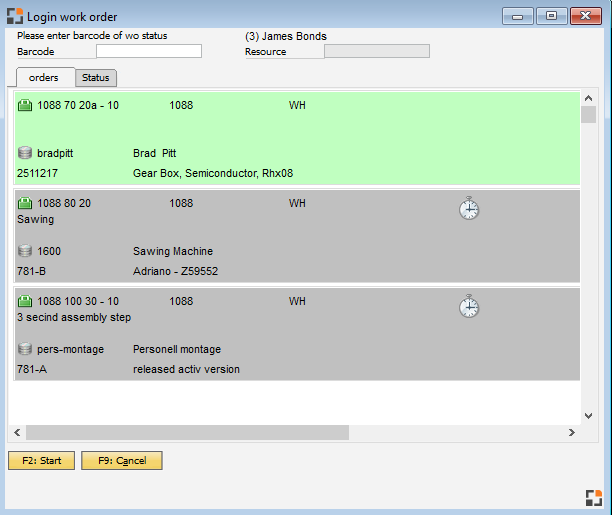

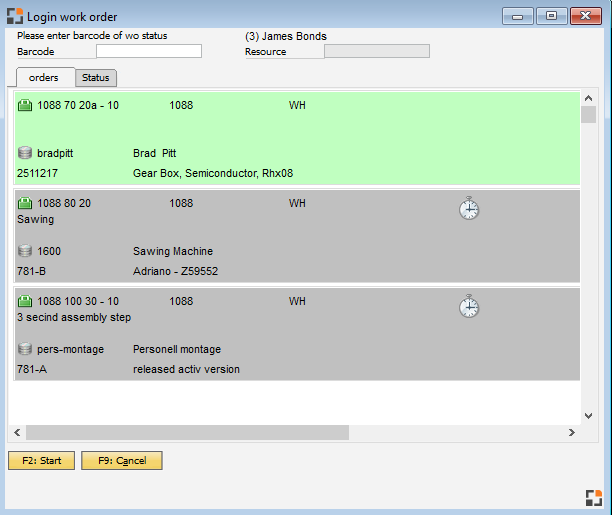

Login to work order: multiple logon

|

This setting relates to the window Login Work Order

(not WEB-App)

Instead of closing the window at a order logon, the window returns back to the operation sequence selection and the next operation sequence can be selected directly if this option is active.

|

|

Time distribution Master-Slave

|

Percentage of default time (default setting): The complete time is distributed on operations. Each operation receives a percentage part of the default time.

Example: Slave Pos 10 60 Minutes.

Slave Pos 20 120 Minutes.

Master Pos 30 20 Minutes.

perceptual ratio : Pos 10 30% ; Pos 20 60%; Pos 30 10%.

Note:

For calculating the planned time the reported quantity is used as reference. For this reason, a quantity needs to be entered.

With time receipts for Pos 30 (Master-operation) of 10 minutes 2 time receipts are created.

Pos 10 30% of 10 Minutes = 3 Minutes.

Pos 20 60% of 10 Minutes = 6 Minutes.

Pos 30 10% of 10 Minutes = 1 Minute.

Total = 10 Minutes.

Note:

To work properly, this function requires a plan time and posted quantities.

With plan time 0 or without a quantity you will get incorrect results.

If no quantity was reported, the new reported quantity is posted to the master only. If a quantity had been posted before, the result will be a percentage of 0, thus no distribution.

|

Each operation gets the same time. Default time is not considered.

In the upper example with time receipt on Pos 30 with 10 Minute1, the following time receipts would be created.

Pos 10 10 Minutes; Pos 20 10 Minutes; Pos 30 10 Minutes.

Total: 30 Minutes. This concept is used in production lines.

|

Reported time for master operation, planned time for slave operation. Planned time is calculated: ((job time * planned quantity)+setup time) / planned quantity * reported quantity.

|

The smallest unit of a time receipt is the minute. Due to conversion rounding differences may occur. Parallel operations are not considered for slave operations.

|

Setup-Variable: timemasterslave P=percentual default time, E=no distribution

|

|

Master-Slave not at Manual Message

|

If for a slave-operation a time receipt was created, a second time reporting can be blocked by the Master, by enabling this option.

Example with enabled option:

Operation 10 = Master.

Operation 20 = Slave.

a) Reporting for 10: time receipt created for 10 and 20.

b) Reporting for 20: time receipt created for 20.

c) Reporting for 10: time receipt created only for 10, as there was already a manually reporting for 20.

With disabled option, for c) time receipts would be created for both 10 and 20.

Default: Option disabled.

setup-Variable: masterslaveman J/N

beas9.0-004-000-000

|

|

Order time receipt: Protocol

|

If enabled, at new creation, change or deletion (in this case a cancellation) a protocol is always created, even if there are no costs to be booked.

|

Material tracing based on operation

|

Material entries are mapped to the position currently registered.

This option also allows material tracing for partial notifications. For this purpose a temporary batch is created for each partial receipt to which the material is linked.

Attention:

This function requires an extended terminal, which must be customized. Please activate this option only if the according extensions have been installed and the concept has been developed completely.

This option is only available in expert mode.

Further effects:

If a value > 0 is entered in the operation and the use factor and a batch number is entered in the order time receipt, the order time receipt is split.

Example:

Use factor = 10.

Order time receipt = Quantity 5, time 10.

10 order time receipts are created each with 0.5 pieces each and a time of 1.

setup-variable ftaplcharge j/n

|

|

Preliminary test entry in journal

|

Creating a time receipt, a journal entry is created in the background by beas using the SAP DI-API. Several problems may occur here. For example: blocked number range, no authorization, network overload, etc.

In protocol, errors such as "DI API of_getbusinessobject 30: Error calling external object function getbusinessobject" are logged. These errors require a manual correction.

With this option, a journal entry is simulated in advance. If no posting is possible, also no work order time is registered. This reduces the risk of differences in financial accounting significantly.

If the option is enabled, an account must be specified to which a test booking should be done.

Note: By executing test postings, the network and the overall system is more stressed. In case of an "overload", proper measures must be taken.

|

|

Cost center determine by

|

Define default cost center for time receipts.

Beas uses this in the time receipt view as default.

Assembly/Material: Determination via item from "Profit center“ field.

Personnel: Determination at time receipt via employee record.

|

|

Help URL: https://help.beascloud.com/beas202102/index.html?bde3.htm

|