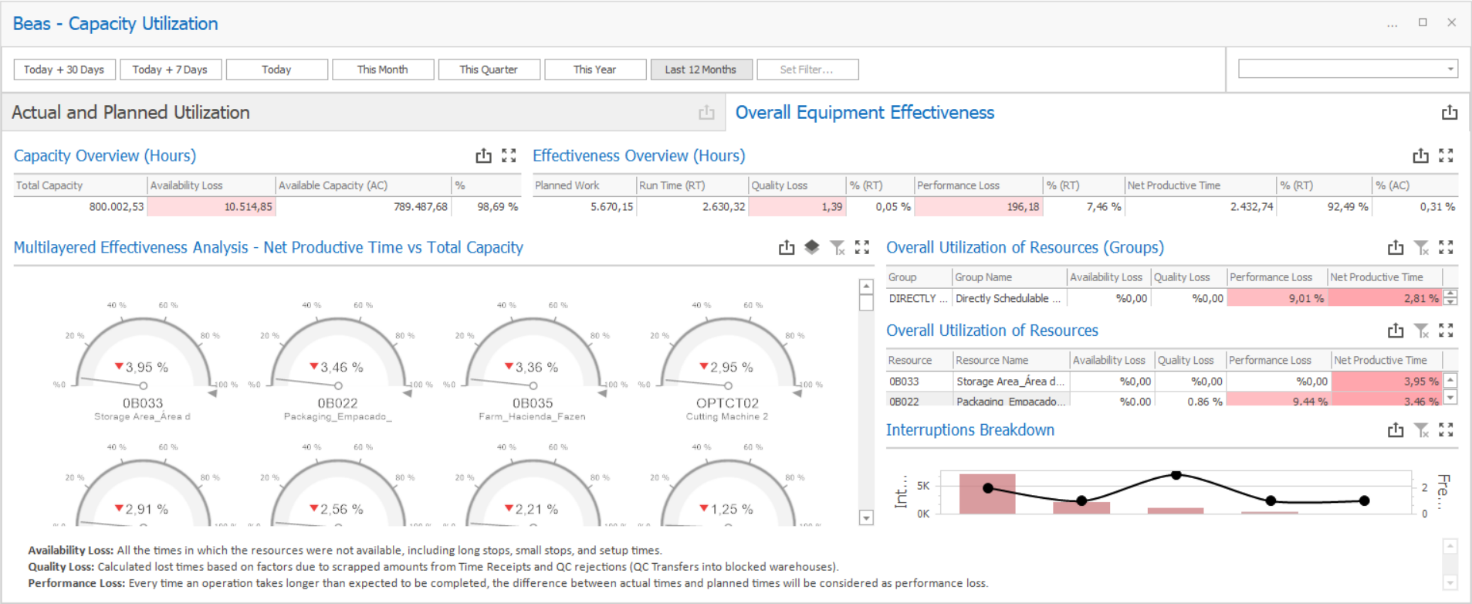

The Overall Equipment Effectiveness, or OEE, is a gold standard KPI for measuring manufacturing productivity, clearly indicating how effective the different resources are. The calculation of the OEE considers three losses to calculate effectiveness:

a)Availability Loss: All the times in which the resources were not available, including long stops, small stops, and setup times. The availability loss is used to calculate the Available Capacity (AC), by discounting it from the Total Capacity;

b)Quality Loss: Calculated lost times based on factors due to scrapped amounts from Time Receipts and QC rejections (QC Transfers into blocked warehouses). The quality loss is used, in combination to the performance loss, to calculate the Net Productive Time, by discounting it from the Run Time (RT);

c)Performance Loss: Every time an operation takes longer than expected to be completed, the difference between actual times and planned times will be considered as performance loss. The performance loss is used, in combination to the quality loss, to calculate the Net Productive Time, by discounting it from the Run Time (RT).

The Overall Equipment Effectiveness tab will interact with the Actual and Planned Utilization tab, meaning that any filters or selections applied on Overall Equipment Effectiveness will also filter the data under Actual and Planned Utilization tab.

Dashboard sections:

Effectiveness Overview (Hours)

Multi-layered Effectiveness Analysis

Overall Utilization of Resources (Groups)

Overall Utilization of Resources