Operation catalog - Routing - Production routing - Calculation

In this tab you can define alternative resources related to a routing position.

In APS and Work order you can change the alternative resource with one mouse-click.

The alternative resource can have its own parameters as setup time, processing time etc.

The option "Optimization"checks whether a faster production would be possible using this alternative resource.

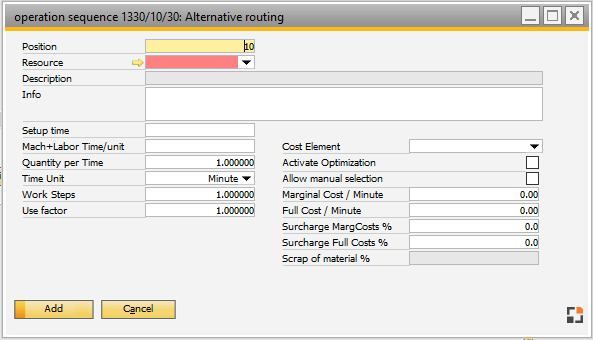

The user can insert, edit and delete resources. To assign an Alternative resource, click on Add, and a new window opens:

fert_arbplanpos_edit_alternativ_edit, artikel_arbplanpos_edit_alternativ_edit, stamm_ag_alternativ_parallel_edit

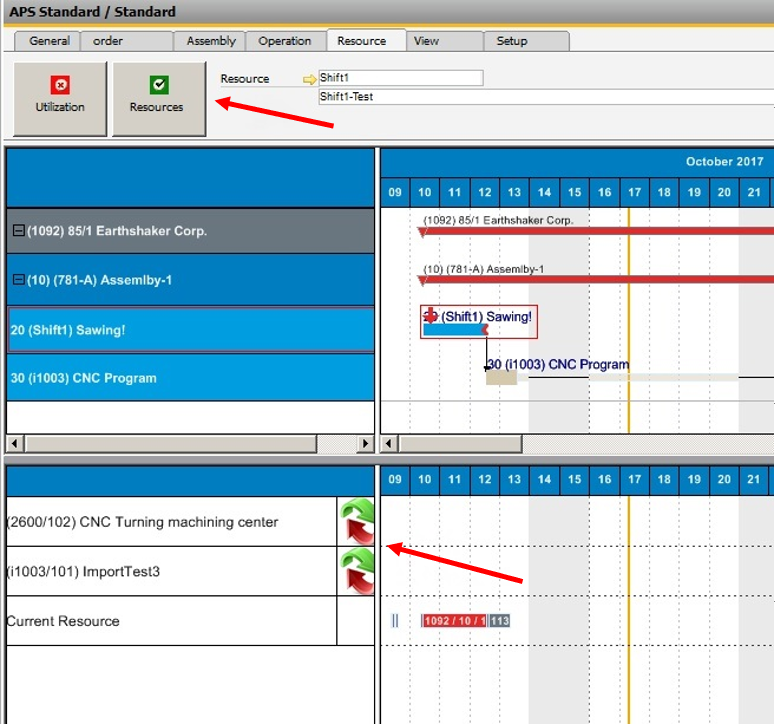

Selection in the APS view:

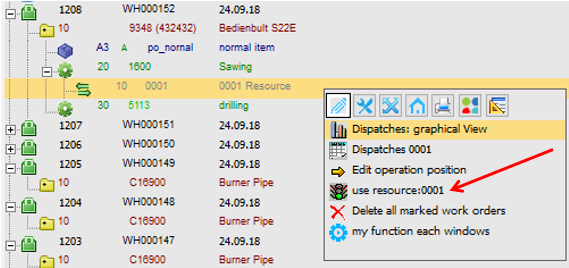

View in the production structure:

|

See Overview alternative resources

The alternative resource can be selected manually in the APS – graphic view and Production structure display.

Note: Alternative resources are not supported in the Precalculation.

Field |

Description |

Position |

Used for sorting the parallel resource list from the routing. It is a consecutive number, but not a primary key. |

Resource |

Select the resource ID of the parallel resource from the existing resources. The alternative resource can be selected manually in the APS - graphic view and production structure display. |

Description |

Description of the resource that comes from the resource master data and cannot be changed. |

Info |

Additional free text information. |

Throughput Time area

Field |

Description |

|

Setup time |

Setup time of the alternative resource process. Default time can be specified in the Quantity per time parameter. |

|

Mach+Labor Time/unit |

The Mach+Labor time for a unit of quantity using the Time unit in Production UoM Quantity per time finished parts. Note: Alternative resources do not manage Secondary+Labor times. Therefore, if a main resource manages secondary times when switching to an alternative resource, the information of the secondary values in the operation will be lost, especially if you want to return to the main resource again. In this case you will have to add those data manually or refresh the order if applicable. |

|

Quantity per Time |

Defines the number of finished parts in Production UoM to which the processing time refers, e.g. 10 minutes per 1000 kg. See Routing position. |

|

Time Unit |

Defines whether times are specified in hours or minutes. See Routing position. |

|

Work Steps |

Number of required work steps used as a multiplication factor for the production times e.g. 10 work steps in "processing time" are required . |

|

Use factor |

Use factor to split the production time amongst more finished goods, e.g. 10 units are produced at once per step or hub and per processing time. |

|

Cost element |

Accumulated costs are written to this cost element. |

|

Activate Optimization |

If active, define whether Beas should automatically select the most adequate resource, amongst the main and alternative resources in the APS calculation. The resource is replaced automatically. |

|

Allow manual selection |

|

|

Scrap of material % |

|