In Routing position > Extended you can define the Scrap of Material related to a routing position.

Example:

You must produce and fill 6 kg of paste

15% is lost during filling

Now it must be calculated how many liters of paste are needed.

Calculation

Correct formula is: Quantity: (100 – scrap% ) * 100

If you need 6 kg of finish product, then you need

6 kg : (100 - (0.15) * 100 = 7.059 kg paste

If you see the opposite:

I fill 7.059 kg paste and lose 15% =

7.059 - (7.059 / 100 * 15) = 6 kg

In the Configuration wizard > "Behavior for Routing Scrap of Material % affect to" you can define how the program should work.

The following settings are available:

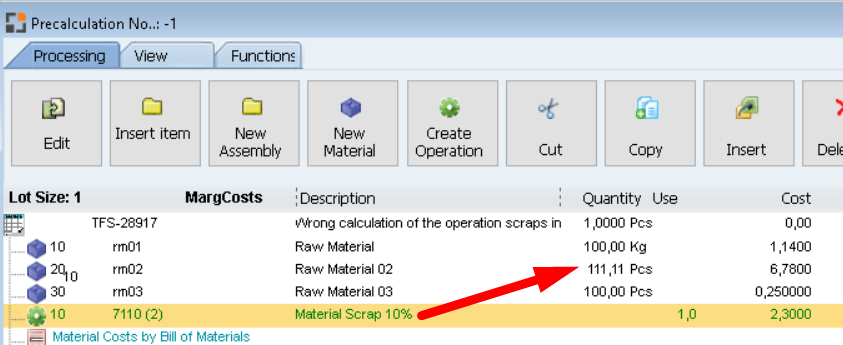

Result see this example:

|

This is the Standard setting

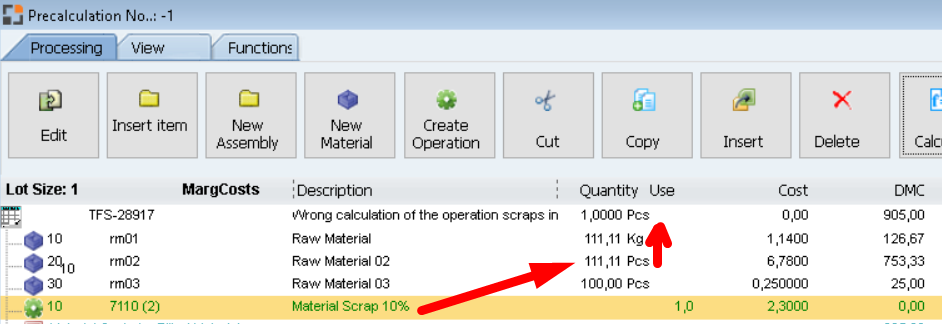

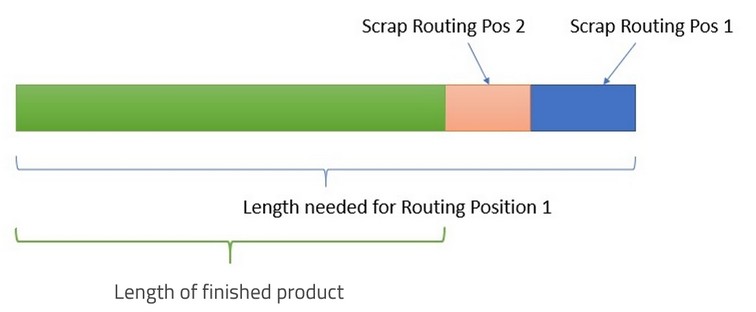

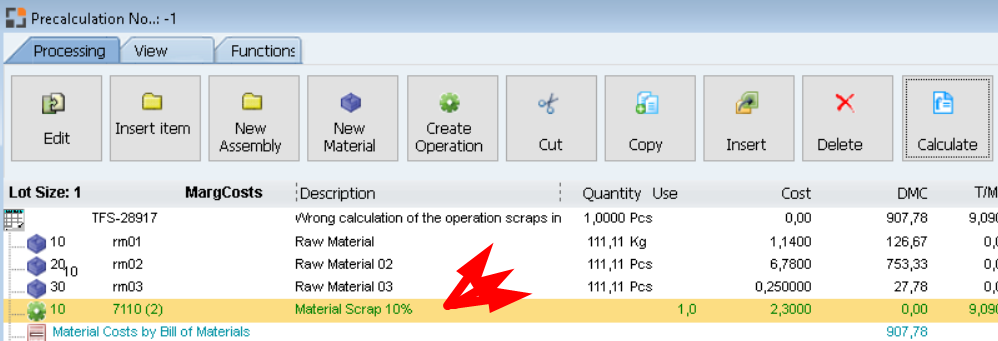

Example: When a bar is sawn, a scrap rate of 10% may be incurred. If the material is ground, the bar becomes even shorter, that is a longer length must be cut beforehand,

Example: We need a finished product with a length of 250 mm.

We start with 308.65 mm - sawn : scrap 10% = 277.78. Continue with 277.78 mm - ground : scrap 10% = 250 mm.

Calculation

Correct formula is: Quantity : (100 – scrap% ) * 100

Position 20 we need 250 : (100 – 10) * 100 = 277.78 The value is entered into the production BOM item, column "calculated scrap" as fix value.

|

|

Notes:

| • | This field is only visible, if in Configuration wizard > Master data > routing > operation related material scrap" is enabled. |

| • | The Item Report – Item Structure report does not support the Material Scrap factor on Routing Level. |

| • | Enable this option only if absolutely necessary; the computation will take considerably longer. |

| • | In work order this field is blocked, because scrap of material is determined only at the moment of creating the work order |

| • | When checking which routing positions are considered, the following criteria apply: - Validity date - Active (no formula, no quantity check) - Variants (A–Z) Not checked: - Variants formulas, Product configurations |