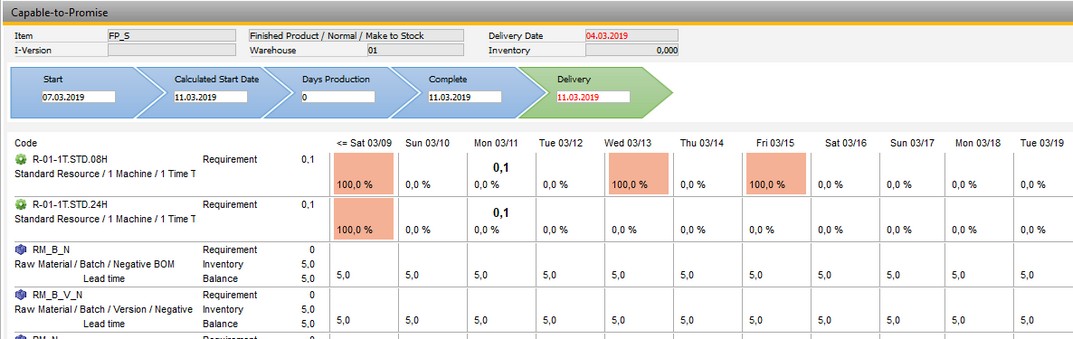

With the Capable-to-Promise, the expected delivery date can be determined based on forward resource-scheduling and consideration of existing resource reservations.

This function is only available with active APS License.

![]() What does Capable-to-Promise System (CTP System) mean?

What does Capable-to-Promise System (CTP System) mean?

A capable-to-promise (CTP) system is a system that helps companies anticipate demand and match it to their peak production and capacities. Using a CTP system allows a business to create a balance between what it can produce and what customers and clients are requesting. |

![]() The difference between Available-to-Promise (ATP) and Capable-to-Promise (CTP)

The difference between Available-to-Promise (ATP) and Capable-to-Promise (CTP)

The basic dfference between the two systems is that while ATP looks at the availability of materials, ignores time reservation, CTP assesses the extra components, considers labor availability, the capability of the business fleet and how materials work through a supply chain. To achieve this, CTP may consult several production departments for useful information to assess delivery possibilities. For details on Available-to-Promise in Beas see next chapter, ATP. |

For Configuration See Configuration Wizard > Sales.

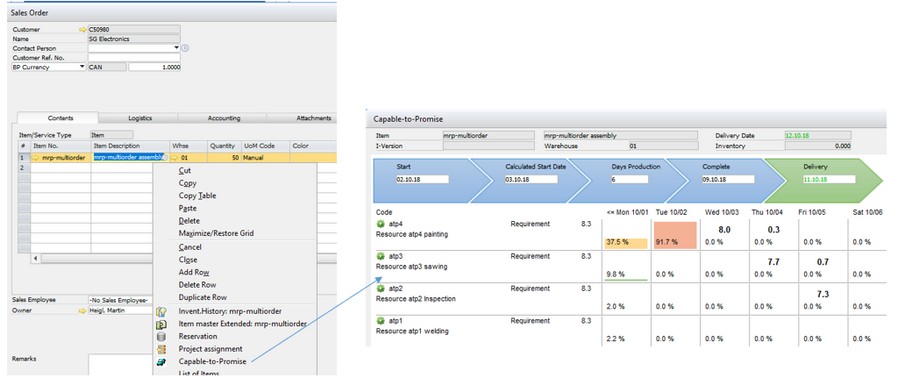

PATH: Sales – A/R > Sales Order/Sales Quotation > right-click on an item > select "Capable-to-Promise".

Window atp_view.psr

The Beas CTP:

- Creates a forward calculation for the assembly.

- Checks availability of resources and material for the complete order-related sub-structure of the assembly.

- Displays the possible delivery date.

- Displays material- and resource information needed for this assembly.

What you need for using CTP:

APS License

Correct planning data inside the system

Actual MRP

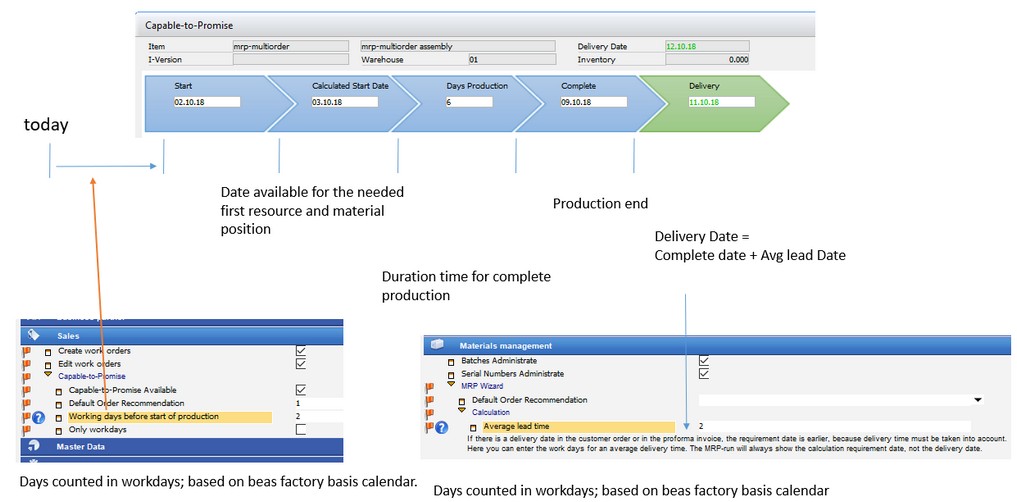

The CTP uses the Default MRP function to calculate lead time. It is a resource planning tool. The CTP cannot determine the actual delivery date. It is only an auxiliary tool for the seller. A more precise statement can be determined using the APS.

The CTP - Ignores Variants (Formulas and Scripts), Configurations and Precalculation, but supports Short Variant (A-Z) and Item Version control. - Ignores formulas inside Bill of Materials and Routing positions. - Ignores routing related Bill of Materials Positions. - Ignores resource reservation from other sales order if work order does not exist. - Material check is based on last MRP run and it does not check the actual material situation. |

Before you start:

| • | CTP can deliver correct information only if all data are correct. |

| • | Define a default MRP (see Configuration wizard) and calculate this every day. |

| • | Calculate work orders every day and use forward calculation. See APS. If resource reservations are in the past, the result cannot be correct. |

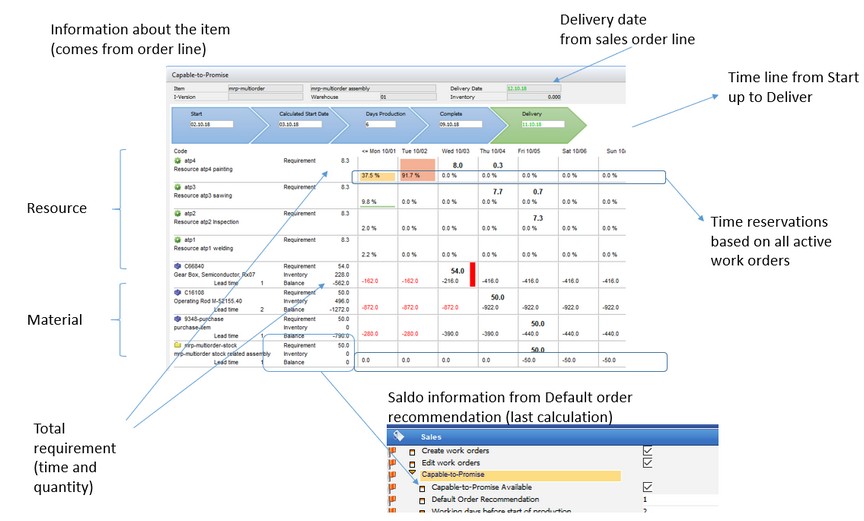

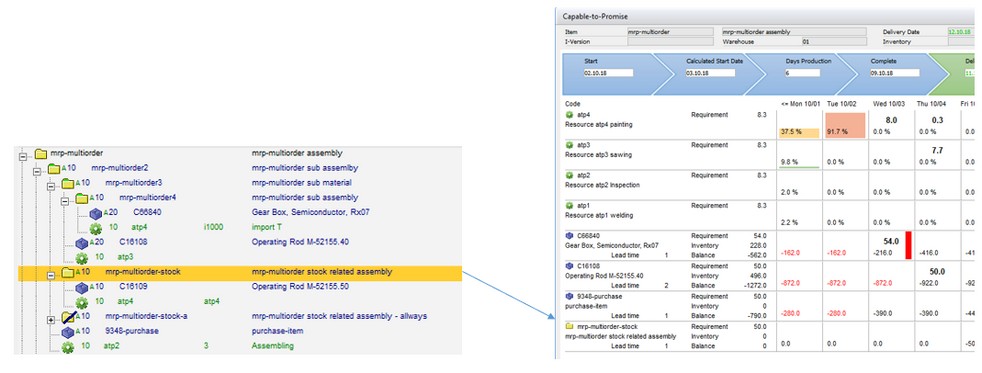

Multi-level breakdown All BOM items and routing items are taken into account. If a BOM item is order-related or "always explode" is stored there, it is exploded further. If the BOM item is a warehouse-related assembly, no further explosion takes place.

The original APS forward scheduling is used. The default is the routing. All stored rules and optimization functions are considered, including parallel tools and resources and resource optimization.

Sub-assemblies are expanded first. Only when all sub-assemblies have been completed can the assembly above them be started.

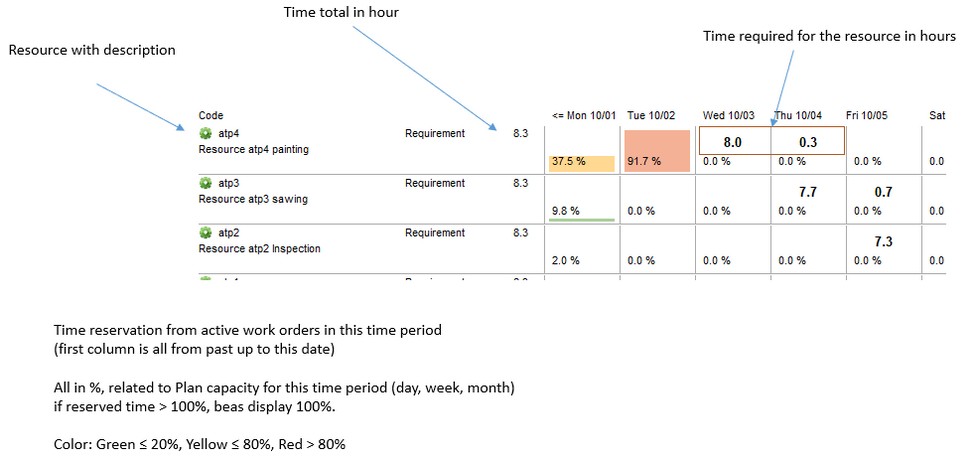

Resource View in CTP

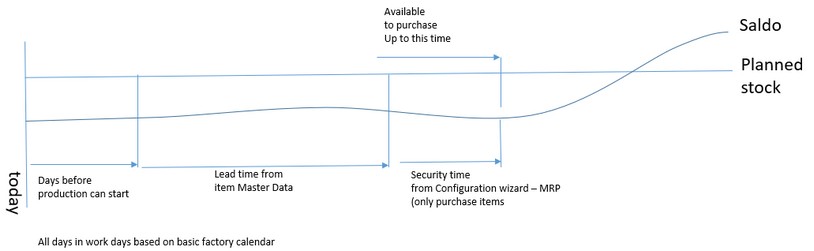

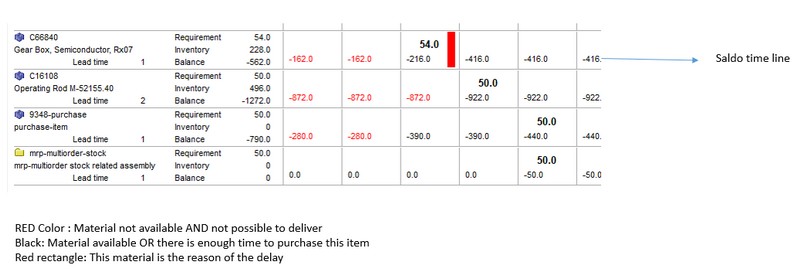

Material consideration Depending on the MRP definition, sales orders and forecasts are taken into account. You can use the same MRP as the reference that is used in the item history. If an Item (Material or stock-based assembly) is not available, the lead time stored in the item is used.

|