Beas supports two different calculation methods:

Detailed planning and Exploit Full Capacity

You can define the calculation method in

Production > Capacity Planning, APS > APS Calculation Types > Consider capacity limits

Beas applies this calculation method only if the following conditions are met:

How Detailed planning works:

The detailed planning checks to the minute when a resource is available, and whether the work sequence can be completed in the available time windows. Assumptions: our resource is the same on all routing position on the below reported examples and has a total capacity of 12 hours per day.

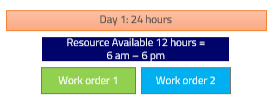

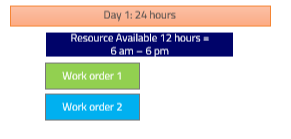

Example 1: Work order No. 1 and Work order No. 2 start at 6am on the same date/time. Both work orders only have one routing position and each position has an entire duration of 6 hrs. The result of an APS forward scheduling will be: Work order 1 starts at 6am, Work order 2 starts at 12pm because between 6am and 12pm the resource is not available and is occupied by work order No. 1.

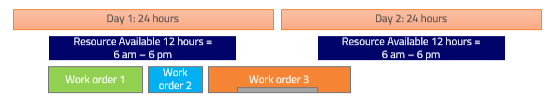

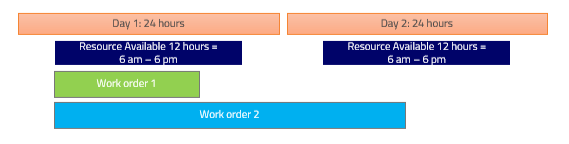

Example 2: Work order No. 1: one routing position with a duration of 6 hours, work order No. 3: one routing position with a duration of 6 hours. The result of an APS forward scheduling will be: Work order No. 1 will start on day 1 at 6am, Work order No. 2 will start on day 1 at 12pm, Work order 3, even if you have set the same start date/time for the APS forward calculation, will be moved forward to start on day 1 at 3pm but will finish on day 2 at 9am.

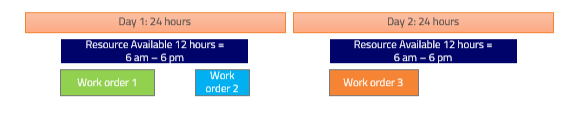

Example 3 Work order No. 1: one routing position with a duration of 6 hours, work order No. 2: one routing position with a duration of 3 hours and work order No. 3: one routing position with a duration of 6 hours.

ATTENTION: The following example assumes that you are working on the APS Gantt and you have set work order No. 2 manually (by dragging it on the Gantt chart) to start at a specific time (and the operation is also then fixed by APS). In this example, Work order 3 can start only start on the second day, because between Work order 1 and Work order 2 the free time is not enough.

See Capacity planning - APS, Exploiting the full capacity

|

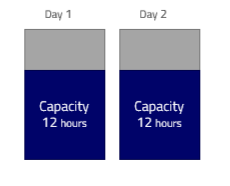

This method checks the total available capacity on a day for a resource. Note: It does NOT check when the capacity is available.

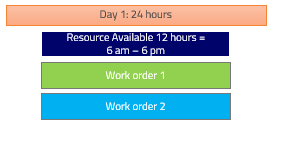

Example 1: 2 work orders, one routing position per work order, each routing position with a total duration of 6 hours. Both work orders are planned in APS with forward scheduling and with the same start date/time. The result of an APS forward scheduling will be: Both work orders will have the same start date and time because Work order 1 needs 6 hours and 6 additional hours are available for Work order 2. The start/end time of each work order is not checked by Beas.

Example 2: 2 work orders, one routing position per work order, each routing position take 8 hours. We have a total duration of 16 hours for both work orders with a total available capacity of 12 hours on the machines. The result of an APS forward scheduling will be:

Here again both work orders start at same time but the time span by which Beas assigns the second work order is longer. The routing operation of the second work order will still be 8 hours (as well as the capacity occupied on the resource), but can take only 4 hours from Day 1 and will have to take 4 hours from the second day. This is why you will have representation in the APS GANTT for the second work order that is longer than the first one. If you check the Resource > Dispatches > Detail, you will see the calculated time zones for the second work order: Day 1: 6am – 10am ( 4 hours, as the remainder of the capacity has been taken by work order 1) Day 2: 6am – 10am (the remaining 4 hours of work order 2)

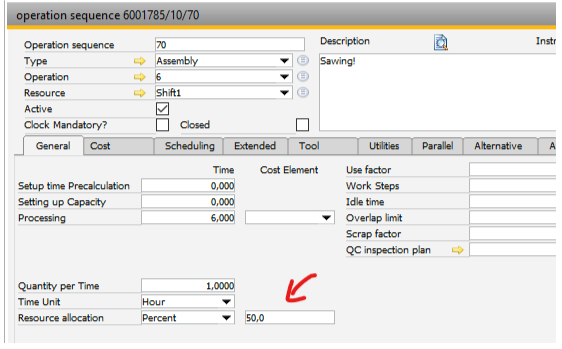

Example 3: Work order 1 and 2 have been set to start on the same Day by APS with forward scheduling. Each of the work orders has one routing position and each of them lasts for 6 hours. You have assigned a resource allocation of 50% for each of the routing positions.

In this situation, the Detailed planning will not be used. The result of an APS forward scheduling will be: The system plans the complete day, but on both work orders it will have the same start date/time, and they will be in parallel because of the 50% setting at the routing position resource allocation. The system will represent both work orders with a longer time span (12 hours each), but each of them will still occupy only 6 hours of resource capacity.

|