|

|

|

Production type for warehouse related order

|

Determines the specification of the production type when creating a new work order, if it is not an order-related work order.

Production types are set up in Configuration Wizard > Production > Master Data > Production Types.

|

Production type for sales order

|

Determines the specification of the production type when creating a new order-related work order.

Production types are set up in Configuration Wizard > Production > Master Data > Production Types .

|

Default Actual Precalculation

|

Enabled (Default): A work order is created from the Precalculation if a work order was created from a sales order in which a Precalculation is stored.

Disabled: A stored Precalculation is not considered. The master data is always used as a reference.

beas 9.2 PL: 06 workorderfromcalculation J/N

|

|

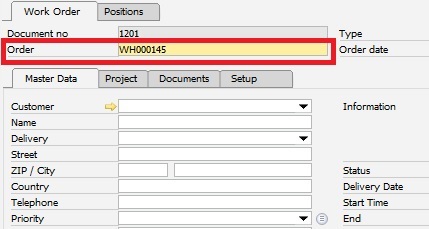

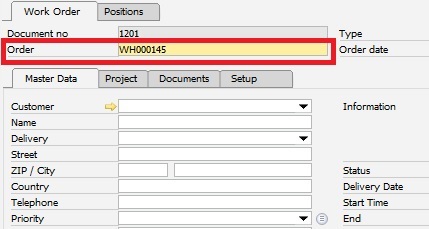

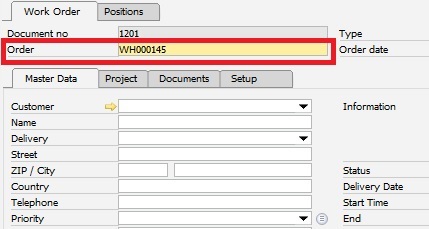

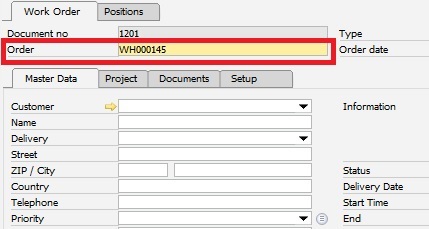

Automatic Numbering

|

A work order has two document numbers: There is a consecutive counter that cannot be influenced and a counter that can be freely defined. The second counter can be allocated during a new manual creation if this option has been activated.

Note: If a work order was created from a sales order, this setting has no effect.

See  Number creation Number creation

|

|

Make to stock Work order number template

|

Option is only visible if "Automatic Numbering" was activated. The current counter is defined in Current counter status.

In the template the lower case "x" is replaced by the current counter. Number of x equals the number of initial 0. Other placeholders ( e.g. uppercase X) are not supported.

Note: If the work order was created from sales order, this setting has no effect.

Example:

A-xxxx: A-0001, A-0002 etc.

See  Number creation Number creation

|

|

Current counter status

|

Current counter reading for WO number for stock related work orders or for sales order related work orders, if you defined a counter "[xxx]" inside the "sales order call up work order number template".

|

Sales Order Call up Work order number template

|

If a production order is created from a sales order or pre-invoice, the production order number can be generated from a reference number of the sales order. For this purpose it is possible to define an SQL template.

You can define the following settings:

Counter

|

The numbering "current counter" is used. This is the same counter as in the case of warehouse-related work orders.

If you choose "Counter", Beas inserts "xxxx" as a "template" in this field.

It uses the same counter (= option current counter) as for warehouse-related work orders.

See Option "Make to stock Work order number template" above.

If you want the same counter structure as in warehouse-related work orders, insert the same template, e.g. "WHxxxx" for counter WH0001,WH0002, and so on.

Info:

Warehouse-related and sales order-related work order is used in this same counter.

Example

xxxxx

the x = the counter, count of x = the length of the number

xxx = 001,002,003

xxxx = 0001,0002,0003

SalesOrder-xxxx generate SalesOrder-0001,SalesOrder-0002 ...

You cannot combine SQL Sequence with the counter.

If you want the same counter as warehouse-related work order, then insert the same template in this option as in the warehouse template.

|

Standard

|

Uses sales order number " - " Line number.

For example, sales order 3000 Line 2 returns 3000-2 as order number.

Note: For pre-invoices the corresponding pre-invoice document number is used.

|

Sales Order - Line

|

Like "Standard" (not removed for compatibility reasons)

|

Sales Order / Line

|

Same es "Standard", but using "/" as delimiter (z.B. 3000/2)

|

[SQL Sequence]

|

You can access all fields of table ORDR and RDR1. If it is a pre-invoice, all ORDR and RDR1 will be replaced by OINV and INV1. template.

(Example: "ORDR"."CardCode" = Customer order).

The placeholders [docnum] and [visline] are replaced by the order number and line number (already correctly formatted). An SQL string must always return the type "String". Type "[counter]" uses the production standard counter.

Max. lenth = 50 chars,

If the result > 50 chars, the program create an error.

Example: Docnum and ItemCode

[docnum]||'-'||"RDR1"."ItemCode"

Would return order number+article number.

Example: Docnum and Line num as SQL String

rtrim(CAST(~"ORDR~".~"DocNum~" AS char(30)))||'-'||+rtrim(CAST(~"RDR1~".~"VisOrder~"+1 AS char(30)))

|

See Edit work order

See  Number creation Number creation

Variable: auftr_abruf

|

|

Approved

|

The approved switch is located in the Work order position. The underlying assembly structure receives the sames status.

beas9.0-004-044-000, woconfirmed

|

|

Approved at Sales Order

|

The approved switch is located in the Work order position. The underlying assembly structure receives the sames status.

Select:

Yes

No

Like sales order = status of switch is taken from Sales order - Logistics - Approved

Note: Setting is only taken into account, if the work order is created directly from sales order (using the function SO to WO), not if it is manually created.

beas9.0-004-044-000, wo2orderconfirmed

|

|

Default Priority

|

A priority can be defined here that is entered by default when creating a new work order.

See Priority

|

Default Name

|

The default name when the work order is created manually.

|

Assembly Position Increments

|

Increments for numbering the assembly position. The value is 10 by default.

|

Bill of Materials Increments

|

Increments for numbering the bill of materials position. The value is 10 by default.

|

Work Order Increments

|

Increments for numbering the routing item. The value is 10 by default.

|

Warning if no BOM

|

An error message is issued if no Bill of materials is stored when the work order is created.

Error Text: No bill of material exists for item xxx Work order y/z was created without (..) (faufstl05)

A message is created (extended error message) at the same time (see Configuration Wizard > System > Extended Error Message).

|

Warning if no Routing

|

An error message is issued if no routing is stored when the work order is created.

A message is created (extended error message) at the same time (see Configuration > System > Extended Error Message).

|

Renumber BOM

|

Normally, the numbering used is according to the master data. If, for some reason, a new numbering is provided, this option must be activated.

|

Renumber routing

|

If active, routing is automatically renumbered at when a new work order is created.

|

Summarize phantom assemblies by item numbers

|

If this option is active, phantom assemblies are summarized by item numbers. If this function is enabled, a comparison between work order and original item is no longer possible and the Work order update does not function.

Error message: auftrs340: "Material summary is enabled..." is issued regardless of the use of phantom assemblies.

See Work order update

|

|

Apply inactive work sequence

|

If enabled, inactive operation sequences are also transferred to the work order and are set to inactive. The inactive operation is visible in the work order structure but is crossed out with a black line.

1. When active, and the operation in the WO master data is set to inactive:

a) In case of Work orders without documents (time receipt), the operation is deactivated by this setting.

b) In case of Work orders with documents (time receipt), the operation is closed.

|

2. When inactive, and the operation in the WO master data is set to inactive:

a) In case of Work orders without documents (time receipt), the operation is deleted by this setting.

b) In case of Work orders with documents (time receipt), the operation is closed.

If a previously inactive operation is activated in the WO Master Data, it will be activated in the WO, or if it does not exist in the WO, it will be inserted.

See Work order structure refresh.

|

See Active Flag in Routing Position.

|

Merge phantom assembly

|

Determines which assembly times and material are posted to in case of merging. An empty, not storage-related assembly (without BoM and routing) can be selected.

|

Sub-assemblies: consider lot size

|

Example

Assembly A contains 1 x order related assembly B

Assembly B has a lot size of 10

35 pieces of A are produced

If the option is active, the following structure is created:

35 * A

|_ BOM 35 * B

|___ Assembly 10 * B

|___ Assembly 10 * B

|___ Assembly 10 * B

|___ Assemblye 5 * B

If the option is disabled:

35 * A

|_ BOM 35 * B

|___ Assembly 35 * B

Attention:

Disabled: There is a 1:1 link between BoM and Sub Assembly

Enabled: There is a 1:n link between BoM and Sub Assembly

If you change the setting from "Enable" to "Disable" and Work orders with 1:n link exist, Beas always considers the first position only and ignores all other sub-assemblies.

Notes on disabling the option:

Close all work orders that have more than 1 sub-assembly per Bill of materials position.

Note: This option affects Precalculation. See Precalculation - Display and lot size

See Item master lot size Production

beas9.1-004-056 auftr_lotsize (Default N = not activ)

|

|

Precalculation material pricing

|

Specifies the pricing of materials when valuating assemblies.

|

WO refresh behavior

|

Specifies the behavior of Work order refresh:

- only if no documents exist: Refreshing of the Work order is only possible if there are no related documents (including reservations, issue or receipt documents). IMPORTANT: Refreshing is also not possible if the Work order has been printed.

- only add new information: Refreshing the work order only displays new information on new material positions or operations added to the master data in the work order. Information is added at the end of the actual WO structure.

- disabled: Refreshing a work order is not possible, and the function does not appear in the right-click menu.

- refresh: Changes in existing WO BoM and routing are possible (see also "WO refresh action" below).

Note: If reservations exist, the system will remove all the reservations during the Work Order Refreshing process.

|

|

WO refresh action

|

- BoM: The refresh function updates newly added BoM information.

- Routing: The refresh function updates newly added Routing information.

- All: The refresh function updates all newly added information.

NOTE: If in the WO there are links between the BoM and routing positions, we recommend to use option "All". The "BoM" and "Routing" options do not delete the links if the refresh process needs to close a Routing/BoM position.

Attention: If no documents have been created for the WO, the WO will be completely recreated upon the refresh action. BoM and Routing settings are ignored in this case.

|

|

Fast copy for lot size

|

If enabled, the creation of lot size WO's can be faster, by using an alternative way for "duplicating" the WO positions.

This setting only has impact on items with a defined lot size.

The activation also has some limitations:

- all settings are only done for the first WO position.

- the following lot positions are a 1:1 copy of the first lot.

- the last lot can be different if the quantity is different from the previous one.

Therefore, if you have e.g. a custom script, that applies some values that are different for each lot, it is recommended, not to activate this setting.

If the WO creation process has to create different positions (e.g. positions are created by script or SO to WO combines more than one position to one WO), the "fast copy" process will be automatically disabled for this WO.

|

|

![]() Number creation

Number creation