Lot size - Precalculation

- "Calculation lot size" is the default lot size for the calculation.

- "Production lot size" is the maximum lot size and is relevant for the calculation of fix costs.

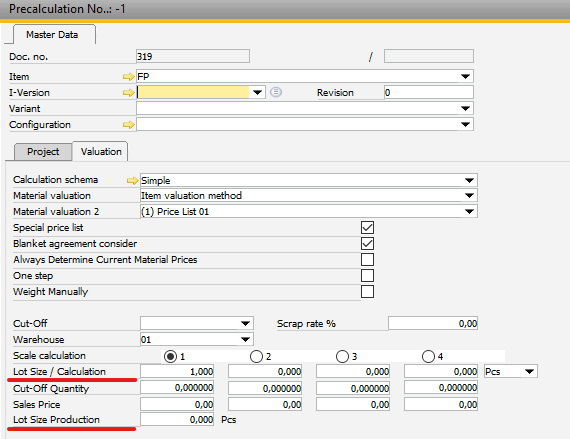

Window pk_haupt_edit.psr

The production lot size affects:

- Setup times in a Bill of materials position.

- Fixed times (Quantity per = 0) in routing positions.

- Fixed surcharges.

- Purchase prices (special price list).

- Price per lot size

In sub-components the calculation uses the production lot size. If you activate Configuration wizard > Production > Create > Sub-assemblies: Consider production lot size, the system uses the production lot size defined in the sub-component, otherwise the lot size of the main item.

Example:

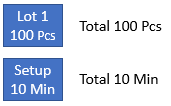

Routing position 10 Min setup time, 5 Min Mach+Labor time

Lot size calculation: 100, Production: 0 (ignore it)

Cost = 10 Min + 100* 5 Min = 510 Minutes * cost rate

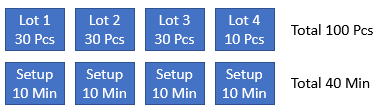

Lot size calculation: 100, Production: 30

In this case we must calculate the production 30 + 30 + 30 + 10 = 4 times.

Cost = 4*10 Min + 100*5 Min = 540 Minutes * cost rate

Working with sub-assemblies

If consider Sub Assemblies is activated, the system split the sub-assemblies too

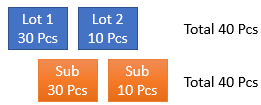

Example:

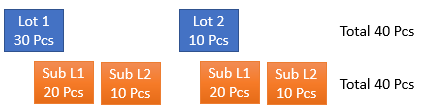

Production 40 Pcs, Lot size 30 Pcs

Sub assembly is order related, Production lot size = 0 Pcs (no lot size)

This case is a WO position-related process.

If an order-related sub-assembly has its own lot size, the system checks this, as well - but always per production level from the parent item.

Example : Lot size 20 Pcs

In this case the setup time will be multiplicated with 4 in the sub assembly

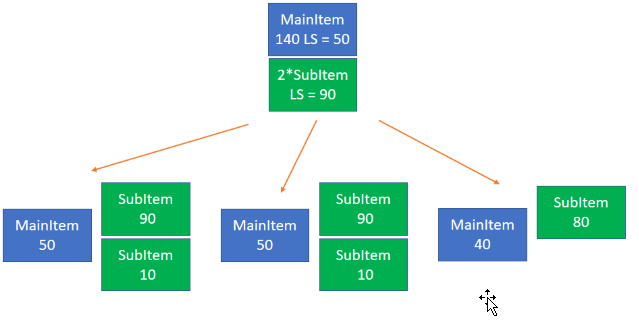

2. Example for order-related sub-assembly:

-Main and sub-item are order related, the lot size of the main item is 50

-We need the sub-assembly 2 times per main item, the lot size of the sub-item is 90

-We want to produce 140 Units of the main item

Result:

-We need to produce 3 lots for Main item (50 + 50 + 40)

-For the first and second lot of the main item we need 2 lots of the sub-item (90 + 10)

-For the last lot of the main item we need 1 lot of the sub item (80)

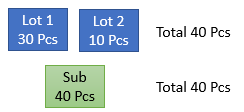

Stock-related

if the sub-assembly is stock-related, the sub-assembly ignores the lot size from the parent assembly:

if the stock related sub-assembly has its own lot size, the system uses it without relation to the lot size of the parent item.

Note:

This is working differently than in Beas 2020.11 or older. If you need the old functionality, you can change this in a user event. See Script documentation.