This chapter describes how the lead time is calculated:

Delivery Date

If a production order is created from a customer order, the delivery time is considered first. The delivery time is the time between production order delivery date and customer order delivery date and is defined in the settings.

Customer order delivery date |

Scheduled in the customer order. |

|---|---|

Work order delivery date |

Defined in the production position, generally delivery date of customer order minus x workdays at time y. Both can be configured. |

End time |

Calculated completion date. |

Start Time |

Calculated start date. |

Start date |

Calculated or manually specified start date. |

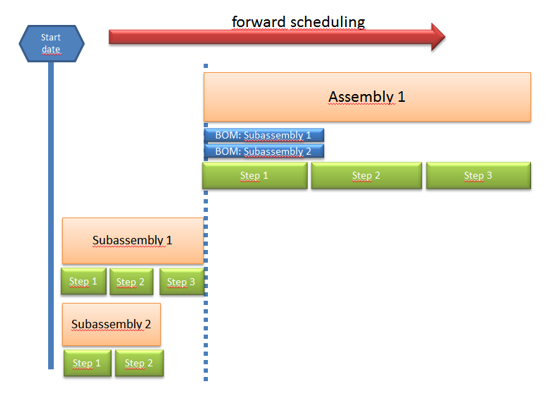

Use forward Scheduling for

•planning exact start date for every routing step •if you need resource resource-optimized planning

The forward scheduling starts with defined Start date and calculates the complete structure. The system starts with the sub level and then continues with the main level.

In this example ▪"Assembly 1" can be produced only after all sub-assemblies have been finished. ▪last operations of the sub-assemblies are linked to the first operation of "Assembly 1".

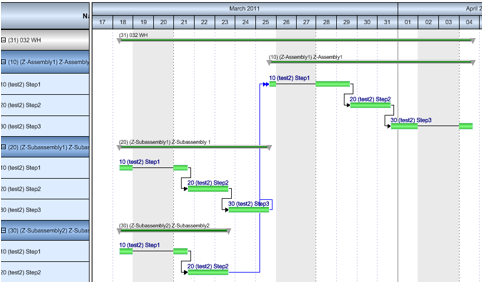

In APS Gantt view:

Note: For forward scheduling the APS License is mandatory. |

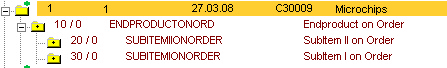

Structural processing

The structural calculation is shown in this example:

The "Endproductonord" assembly consists of "subitemiionorder" and "subitemionorder"

Production structure view

Before "Endproduct" can be started, the two subcomponents must be processed.

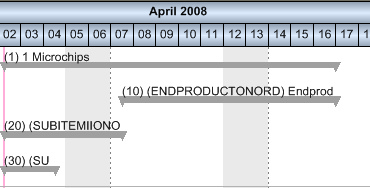

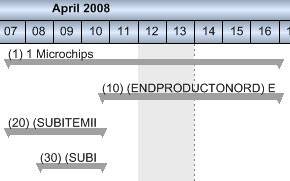

APS view, lines minimized – forward-scheduled

The image clearly demonstrates that in the time line work sequences 20 and 30 are started first and the upper assembly "Endproductonord" is only started when the assembly with the longer throughput time is ready.

Forward scheduling always works in a resource-oriented way here, i.e. earliest possible start.

Conversely, backward scheduling

APS view, lines minimized – backward scheduling.

In backward scheduling you start as late as possible (start 7 April). It can clearly be seen that assembly 30 starts later than assembly 20.

Routing Position

The time line of a work sequence consists of multiple parts.

Transfer Time Plan time - reported time Idle Time

|----------------------------|--------------------------------------------------------|-----------------------|

Start Time End time

Times for the resource are only reserved in the time between the start and end times. Closed work sequences are not calculated. Active logins are not considered.

For information on Calculation of target time see Calculation of target time

The next operation is dependent on the overlap time, i.e. the next operation starts on transfer time + overlap time + idle time excluding plan time (graphical view for forward scheduling only):

Afo 1 Transfer time Plan time - reported time Idle Time

|----------------------------|--------------------------------------------------------|-----------------------|

|------ Overlap limit ----|---- Idle time---|--> Next operation

Transferred times are specified in Resource under Resource -> Planning -> Transfer Time in Days or Resources -> Planning -> Transfer Times . Using the priorities, the idle time and the transfer time can be influenced.

Special feature: overlap and transfer time

If the following routing position is overlapping or parallel, the transit time does not apply to the following routing position, but rather to the routing position that is no longer defined as overlapping or parallel to this routing position.

Special feature: backward scheduling

Certain functions such as firming and material requirements inspection are not available and do not work in a resource-optimized way. Overlaps are supported but are not displayed correctly graphically.

Backward scheduling supports no detailed planning. Instead, it uses a "daily pot for a resource". This means that upon check of existing dispatches from other work orders only the time, but not the point in time (start) is checked.