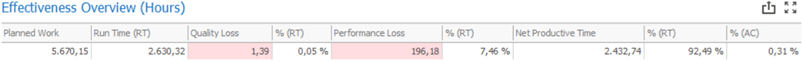

This single row report details the factory’s effectiveness for the selected parameters, combining the time range filter to the chosen resource groups or resources.

a)Planned Work: Sum of the total scheduled and executed production times for the resources;

b)Run Time (RT): Total executed production times for the resources, not considering setup times;

c)Quality Loss: Calculated lost times based on factors due to scrapped amounts from Time Receipts and QC rejections (QC Transfers into blocked warehouses);

d)% (RT): Quality Loss divided by Run Time (RT), resulting in how much of the run time was lost due to bad quality;

e)Performance Loss: Every time an operation takes longer than expected to be completed, the difference between actual times and planned times will be considered as performance loss (important: only underperformance affects the “Performance Loss” calculation; overperformance will not be discounted from “Performance Loss”);

f)% (RT): Performance Loss divided by Run Time (RT), resulting in how much of the run time was lost due to underperformance;

g)Net Productive Time: Run Time discounted from Quality Loss and Performance Loss, discounting in the real productive time for the entire company or selected parameters and filters;

h)% (RT): Net Productive Time divided by Run Time (RT), resulting in how effective the executed production times after were discounting the losses;

i)% (AC): Net Productive Time divided by Available Capacity (AC), resulting in the OEE calculation for the entire company or selected parameters and filters.