In Routing position > Extended you can define the Scrap of Material related to a routing position.

Example:

You must produce and fill 6 kg of paste.

15% is lost during filling.

Now you must calculate how many liters of paste are needed.

Calculation

Correct formula is: Quantity: (100 – Scrap % ) * 100

If you need 6 kg of finished product, you need

6 kg : (100 - (0.15) * 100 = 7.059 kg paste

If you see the opposite:

I fill 7.059 kg paste and lose 15% =

7.059 - (7.059 / 100 * 15) = 6 kg

In the Configuration wizard > "Behavior for Routing Scrap of Material % affects" you can define how the program should work.

The "Exceeding planned quantity allowed" affects BoM position - material scrap: The Minimum/Maximum percentage is calculated based on total quantity. see Configuration setting.

The following settings are available:

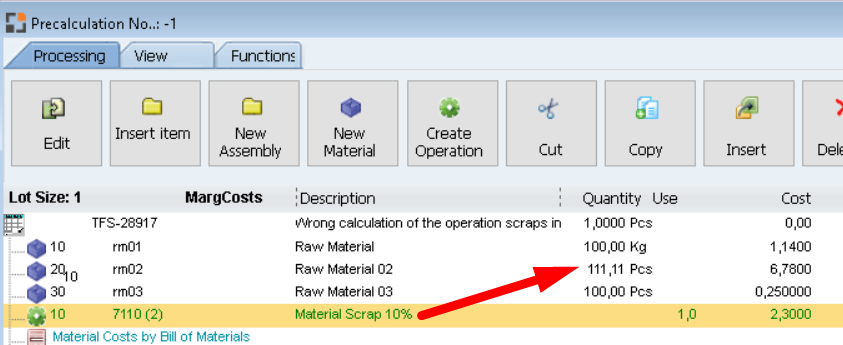

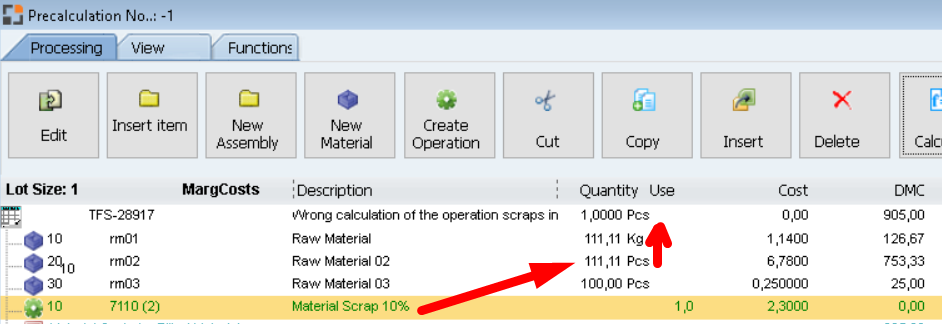

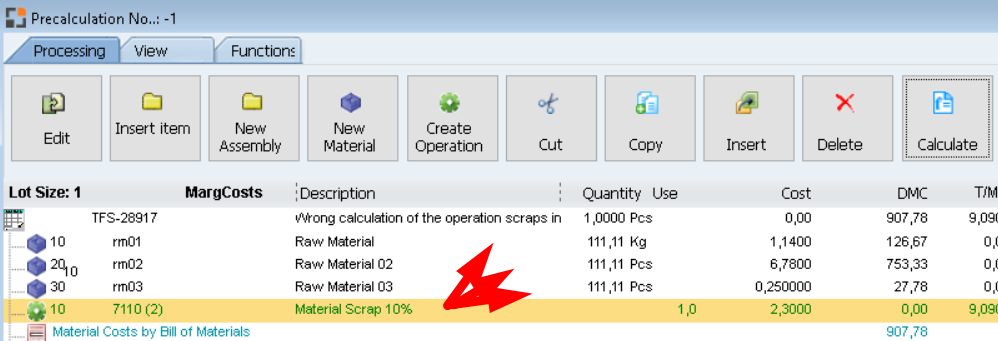

Result see this example:

|

This is the Standard setting

Example: When a bar is sawed, a scrap rate of 10% may incur. If the material is ground, the bar becomes even shorter, that is a longer length must be cut beforehand,

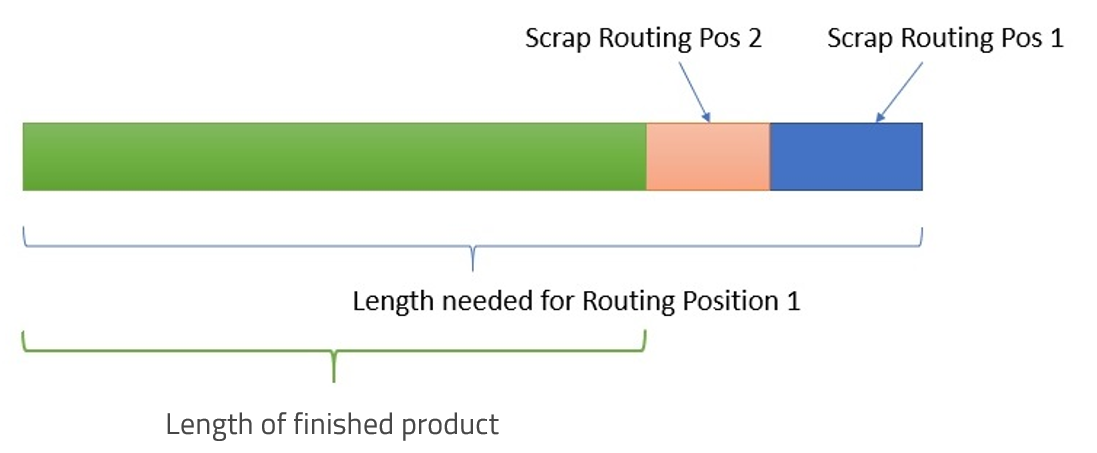

Example: We need a finished product with a length of 250 mm.

We start with 308.65 mm - sawn : scrap 10% = 277.78. Continue with 277.78 mm - ground : scrap 10% = 250 mm.

Calculation

Correct formula is: Quantity : (100 – scrap% ) * 100

Position 20 we need 250 : (100 – 10) * 100 = 277.78 The value is entered into the production BOM item, column "calculated scrap" as fix value.

|

|

Notes:

•This field is only visible when the parameter in Configuration wizard > Master data > routing > "operation related material scrap" is enabled.

•The Item Report – Item Structure report does not support Material Scrap factor on Routing Level.

•Enable this option only if absolutely necessary; the computation will take considerably longer.

•In Work orders this field is blocked, because scrap of material is determined only at the moment of creating the work order.

•When checking which routing positions are considered, the following criteria apply:

- Validity date

- Active (no formula, no quantity check)

- Variants (A–Z)

Not checked:

- Variants formulas, Product configurations