In Beas we have 2 different lot sizes:

Production lot size: Maximum lot size for production (inventory UoM)

Calculation lot size: The average lot size for price calculation, e.g. for using in batch calculation (inventory or production UoM)

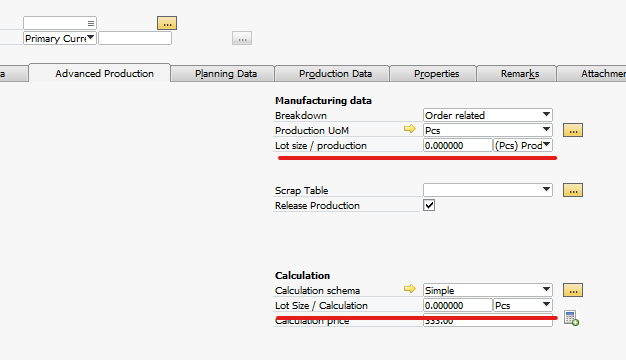

See Item Master Data - Advanced Production

The lot size can be defined in Production UoM or inventory UoM.

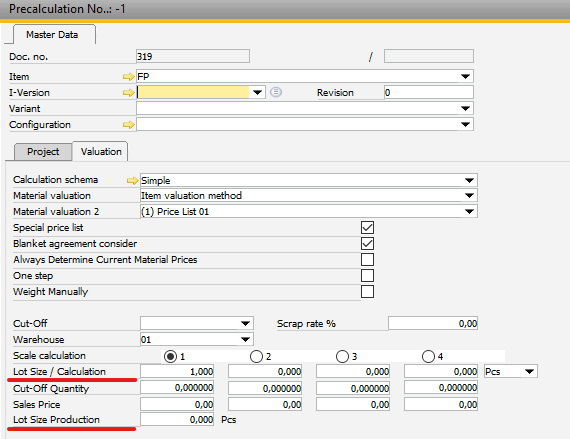

Lot size - Precalculation

- "Calculation lot size" is the default lot size for the calculation.

- "Production lot size" is the maximum lot size and is relevant for the calculation of fix costs.

Window pk_haupt_edit.psr

The production lot size affects:

- Setup times in a Bill of materials position.

- Fixed times (Quantity per = 0) in routing positions.

- Fixed surcharges.

- Purchase prices (special price list).

- Price per lot size

In sub-components the calculation uses the production lot size. If you activate Configuration wizard > Production > Create > Sub-assemblies: Consider production lot size, the system uses the production lot size defined in the sub-component, otherwise the lot size of the main item.

Example:

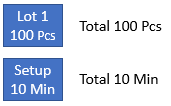

Routing position 10 Min setup time, 5 Min Mach+Labor time

Lot size calculation: 100, Production: 0 (ignore it)

Cost = 10 Min + 100* 5 Min = 510 Minutes * cost rate

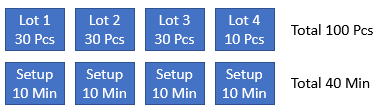

Lot size calculation: 100, Production: 30

In this case we must calculate the production 30 + 30 + 30 + 10 = 4 times.

Cost = 4*10 Min + 100*5 Min = 540 Minutes * cost rate

Working with sub-assemblies

If consider Sub Assemblies is activated, the system split the sub-assemblies too

Example:

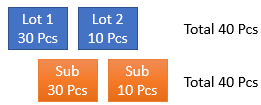

Production 40 Pcs, Lot size 30 Pcs

Sub assembly is order related, Production lot size = 0 Pcs (no lot size)

This case is a WO position-related process.

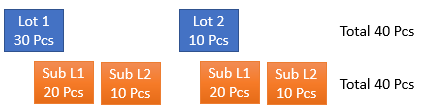

If an order-related sub-assembly has its own lot size, the system checks this, as well - but always per production level from the parent item.

Example : Lot size 20 Pcs

In this case the setup time will be multiplicated with 4 in the sub assembly

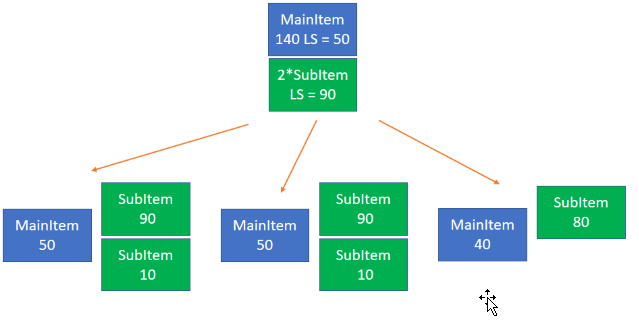

2. Example for order-related sub-assembly:

-Main and sub-item are order related, the lot size of the main item is 50

-We need the sub-assembly 2 times per main item, the lot size of the sub-item is 90

-We want to produce 140 Units of the main item

Result:

-We need to produce 3 lots for Main item (50 + 50 + 40)

-For the first and second lot of the main item we need 2 lots of the sub-item (90 + 10)

-For the last lot of the main item we need 1 lot of the sub item (80)

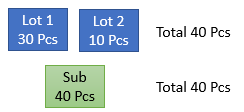

Stock-related

if the sub-assembly is stock-related, the sub-assembly ignores the lot size from the parent assembly:

if the stock related sub-assembly has its own lot size, the system uses it without relation to the lot size of the parent item.

Note:

This is working differently than in Beas 2020.11 or older. If you need the old functionality, you can change this in a user event. See Script documentation.

Work order

If the work order is created by "Sales order to Production order", Beas Object, Beas Service Layer or Integration Hub, the system automatically checks the production lot size on main level and in sub-level only if you activate Configuration wizard > Production > Create > Sub-assemblies: Consider production lot size.

Note: If you activate "Consider Lot size production", the calculation in MRP can take longer.

![]() Working with Lots size

Working with Lots size