APS means Advanced Planning and Scheduling. The APS extends the planning functions of the Beas Basic license with further functions for detailed planning.

New or existing work order positions are calculated by using predefined calculation types.

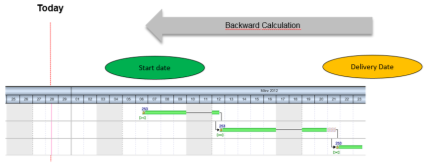

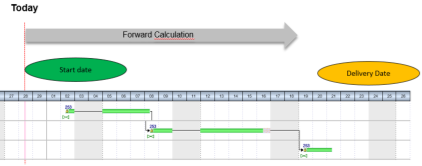

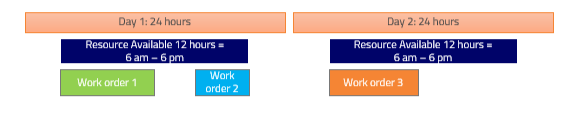

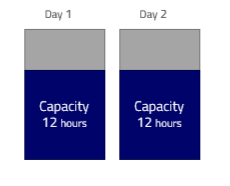

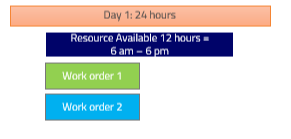

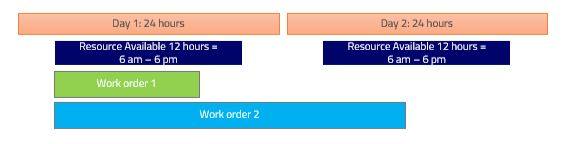

Depending on the calculation type, the work order positions are calculated forwards or backwards and the material availability is checked. The work order then is automatically scheduled, while considering the resource limits. The calculation can be done forwards, starting from a start date (resource-optimized) or backwards, starting from a delivery date (stock-optimized). The calculation type is used to reduce the transition times in two steps.

In a calculation type, various parameters are defined to control the behavior of the calculation:

- the scheduling direction

- the consideration of material receipts

- buffer times.

There are five (5) default calculation types in beas. See Default Calculation Methods. Besides using the predefined calculation types it is possible to create your own in APS.

Define calculation types under: Production > Capacity planning > APS Calculation type. In the planning settings (Production > APS > Open scheduling) you can configure which calculation method is available in this plan. If a new calculation method is defined, you must remember to store this in the planning, as well.

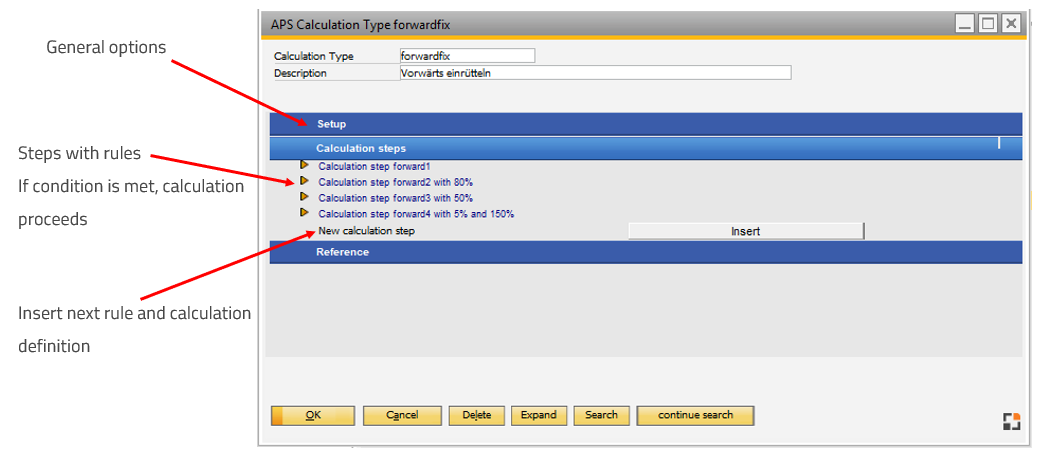

A calculation method has the following structure:

Window fert_xgantt_methode_edit.psr

To facilitate configuration, the setting is specified using a wizard. The settings are well-documented there and can generally be made without documentation.

Master data

Window system_option_struktur.psr

Field |

Description |

|

|---|---|---|

Calculation type |

Unique ID, the name of the calculation type. |

|

Description |

|

|

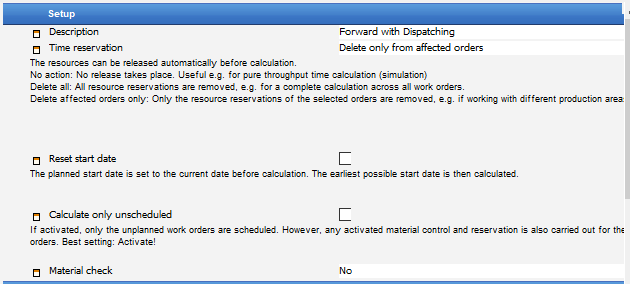

Time reservation |

|

|

Reset start date |

If activated, the planned start date is set to the current date before the calculation. The earliest possible start for a production structure is then calculated. |

|

Calculate only unscheduled |

If activated, only the unplanned work orders are scheduled. However, any activated material control and reservation is also carried out for the planned work orders. It is recommended to enable this option. Work orders marked for calculation, but not calculated due to this setting, receive the "fixed" value in field "last calculation". |

|

Material check |

|

|

Consider planned WO not in list (BETA)

|

If activated, the Material check will consider all open work orders that already have the status "APS planned". This means all the planned Work orders will influence the available material, regardless of whether they are part of the orders to be calculated or not.

|

Calculation steps

Any number of calculation steps can be defined.

Calculation step |

Unique ID |

|||||||

|---|---|---|---|---|---|---|---|---|

Sorting |

Sequence. By default, this value is set to “2”. If the user inserts a new calculation step (last field in this section), the system creates a new sub section “Calculation Step 3 3” adding 1 to the previous counter in the Sorting and Description fields. |

|||||||

Description |

Description of calculation step. |

|||||||

Execution condition |

|

|||||||

Scheduling Direction |

|

|||||||

Latest start |

|

|||||||

Consider scheduling ID |

|

|||||||

Work step fixation |

|

|||||||

Consider material entry |

If this is activated, the receipt date calculated from the material control is used at the earliest start date for the affected positions. However, this does not affect fixed positions. |

|||||||

Fix logged task |

Specify how currently reported positions are treated. If an operation is in work (started) and a calculation is started in APS, the operation is not moved. The position is fix. Only applies to forward scheduling. |

|||||||

Simulation |

The calculation is performed as a simulation. This means that calculated times are not reserved or written to the reservation table and visualization table. Only the start date or end date is calculated. By default, this option is unchecked. When the simulation check box is active, the system does not update fields calculation "Start time" or "End Time" in any scenario. |

|||||||

Consider capacity limits |

|

|||||||

Consideration of time receipts |

|

|||||||

Exploit the full capacities |

|

|||||||

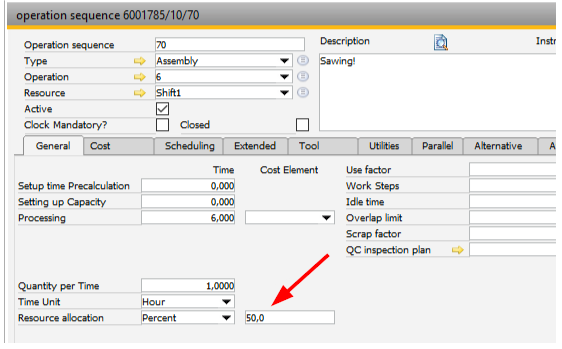

Transit time in % |

Specifies the % of transit time to be considered. By default it is the stored priority setting according to the production order. A percentage value can be entered. The lower the value, the lower the throughput time is. See Transit time. |

|||||||

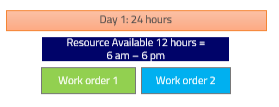

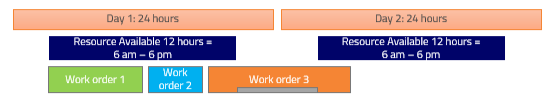

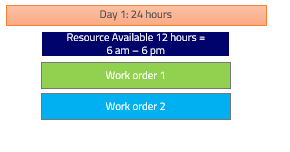

Capacity overload limits in % |

Specifies the percentage the resource may be overloaded by. Example: If the resource has a planned capacity of 8 hours / day and 150% is set, the order can schedule this resource for 12 hours. By default it is the stored priority setting according to the production order. A percentage value can be entered. The lower the value, the lower the throughput time is. |

|||||||

External operation: Consider goods receipt from PO |

|

|||||||

External operation: Time of inflow |

This option is available only if the field External Operation: Consider Good Receipts from PO is checked. At purchase only the date can be entered, not the time, so an default time (standard: 3pm (15:00)) is defined. The usual warehouse delivery time should be entered. |

|||||||

Set work sequences logged in |

If a work sequence is currently logged in and this option is active, the start time for this work sequence is ALWAYS the present. This only works for forward-scheduling. |

Reference

Report |

Enable to make the calculation type as available in APS list view. By default, this option is unchecked. |

|---|---|

Gantt Display |

Enable to make the calculation type as available in the Gantt display. By default, this option is unchecked. |