Function

|

Description

|

bom_additem

|

object=ue_api_wo=bom_additem=<belnr_id>=<belpos_id>=<itemcode>=<qty>

qty in using-unit (menge_verbrauch)

return in "<e_pos_id>" the new pos_id

You cannot add a phantom item to a workorder material list (incl. existing routings)! You cannot add a phantom item to a workorder material list (incl. existing routings)!

|

|

bom_close

|

Example

object=ue_api_wo=bom_close=<belnr_id>=<belpos_id>=<pos_id>

|

|

bom_quantity

|

if quantity of assembly changed or from Bill of material position, the total quantity must be calculated

For complete work order

wo.bom_quantity=x

For work order position

wo.bom_quantity=x=y

For Bill of Material position

wo.bom_quantity=x=y=z

|

|

bom_reopen

|

Example

object=ue_api_wo=bom_reopen=<belnr_id>=<belpos_id>=<pos_id>

|

|

bom_replaceitem

|

setvar=ls_newitemcode=[new itemcode]

declare=mywo=ue_api_wo

mywo=bom_replaceitem=<ll_belnr_id>=<ll_belpos_id>=<ll_pos_id>=<ls_newitemcode>

You cannot replace a material in a workorder position with a phantom item or assembly! You cannot replace a material in a workorder position with a phantom item or assembly!

|

|

bomcandelete=belnr_id,belpos_id,pos_id

|

beas check all subassembly from this position and the bom-Position self. Return in Value "value" "1"=can delete , -1 can not delete

object=ue_api_wo=bomcandelete=<belnr_id>=<belpos_id>=<pos_id>

messagebox=<value>

|

|

checkrelease

|

object=ue_api_wo=checkrelease=fttyp=..<tab>itemcode=...

if <return> = success then

// all ok

else

messagebox=error$<value>

end if

Properties

fttyp

|

beas work order type beas_fttyp

|

itemcode

|

assemlby itemcode

|

stlitemcode

|

id from used bill of material. empty=same as itemcode

|

routingid

|

id from routing plan. empty = same as itemcode

|

deliverydate

|

date of delivery. empty=today

|

version

|

Version of assembly. Empty = don't check version

|

Return

failure = error. In "value" you've the error message

success = all ok

|

|

closeposition

|

declare=mywo=ue_api_wo

mywo=closeposition=<str_parm.belnr_id>=<str_parm.belpos_id>

Before closing, all necessary tests would be conducted.

There must be no open feedback exist.

A "Close" under certain circumstances can NOT be undone.

|

|

copy_wopos

|

object=ue_api_wo=<from-belnr_id>=<from-belpos_id>=<to-belnr_id>

insert this position in at last in work order <to-belnr_id>

beas9.0-000-001-007

|

|

copy_workorder

|

object=ue_api_wo=<belnr_id>

messagebox=<value>

display -1 = error otherwise the new number

|

|

deleteworkorder

|

you don't need to load this

object=ue_api_wo=deleteworkorder=<belnr_id>

if <return> = -1 then

// error handling

end if

|

|

delposition

|

Example Delete Workorder-Position

declare=mywo=ue_api_wo

mywo=delposition=<belnr_id>=<belpos_id>=0

All necessary tests would be conducted before erasing.

If position is complete or feedback exists, no cancellation is possible.

beas delete all eraseable sub-Positionen and close the rest. In this case base close the actual position and clear the WIA-Accounts.

If the assembly has sub-groups with feedback, a cancellation is not possible.

The script workordermanagement:delstl() will be called. Is this a failure, a cancellation is not possible.

The script workordermanagement:delpos() will be called. Is this a failure, a cancellation is not possible.

Delete BoM-Position

declare=mywo=ue_api_wo

mywo=delposition=<belnr_id>=<belpos_id>=<pos_id>

You can check the deletable of this position with "bomcandelete"

You cannot delete a phantom item (because you will not no the contents of this item)! You cannot delete a phantom item (because you will not no the contents of this item)!

|

|

ftpos_refresh

|

declare=mywo=ue_api_wo

mywo=ftpos_refresh=<str_parm.belnr_id>=<str_parm.belpos_id>

Manufacturing assembly will be removed and re-imported. Working consequences, where feedback exists will not be deleted (depending on the option).

Whether an upgrade is possible, is dependent on other settings. If the assembly or production order is closed, no update is possible.

|

|

ftzuordnung=<parameter>

|

Parameter with tab

belnr_id,belpos_id

|

Check workorder ...

|

receipt

|

Check for this receipt-document

|

distnumber

|

this is the distnumber from receipt-document.

Works only with batches!

|

issue

|

check only for this issue-document (optional)

|

getissue

|

get the issue-document automatically (examle for backflushing-procress) ... get the last issue-docentry which is created 4 min before the receipt document.

|

beas9.9-000-003-000

destroy=lds

declare=lds=ue_datastorevalues

lds=select "BEAS_FTPOS"."BELNR_ID"+0 as "BELNR_ID","BEAS_FTPOS"."BELPOS_ID"+0 as "BELPOS_ID" &

from "BEAS_FTPOS" &

inner join "OITM" on "OITM"."ItemCode"="BEAS_FTPOS"."ItemCode" and & ("OITM"."ManBtchNum"='Y' or "OITM"."ManSerNum"='Y')

for ll_loop=1 to <lds.rowcount>

lds.setrow=<ll_loop>

object=ue_api_wo=ftzuordnung=belnr_id=<lds.belnr_id><tab>belpos_id=<lds.belpos_id>

next

destroy=lds

|

|

|

getbomquantitysql

|

This part sequence requires the tables "beas_ftpos" and "beas_ftstl"

declare=mywo=ue_api_wo

select "BEAS_FTSTL"."POS_ID",<mywo.getquantitysql> as "Quantity" from "BEAS_FTSTL","BEAS_FTPOS" where "BEAS_FTSTL"."BELNR_ID"="BEAS_FTPOS"."BELNR_ID" and "BEAS_FTSTL"."BELPOS_ID"="BEAS_FTPOS"."BELPOS_ID"

|

|

getsubassembly=belnr_id,belpos_id,pos_id

|

object=ue_api_wo=getsubassemlby=<belnr_id>=<belpos_id>=<pos_id>

messagebox=<value>

Return as example: "20,30,40"

|

|

gettimesql

|

The partial sequence required the tables beas_ftapl,beas_ftpos and beas_ftapl

declare=mywo=ue_api_wo

select "BEAS_FTSTL"."POS_ID",<mywo.gettimesql> as wotime from

"BEAS_FTAPL" inner join "BEAS_FTPOS" on "BEAS_FTAPL"."BELNR_ID"="BEAS_FTPOS"."BELNR_ID" and "BEAS_FTAPL"."BELPOS_ID"="BEAS_FTPOS"."BELPOS_ID" left outer join "BEAS_APLATZ" on "BEAS_FTAPL"."APLATZ_ID"="BEAS_APLATZ"."APLATZ_ID"

where "BEAS_FTAPL"."BELNR_ID"=<str_parm.belnr_id> and "BEAS_FTAPL"."BELPOS_ID"=<str_parm.belpos_id>

select beas_ftstl.pos_id,<mywo.gettimesql> as wotime from

beas_ftapl inner join beas_ftpos on beas_ftapl.belnr_id=beas_ftpos.belnr_id and beas_ftapl.belpos_id=beas_ftpos.belpos_id left outer join beas_aplatz on beas_ftapl.aplatz_id=beas_aplatz.aplatz_id

where beas_ftapl.belnr_id=<str_parm.belnr_id> and beas_ftapl.belpos_id=<str_parm.belpos_id>

|

|

inventoryaudit

|

wo=inventoryaudit=docnumber=posnumber=routingnumber

if <value> = -1 then

message=info$<valuetext>

end if

Executes an Material

Executes inventory audit for the work sequence.

Return value will be stored in "value"

-1 Inventory not enough

1 Inventory OK

If return value is -1 so the reason will be stored in Variable <valuetext>.

|

|

|

|

loadworkorder

|

Load work order in memory and allow to change properties on workorder level or add / change work order positions on position level

Add Line to existing work order

declare=wo=ue_api_wo

wo=loadworkorder=1411

wo.line.add

wo.line.itemcode=FP

wo.line.quantity_ve=5

wo.line.belpos_id=100

wo.line.save

destroy=wo

Change quantity in existing work order

declare=wo=ue_api_wo

wo=loadworkorder=1411

wo.line.gotobelpos_id=10

wo.line.quantity_ve=15

wo.line.save

// Now we must calculate total quantity in BoM

wo.bom_quantity=1411=10

destroy=wo

|

|

opcandelete=belnr_id,belpos_id,pos_id

|

return in value: -1 = you can't delete, 1 = you can delete

beas check beas_arbzeit,beas_ftstmp,pch1,por1

object=ue_api_wo=opcandelete=<belnr_id>=<belpos_id>=<pos_id>

messagebox=<value>

|

|

refreshschema=belnr_id=belpos_id

|

This method delete the current schema on BEAS_FTPOS_SCHEMA and insert the updated selected schema.

object=ue_api_wo=refreshschema=<belnr_id>=<belpos_id>

|

|

reset / new

|

Delete all instances, insert new entries

|

residualquantity=belnr_id=belpos_id=pos_id=pos2_id

|

object=ue_api_wo=residualquantity=<belnr_id>=<belpos_id>=<pos_id>=<pos2_id>

messagebox=Residual Quantity = <value,#0.000000>

|

|

routing_close

|

object=ue_api_wo=routing_close=<belnr_id>=<belpos_id>=<pos_id>

|

|

routing_reopen

|

object=ue_api_wo=routing_reopen=<belnr_id>=<belpos_id>=<pos_id>

|

|

set

|

For set make a load.

you can set some properties in a workorder (beas 9.1 PL: 08)

declare=mywo=ue_api_wo

mywo=set=prior_id=1050=10=high

if <return> = -1 then

messagebox=you can not set the priority!

end if

destroy=mywo

Settigs for creation or refresh

function

|

Description

|

validdate=<date>

|

set valid date to check bom/routing valid date

you must set before create work order (beas 9.1 PL 8)

|

capacityautomatic=true/false

|

make capacity planing automatically after refresh or save (standard = true)

|

settings for existing work orders

Function

|

Description

|

prior_id=<belnr_id>=<belpos_id>=<value>

|

set the prior_id

|

apsstatus=<belnr_id>=<belpos_id>=<value>

|

set planed 1=planed, 0=unplaned

|

sperrung=<belnr_id>=<belpos_id>=<value>

|

lock the workorder J=locked, N=unlock

|

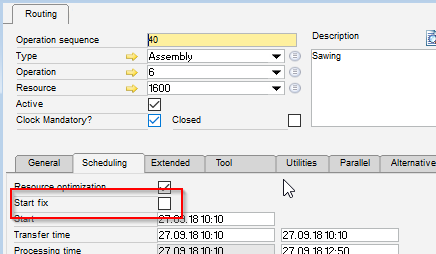

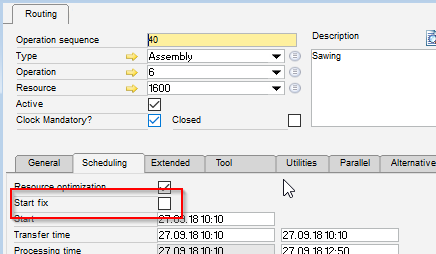

starttime,startzeit,startzeit_struktur

=<belnr_id>=<belpos_id>=<value>

|

Set the "startzeit_struktur" work order.

Date must be always equal or greater than today. If date is previous than today system will assign <today> date.

|

deliverydate, lieferdatum

=<belnr_id>=<belpos_id>=<value>

|

Set the deliverydate infor to work order position

|

fix, freeze

|

Set all routing position from this work order position and all sub positions to freeze (1) or unfreeze (0)

// freeze all routing position from this

// work order position and his sub structure

object=ue_api_wo=set=freeze=<belnr_id>=<belpos_id>=1

|

|

|

updateworkorder

|

wo=loadworkorder=<belnr_id>

// changes

wo=updateworkorder

|

|

wipclear=belnr_id=

belpos_id

|

we found an error in the account-settings. we want to make a automatic correction for all closed workorders

In this script we open the workorder, call the wipclear-Function and close the position.

destroy=lds

declare=lds=ue_datastorevalues

lds=select "BELNR_ID","BELPOS_ID","ABGKZ_DATE" from "BEAS_FTPOS" where "ABGKZ"='J'

for ll_loop=1 to <lds.rowcount>

lds.setrow=<ll_loop>

select "ABGKZ" from "BEAS_FTHAUPT" where "BELNR_ID"=<lds.belnr_id.value>

setvar=ls_abgkz=<wert1>

if <ls_abgkz> = J then

sql=update "BEAS_FTHAUPT" set "ABGKZ"='N' where "BELNR_ID"=<lds.belnr_id.value>

end if

sql=update beas_ftpos set abgkz='N' where belnr_id=<lds.belnr_id.value> &

and belpos_id=<lds.belpos_id.value>

setvar=e_date=<lds.abgkz_date,yyyy/mm/dd>

object=ue_api_wo=wipclear=<lds.belnr_id.value>=<lds.belpos_id.value>

sql=update "BEAS_FTPOS" set "ABGKZ"='J' where "BELNR_ID"=<lds.belnr_id.value> &

and "BELPOS_ID"=<lds.belpos_id.value>

if <ls_abgkz> = J then

sql=update "BEAS_FTHAUPT" set "ABGKZ"='J' where "BELNR_ID"=<lds.belnr_id.value>

end if

next

|

|

wocanclose

|

wocanclose=<belnr_id>=<belpos_id>

if <return> n= -1 then

message=error$you can not close this position

end if

|

|