|

|

|

Material valuation

|

Setting is visible only if continuous stocktaking was disabled.

Like manual posting Pricing according to Materials management > Manual postings > purchase parts/in house production > pricing posting.

Price list per warehouse In warehouse definition > extended for issuing material a price list can be stored. The price list is used when selecting this option. If no price is entered, pricing according to materials management is used.

General note: pricing according to price list for production issue: extended price lists or special price lists are not considered.

|

|

Automatic Material posting

|

Note: Check settings also under backflushing.

Note: This option does not affect the reservation window and allocation window.

Not Automatically

|

No automatic issue.

|

Work order Backflushing

|

Backflushing issue and automatic posting of the assembly is executed using the function Work order backflushing.

Note: No issue at reporting operations. No posting of assembly at confirmation of the last operation.

With Goods receipt the option Work order backflushing – book times automatically will be considered.

|

Last operation

|

Issue takes place when reporting the last operation with "clocking mandatory" All items are posted which have "Backflushing" as posting option in the inventory entry and which are not allocated to a position. If an item is allocated to another position, it is entered when the corresponding position is reported. The function "Materials management > backflushing" is blocked in this case.

|

First Operation

|

Same as "Last operation" but at the moment reporting the first operation.

|

Note: These settings affect only Beas (standard PC Version). WEBapps can have a different behavior.

This setting can be overridden by production types.

Exception: If the second option "work order backflushing" was selected.

See: Production types, Backflushing

Variable: fert_buchung_typ

|

|

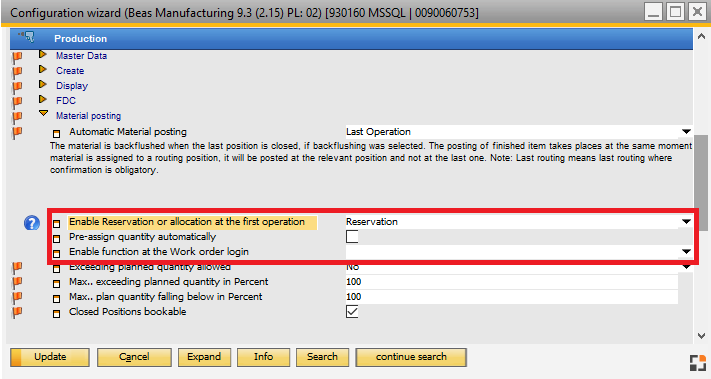

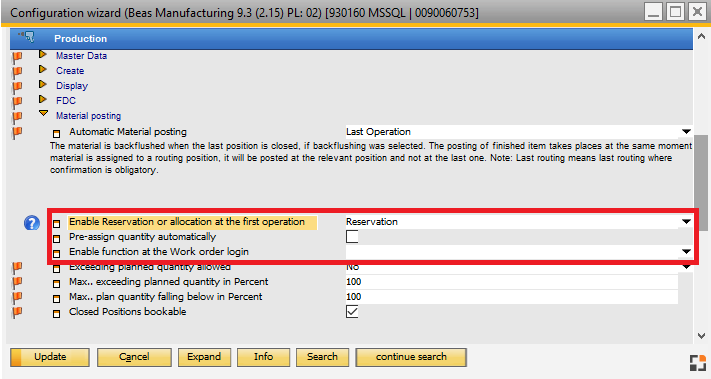

Enable Reservation or allocation at the first operation

|

With this feature you can define if the system should call the reservation window or allocation window. If set to inactive (or no setting), no reservation/allocation is done and the subsequent two options are not visible.

Reservation: This option calls the reservation window.

Allocation: This option calls the allocation window.

inactive: This option does not call any of these windows at the first operation.

|

|

Pre-assign quantity automatically

|

If this option is checked, the quantities for all Items will be pre-assigned automatically. Otherwise, the window is only opened without any assignment.

|

Enable function at the Work order login

|

Window system_option_struktur.psr

No: Nothing is defined, so the corresponding window is opened at the end at:

- logging off from a WO,

- a quick input,

- a production time receipt.

only at the work order login: Window is only called when logging in to a WO.

work order login or time receipt: Window is called when logging in to a WO or doing a manual production time receipt.

This feature is supported in Terminal apps: Login work order , Logoff work order, Production Time Receipt and Quick Input.

|

|

Exceeding of planned quantity allowed

|

Planned quantity is as given in work order +/- percentage of next setting below.

Select mode of exceeding planned quantity:

Setting

|

Meaning

|

Yes (default)

|

Allowed, without check (I).

|

Yes, with protocol (I)

|

Allowed. Errors are logged, and the work order is marked red in that case (IP).

|

No

|

Not allowed. Issue is canceled (B).

|

Query

|

Security query (Q).

|

Query with protocol

|

Security query (Q). If no material is issued a protocol entry is created for the work order, and its marked red.

|

Provide percentage:

Setting

|

Meaning

|

Maximum in Percent

|

The permitted overshoot of WO planned quantity. Maximum = planned quantity + (planned quantity * %)

|

Minimum in Percent

|

The permitted undershoot of WO planned quantity. Minimum = planned quantity - (planned quantity * %)

|

Percentage values: 1-99

0 = planned quantity

100 = no validation

Example:

Maximum in Percent = 50

Minimum in Percent = 50

Work order with 10 Pcs, Bill of Materials position 1 Pcs

Max. Material = 10 + (10/50*100) = 15 Pcs

Min. Material = 10 - (10/50*100) = 5 Pcs

Variable: fert_actionperexceeded, Standard: "I" (= Yes)

Note:

There is no validation in server mode (see Server administration).

BoM with negative quantities are not checked.

Time Receipt: Validation is according to partial and reported quantity.

Work order Backflushing: Validation is according to partial and reported quantity.

Material issue: At validation planned quantity = total planned quantity of the Work order position.

Limitations:

- No validations are executed for Manual issue and the WebApp WO Goods Issue!

- In case of issue documents that contain several lines of items from different warehouses and/or bin locations, the validation is ONLY executed on the first line of the document!

|

|

|

Maximum in percent

|

The permitted overshoot of WO planned quantity. Maximum = planned quantity + (planned quantity * %)

Value range: 0–99%. No validation in case of 100%.

Option is visible only if "Exceeding of planned quantity allowed" was not set to "Yes"

See "Exceeding of planned quantity allowed" above.

Variable: fert_permorpostmat, Default: 100 (in Percent, 100 = no check)

|

|

Minimum in percent

|

The permitted undershoot of WO planned quantity. Minimum = planned quantity - (planned quantity * %)

Option is visible only if "Exceeding of planned quantity allowed" was not set to "Yes".

See "Exceeding of planned quantity allowed" above.

beas9.0-004-000-000, Variable: fert_perminpostmat, Default: 100 (in Percent, 100 = no check)

|

|

Closed positions bookable

|

Affected only window "post manually" - Type "production" and only, if the position was selected by direct input or via barcode, the logged in user is a Superuser or he has the respective Rights. For more information see Authorization

|

|

![]() Webinar 8/2017, Part Configuration

Webinar 8/2017, Part Configuration ![]() Webinar: Financial accounting in beas Manufacturing

Webinar: Financial accounting in beas Manufacturing