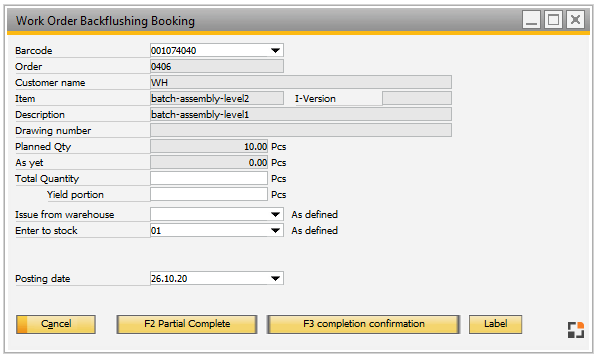

With this function you can create a receipt for the finished goods item and can backflush all necessary materials.

For this you only need

- Bar code of the work order position

- Quantity

fert_retrograd_abbuchen

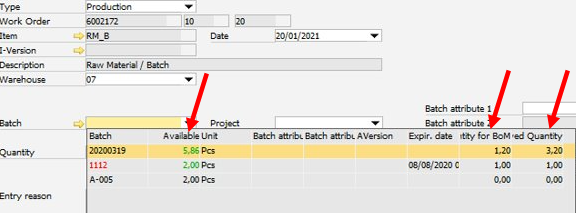

Backflushing is used to automatically remove material that is allocated to a work order and is marked as "backflush". The work order is selected for this (alternatively, the routing slip bar code can be scanned). Then, you specify the total quantity to be reported and the yield to be received. After inputting the number of units, the corresponding quantity of materials is issued and the finished good is entered.

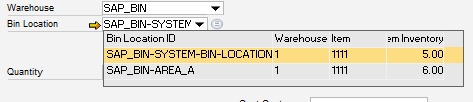

The material is issued from the inventory location stored in the BOM and the primary item inventory, respectively. If an inventory location is specified for "Issue from storage location", the material is posted from this inventory location.

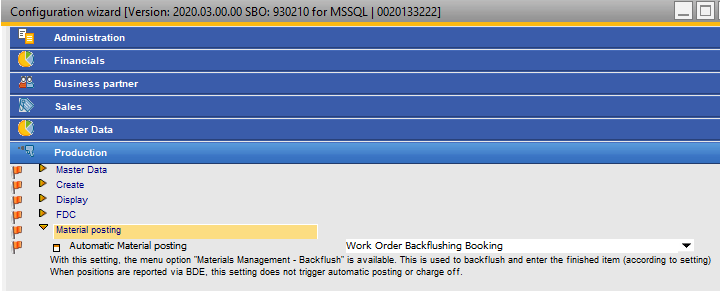

You can use this window only if this window is activated in the Configuration wizard.

In the Configuration wizard you must activate Production > Material posting: Work Order Backflushing Booking

Note: It is not possible to use this window in parallel to the backflushing functionality on last/first routing position! In Configuration Wizard > Production > Material posting > Backflushing you can define all additional Backflushing options.

Setup: Configuration > Production > Work Order Backflushing Booking

These settings affect the function Work order backflushing. They are visible only if in Configuration wizard > Production > Material posting > Material posting automatically at "Work order backflushing" was selected. PATH: Administration > System Initialization > Configuration wizard > Production.

see Material posting, backflushing

|

The posting process without closing the WO is done via button "Partial posting" or clicking on F2. The posting process with closing the WO position or WO is done via button "Final posting" or clicking on F3.

Completion confirmation – Button only visible if a) There are no uncleared time records. b) It is not about an overhead costs-order (definable in production type). c) Configuration wizard > Production > Valuation and posting of the assembly > Post finished parts when is not set to manually. d) The variable "lb_cannotclose" is not set to 1 in windowevent "cancloseorder".

windowevent cancloseorder setvar=lb_cannotclose=1 end event |

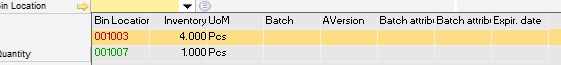

For items, set to "backflushing", quantities to be posted are automatically pre-allocated. Other entries are not pre-allocated.

Batches and serial numbers are only pre-allocated automatically, if in Configuration wizard > Production > Material posting and reservation > Backflushing > "Post batches also" or "Post serial numbers" has been enabled. Click on "pre-allocate" to pre-allocate batches or serial numbers manually. If batches or serial numbers has been reserved, independent of settings, these are always pre-allocated automatically.

Order of withdrawal is defined as:

Reserved goods Allocation warehouse Standard warehouse (as per BOM item or standard warehouse of item) Within this order the withdrawal rules from Configuration wizard > Production > Material posting and reservation > "Automatic batch issue by ..." apply.

All other warehouses are not considered, but you can withdraw manually from these warehouses. |

This window can be accessed from the menu as well as from the terminal.

|

If a report is stored, the button "Label" is displayed automatically, as soon as the work order was selected or posted. Always the information of the last posting is printed. There is no default report.

Setup: 1. Create a report. 2. Store the report in this window in the macro. 3. Close window and re-open. 4. Printing is available now.

Available variables: <docentry> = docentry from last document from table OIGE.DocEntry

Compatibility: Until beas9.0 Patch3 the button "Label" was displayed always and the report "Box label" was printed. If it was not existing, no label was printed.To enable printing, setup this report as described above.

See Macro |

![]() Webinar 8/2017, Part Work order Backflushing Booking

Webinar 8/2017, Part Work order Backflushing Booking