|

With this WebApp it is possible to stop an operation and close a work order position indicating the duration, the produced quantity and the remaining quantity to produce.

See basic functions in General Information on WEB APPS Version 2.1.

Header tab

In this tab you can provide the bar code of the WO position (operation) to stop. It is possible to scan the bar code of the WO position, or, alternatively, you can use the "Barcode" filter field to find the work order to stop. Tapping the  magnifying glass icon opens the "Opened work orders" screen: magnifying glass icon opens the "Opened work orders" screen:

Field Descriptions

Field

|

Description

|

Barcode

|

Using the bar code scanner, the bar code of the WO operation appears in the field, filling all WO-related information automatically (see third image above).

The information is displayed with WO number / WO positions and indicating the WO item name in italics right to the field name (see third image above).

|

|

Operation

|

The field is automatically filled with the information coming from WO-number

scanning or manual selection. The WO position number of the operation appears

in the field along with the name of the used Resource in brackets – see third

image above: 30 (1201) . The description of the operation is indicated in italics

right to the field name ("Function control" in our example above).

|

|

Resource

|

The field is automatically filled with the information coming from WO-number scanning or manual selection. The name of the Resource appears in the field, and its description is displayed right to the field name. The  magnifying glass icon opens the "Resource Search" filter screen. magnifying glass icon opens the "Resource Search" filter screen.

|

Time type

|

Select time type. The following 4 time types are available:

Processing, Setup time Precalculation, Rework, Quality control (see Time Types).

|

Duration

|

Right to the field name you can see the start date of the operation (see third image above), and the field automatically displays the time elapsed since the start date in minutes.

According to the app setup, you can make this field visible. See more details of extended App settings.

The field is not editable if "Field duration blocked" parameter was selected in Configuration wizard > FDC > View Time Receipts.

In the "Opened work orders" screen the passing of time is indicated in seconds in real time:

|

|

Quantity

|

Provide the remaining quantity to produce. If this field is filled, the Lines and the Line tab become inactive and the document is ready to be saved.

The unit of measure is indicated right to the field name.

|

Scrap

|

Provide the scrap quantity if necessary. Tapping on the  icon opens the "Scrap reasons" screen where you can select scrap quantity by scrap reasons and enter a description. icon opens the "Scrap reasons" screen where you can select scrap quantity by scrap reasons and enter a description.

|

Confirm completion

|

Select this check box to confirm completion of the operation and close the position. By leaving the check box blank, document qualifies as a partial time receipt.

|

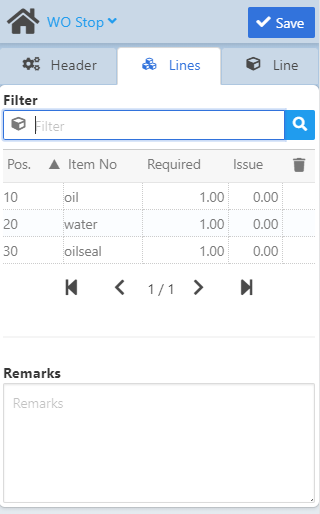

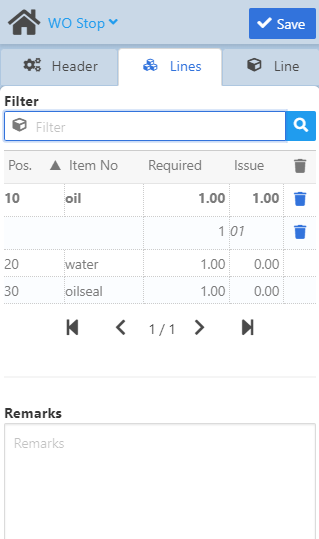

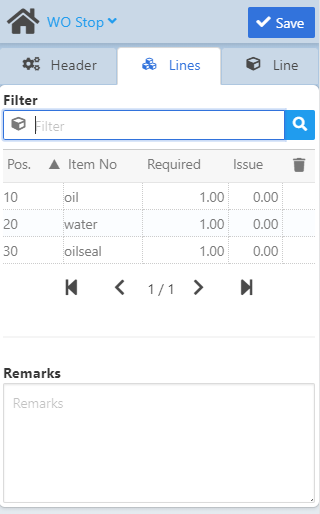

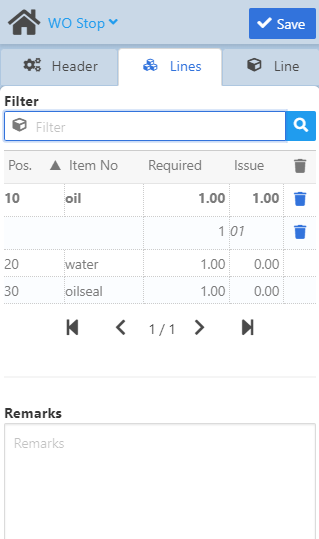

Upon tapping the "Stop work" button for an operation in the list, the app switches to the Lines tab which displays the individual WO positions of the operation in a list.

The list displays the WO positions of the operation by Position number, Item number, Required quantity and Issued quantity.

By tapping on a position, it is opened in the Line tab.

Field Descriptions

Field

|

Description

|

Filter

|

Search for an item.

WMS Integration - When working with a WMS database, and connected Produmex Add-On, the list is filtered based on the Produmex WMS Add-On > Organizational structure > Quality Status >"Can be used for production". If the "Can be used for production" field is active, this BEAS screen section only displays WMS items that were set to "Released" status in WMS.

NOTE: WMS quality status is not defined per serial number. For this reason, all serial numbers of the same LUID will be displayed in the material issue list, even if they have different WMS quality statuses. Only quantity available in an unblocked for production status can be issued.

|

|

Pos.

|

Work order position

|

Item No

|

Item number

|

Required

|

Quantity required by the Work order.

WMS SSCC/LUID information is displayed.

|

Issue

|

issued quantity in Production UoM

|

WhsCode

|

Warehouse number

|

LUID/SSCC

|

Logistic Unit number / SSCC (WMS)

|

Remarks

|

Free text.

|

|

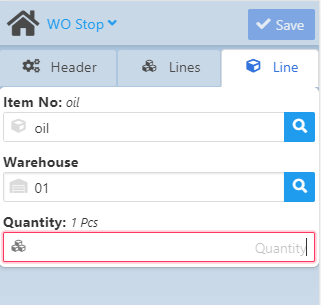

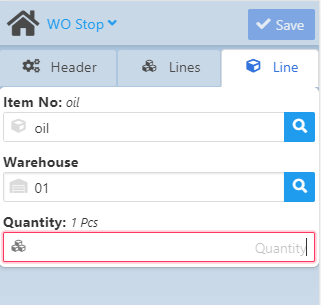

Line tab Line tab

In the Line tab it is possible to enter item-specific information for a WO-position: Item number, I-Version (if applicable), Warehouse, Bin location (if applicable), Batch/Serial information and Quantity.

The entered quantity then appears in bold font in the "Issue" column of the Lines tab (see image below).

Field Descriptions

Field

|

Description

|

Item No

|

Item number

|

Warehouse

|

|

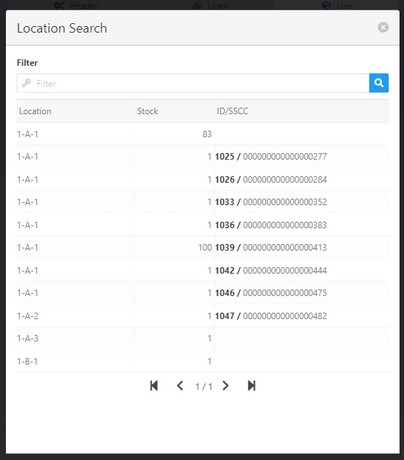

Bin Location

|

When the Warehouse for the item has been selected, this field shows the exact bin

location (if available). In case of a batch/serial-managed item, this field is

automatically filled by the system after selecting the batch/serial in the Batch/Serial

Number field.

Mobile View:

The field is only visible if the field is required.

Desktop / Tablet View:

The field is non-editable if the field is not required.

Receipt Rules

Issue Rules

Limitation of Beas Bin Management:

- RFID definition is not supported

Limitation of SAP Bin Management:

- not all Bin Rules are supported in the current view

- Weight/Volume are currently not supported in the current view

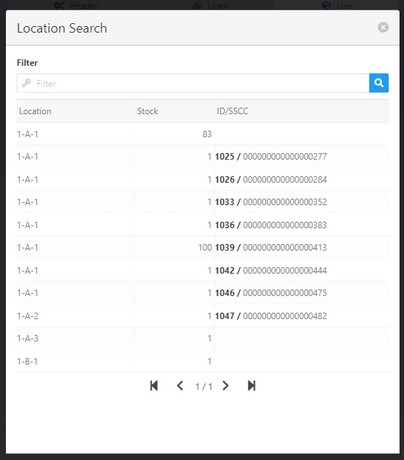

For normal items, select the Produmex WMS logistic unit of your choice in the "Location Search" screen that opens when you tap the  magnifying glass icon. magnifying glass icon.

Field

|

Description

|

Location

|

Bin Location ID

|

Stock

|

Available quantity in the bin location

|

ID/SSCC

|

LUID - logistical unit ID) - SSCC number (WMS)

|

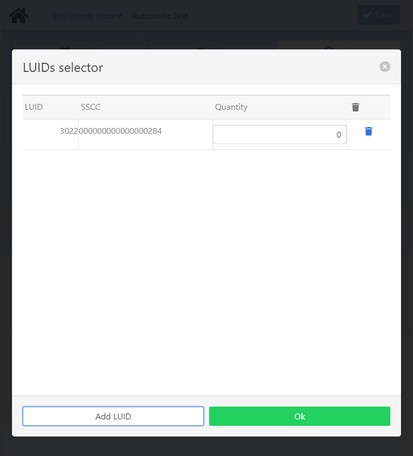

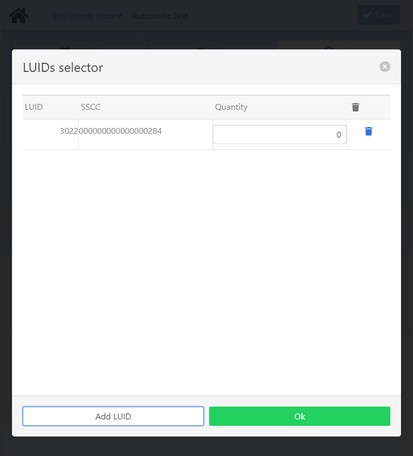

In case of WMS bin-warehouses, tap the  button to open the LUIDs selector screen to provide the LUID and button to open the LUIDs selector screen to provide the LUID and

the quantity. The screen allows to select the same item from more than one logistic unit (LUID) at a time.

Add LUID button: Add more LUIDs and close the screen with the OK button. the available number for the

selected item, LUID name and description are indicated in brackets above the field in the Line tab after you close this screen.

|

|

Batch/Serial Number

|

Batch/Serial number search.

The  opens the "Batch/Serials: Extended Information" screen. In this application you can edit Batch/Serial number, Version and Quantity fields. See other, non-editable attributes in Extended information screen. opens the "Batch/Serials: Extended Information" screen. In this application you can edit Batch/Serial number, Version and Quantity fields. See other, non-editable attributes in Extended information screen.

WMS integration: Tap the magnifying glass icon to filter by LUID.

Note: It is not possible to do so with the Batch/Serial Extended Information screen.

Mobile View:

The field is only visible if the field is required.

Desktop / Tablet View:

The field is non-editable if the field is not required.

WMS integration: Tap the  magnifying glass or magnifying glass or  to filter by LUID. to filter by LUID.

|

Quantity

|

Quantity of item indicated in Production UoM

|

In the Lines tab the  trash can icon becomes active (blue) once quantity is issued for a WO position. The issued quantity then is deletable. trash can icon becomes active (blue) once quantity is issued for a WO position. The issued quantity then is deletable.

As in other WEBapps, Remarks may be added before closing the WO position and saving the document.

|

Help URL: https://help.beascloud.com/beas202105/index.html?wo_stop.htm

|

![]() magnifying glass icon opens the "Opened work orders" screen:

magnifying glass icon opens the "Opened work orders" screen: