Imports Work order definitions.

A work order has the following objects:

| • | Work order header |

| • | Work order position |

| • | Work order bill of materials and routing position |

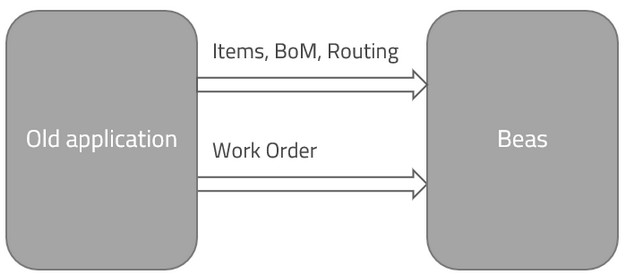

Example: The old system contains all item, bill of materials and routing information. This data can be imported with the integration hub. After this is complete, work orders can be imported. Only the top level assembly can be defined. Beas reads bill of materials and routing information from imported master data.

It is not possible to import routing or bill of materials for every work order separately.

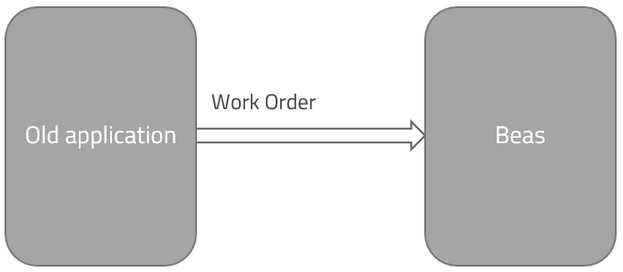

A third-party application can define the work orders in Beas. You can use this option if you have an external planning tool for production in stock.

|

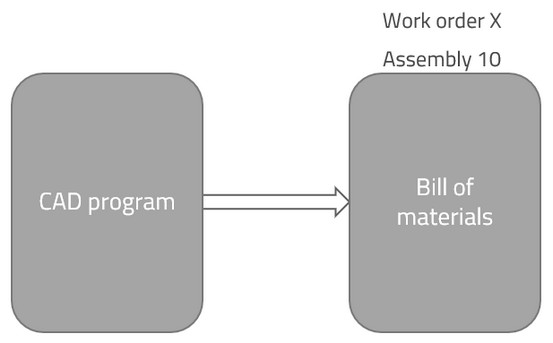

Example: A machine needs to be produced and while producing the technical planning continues. You can import and synchronize the bill of materials in the work order directly from the CAD program. |

Area |

Insert |

Update |

Work order header (BEAS_FTHAUPT) Use this if you want to update the header information or if you want to create new work orders and you need only the item code and quantity for the work order position. |

Inserts all header information. Inserts first work order position with item code and quantity. Beas explodes the bill of materials, routing position and all order-related sub-assemblies. Note: Creating reference to other documents or changing any properties in the work order line is not possible. You can change the work order type, but it is not possible to change the work order type related flags; Beas ignores these changes.

You cannot define the document number (BEAS_FTHAUPT.BELNR_ID), only the order number (BEAS_FTHAUPT.AUFTRAG). |

Most properties are changeable, but you cannot change the created work order positions.

Beas will ignore the item code and quantity property.

|

Work order position (BEAS_FTPOS) Use this to import work order positions with extended position information. The assembly can be defined, but Beas always uses the BOM and routing information from item master data. |

Add position to existing work orders. Beas explodes the bill of materials, routing position and all order-related sub-assemblies. If you do not define a work order number, Beas creates a new work order (BELNR_ID=0). It is not possible to define additional information for work order header if the system creates a new work order.

Defines linked information. |

It is not possible to update existing positions. |

Bill of materials (BEAS_FTSTL) Use this to synchronize the BOM with external programs. you can add and change bill of materials position of existing work order positions. |

The work order document number, work order position and bill of materials position are mandatory.

When trying to insert an exiting BOM position, Beas updates the position.

Beas does not explode order related assemblies. Multilevel work orders cannot be created. |

All properties of an existing bill of materials position can be updated.

Beas does not change existing sub-position.

You can delete a BOM if you set the quantity to 0, but only if no related transaction or reservation exists. |

Routing position |

Not possible. |

Not possible. |

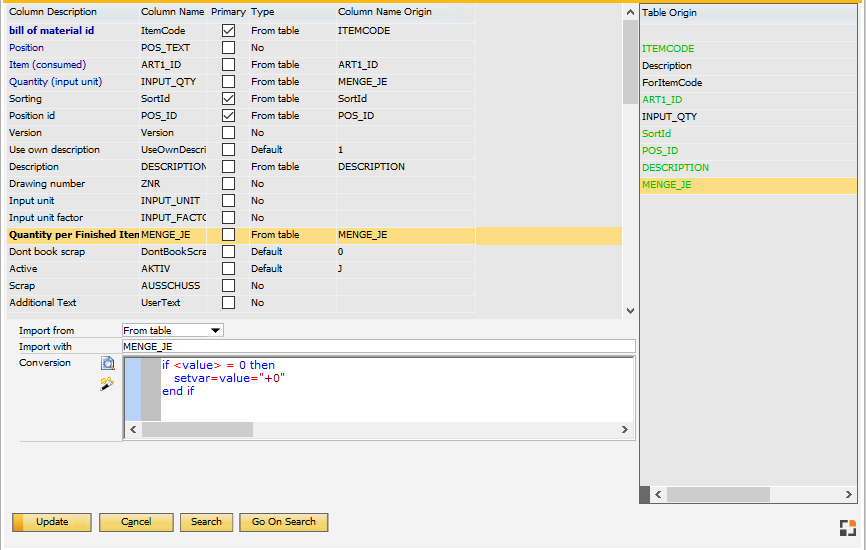

Imports Work Order Bill of Materials definitions. The following fields are mandatory:

Entries can only be changed if changes are allowed and the work order position is not closed.

Position numbers:

Position text:

ItemCode: Item code is mandatory and the item must exist. The integration hub does not check additional rules. If you change the item and the related position, reservation or transactions exist, Beas does not change anything. Note: If you insert an order-related item, Beas does not create an order-related sub-position.

ItemVersion: The system check, if the Item Version is existing and not locked But it's allowed to use it, if not released.

Quantity: Rules for quantity in the BOM import:

Delete a bill of materials position: It is possible to delete an existing Bill of materials position. Beas requires the following fields: BELNR_ID,BELPOS_ID and POS_ID and Quantity=0.

Sorting (SortId): Defines the sorting for the bill of materials positions. You can define a positive number or special sorting rules.

|