Overview on all positions of this work order. The list is sorted by structure, in the same way as work order structure view. Window settings and Templates are supported.

For some fields, editing can be activated. There is no automatic scheduling when dates are changed. For field descriptions see Edit WO position.

Functions

Field |

Meaning |

Open |

Open work order item. |

Add |

Create new work order item. |

Remove |

Delete all marked items or the currently selected one. Deletion is possible only if there are no postings or time receipts. |

Post-calculation |

Post-calculation for the currently selected item. (No multiple selection) |

Material requirement |

Material requirement for all marked rows or the currently selected one. |

The following additional columns can be selected via window settings.

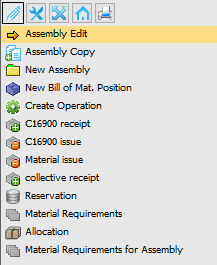

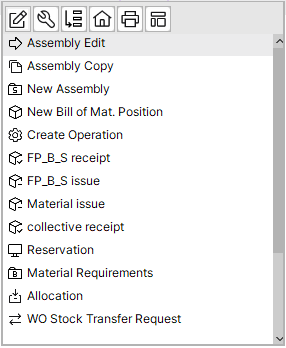

Right-click basic functions for open and closed work order positions

Traditional style |

Boyum Style |

|---|---|

|

|

Functions

Option |

Description |

|---|---|

Assembly Edit |

Opens the work order position to edit. |

Assembly Copy |

Copy the work order position to the clipboard. After selecting Assembly Copy, the Assembly: Insert function is available when right-clicking on work orders and work order positions. The Assembly: Insert function creates the copied assembly inside the selected document. |

New Assembly |

Opens a Work order position window to create a new work order position. |

New Bill of Mat. Position |

Opens a Bill of Materials window to create a new Bill of materials position for the selected work order position. |

Bill of Materials Item XX Delete |

If there are documents (e.g. Reservation) linked to the selected BoM position, you can only delete the BoM position if you delete the linked documents first. |

Create Operation |

Opens the Operation window to create a new routing position for the selected work order position. |

Product Receipt |

Opens the Receipt window to create a production receipt for the item that is produced in the work order position. |

Product Issue |

Opens the Issue window to create a material issue for the item that is produced in the work order position. |

Material Issue |

Opens the Issue window to create materials issues for all the components related to the Bill of materials of the work order position. |

Collective Receipt |

Opens the Collective Receipt window to create multiple production receipts for the selected work order position. |

Reservation |

Opens the Reservation window to create materials reservations for all the components related to the Bill of materials of the work order position. |

Material Requirements |

Opens the Material Requirements report for the selected work order position. |

Allocation |

Opens the Allocation window to create materials allocations for all the components related to the Bill of materials of the work order position. |

Material Requirements for Assembly |

Opens the Material Requirements for Assembly window and lists all assemblies. |

Invent. History |

Opens the Inventory History report for the selected work order position. |

Assembly, Bill of Materials, Routing |

Expands the selected work order position to show Bill of materials, routing for the work order position and all its sub-assemblies. |

Search for Structure |

Opens the Search for Structure window that allows searching for a specific component in the selected work order positions and their sub-assemblies. If the component is found, the containing assembly position is expanded, and its line is highlighted. |

Reservation |

Opens the Reservation window, but creating a new reservation is not allowed when the work order position is closed. |

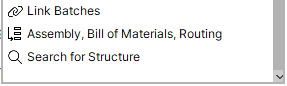

Link Batches |

Opens the Link Serial Numbers / Batches window. This function allows linking the consumed batches or serial numbers of raw materials to the produced batches or serial numbers to enhance traceability functions. |

Assembly, Bill of Materials, Routing |

Expands the selected work order position to show Bill of materials, routing for the work order position and all its sub-assemblies. |

Search for Structure |

Opens the Search for Structure window that allows searching for a specific component in the selected work order positions and their sub-assemblies. If the component is found, the containing assembly position is expanded, and its line is highlighted. |

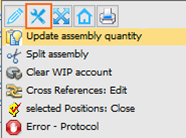

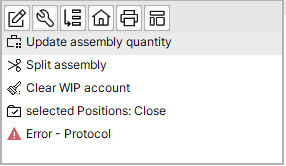

Right-click extended functions work order positions

Traditional style |

Boyum Style |

|---|---|

|

|

Option |

Description |

|---|---|

Update Assembly Quantity |

Allows changing the quantity of the assembly and then recalculates the corresponding quantity for the sub-assembly. This function only recalculates the first sub-assembly, therefore it should not be used when a work order position has more than one linked sub-assembly. |

Split Assembly |

Splits the selected work order position into two assembly positions but does not split the sub-assemblies related to the selected work order position. When performing the split of the assembly, all existing material reservations are removed, but the existing serial number reservations are maintained and split among the assemblies. A window opens where the serial number reservations can be assigned to each assembly. The split process does not consider the Lot Size field when creating the new work order positions. |

Clear WIP Account |

Creates a journal entry to clear the existing balance of the work in progress account for the selected work order position. |

Cross References: Edit |

Opens the Cross Reference - Edit window. Here you can edit the documents linked to the selected work order position. |

Selected Positions: Close |

Closes the selected work order position. |

Error - Protocol |

Displays all the protocols and error messages for the selected work orders. If the work order has an error message, the Status Error Delete option is also available. The Status Error Delete option deletes all error messages for the work order. |