QCOrder

QCOrder

Property |

Description |

Table |

BEAS_QSFTHAUPT |

Primary key |

DocEntry/i |

$transaction |

no |

$branch |

no |

$mask |

no |

Fields

Name |

Type |

Description |

|

DocEntry |

Edm.Int32 |

|

|

DocOrder |

Edm.String(20) |

|

|

DocOrder2 |

Edm.Int32 |

|

|

DocDate |

Edm.DateTimeOffset |

|

|

ItemCode |

Edm.String(50) |

|

|

ItemName |

Edm.String(255) |

|

|

IVersionId |

Edm.String(20) |

|

|

DrawingNumber |

Edm.String(50) |

|

|

WhsCode |

Edm.String(20) |

|

|

Quantity |

Edm.Decimal |

|

|

UoMStock |

Edm.String(1) |

|

|

ItemInfo |

Edm.String(16000) |

|

|

DistNumber |

Edm.String(40) |

|

|

QCInspectionPlanId |

Edm.String(20) |

|

|

ParentQCOrder |

Edm.String(20) |

|

|

ItemQcLinkId |

Edm.Int32 |

|

|

RuleId |

Edm.String(20) |

|

|

Type |

Edm.String(1) |

|

|

BaseType |

Edm.String(20) |

|

|

BaseDocEntry |

Edm.Int32 |

|

|

BaseDocOrder |

Edm.String(20) |

|

|

BaseLineNumber |

Edm.Int32 |

|

|

BaseLineNumber2 |

Edm.Int32 |

|

|

CardCode |

Edm.String(20) |

|

|

PrjCode |

Edm.String(20) |

|

|

PrjUID |

Edm.Int32 |

|

|

CreatedUserSign |

Edm.Int32 |

|

|

CreatedPersonellId |

Edm.String(20) |

|

|

CreatedBeasVersion |

Edm.String(20) |

|

|

CreatedStation |

Edm.String(40) |

|

|

WoDocEntry |

Edm.Int32 |

|

|

WoLineNumber |

Edm.Int32 |

|

|

WoLineNumber2 |

Edm.Int32 |

|

|

SamplesOpen |

Edm.Int32 |

|

|

SamplesOK |

Edm.Int32 |

|

|

SamplesError |

Edm.Int32 |

|

|

PrintStatus |

Edm.Boolean |

|

|

MaterialTransfer |

Edm.Int32 |

|

|

Release |

Edm.Boolean |

|

|

ReleasePersonnelId |

Edm.String(20) |

|

|

ReleasePersName |

Edm.String(20) |

|

|

ReleaseStationId |

Edm.String(20) |

|

|

ReleaseDate |

Edm.DateTimeOffset |

|

|

ValuationId |

Edm.String(20) |

|

|

ValuationText |

Edm.String(255) |

|

|

BlockageReasonId |

Edm.String(20) |

|

|

BlockageReasonText |

Edm.String(16000) |

|

|

Closed |

Edm.Boolean |

|

|

CloseDate |

Edm.DateTimeOffset |

|

|

ClosePersonellName |

Edm.String(50) |

|

|

Picture1 |

Edm.String(100) |

|

|

Picture2 |

Edm.String(100) |

|

|

Picture3 |

Edm.String(100) |

|

|

UDF1 |

Edm.String(100) |

|

|

UDF2 |

Edm.String(100) |

|

|

UDF3 |

Edm.String(100) |

|

|

UDF4 |

Edm.String(100) |

|

|

UDF5 |

Edm.String(100) |

|

|

UDF6 |

Edm.String(100) |

|

|

UDF7 |

Edm.String(100) |

|

|

UDF8 |

Edm.String(100) |

|

|

UDF9 |

Edm.String(100) |

|

|

UDF10 |

Edm.String(100) |

|

|

UDF11 |

Edm.String(100) |

|

|

UDF12 |

Edm.String(100) |

|

|

UDF13 |

Edm.String(100) |

|

|

UDF14 |

Edm.String(100) |

|

|

UDF15 |

Edm.String(100) |

|

|

LastChangeDate |

Edm.DateTimeOffset |

|

|

LastChangeUserId |

Edm.String(20) |

|

Relations

Join to Entiy Object |

Relation |

Item |

ItemCode |

UoM |

UoMCode=UoMStock |

QCOrderSamples |

DocEntry |

QCOrderMeasurement |

DocEntry |

QCOrderAttachment |

DocEntry |

DocumentBatchSerial |

BaseType=DocType,BaseDocEntry=DocEntry,BaseLineNumber=LineNumber |

Functions

Function |

Parameter |

Description |

|

GetInspectionPlan |

Type/c,ItemCode/c,Version/c,CardCode/c,Quantity/n,WhsCode/c,Date/d |

||

CreateQcOrderLockedBatches |

|

||

CreateQcOrder |

Type/c,DocEntry/i,BaseDocEntry/i,BaseLineNumber/i,BaseLineNumber2/i |

|

|

CreateQcOrderFromGoodsReceiptPO |

DocEntry/i |

|

|

CreateQcOrderFromSAPDocument |

DocEntry/i,TableName/c |

|

|

CreateQcOrderFromSAPDocumentDirect |

DocEntry/i,TableName/c |

|

|

CheckRelease |

DocEntry/i |

|

|

ReleaseQcOrder |

DocEntry/i |

|

|

CloseQcOrder |

DocEntry/i |

|

|

CreateSample |

DocEntry/i |

|

|

QCOrderBatches |

DocEntry/i |

|

|

TransferLoad |

DocEntry/i |

|

|

TransferGetWareHouse |

DocEntry/i,Rejected/b |

|

Changeable fields (PUT)

Follow fields changeable

UDF1...UDF15, BlockageReasonId,BloackageText,ValuationId,ValuationText,iteminfo,Release,Closed

Example:

put QCOrder(1407)

{"BlockageReasonId":"WrongColor"}

Note:

Send parameter in correct order. First the Id and then the Text.

If you send an ID, the system insert the default Text information and with next property you can overwrite it

Example: Overwrite standard BlockageReason Text:

put QCOrder(1407)

{"BlockageReasonId":"WrongColor","BlockReasonText":"This is my own Text"}

Release and Closed:

Correct order is: Fill all other fields then Release and at end the Closed information.

Relation DocumentBatchSerial

This allow to link to BatchNumber/SerialNumbers related to SAP Document Only working, if QC order is linked to SAP Document get all related BatchNumbers for QC Order 1392

For this we use the middle Object "DocumentBatchSerial", which return all linked Batch and Serial SystemNumbers.

get QCOrder?$select=DocumentBatchSerial/ItemCode,DocumentBatchSerial/SystemNumber, DocumentBatchSerial/BatchNumber/Batch&$filter=DocEntry eq 1392 and BaseType lt 'A'

Note: This is not working, if the QC order was created manually without reference to a SAP document.

Good alternative: Use get QCOrder/QCOrderBatches(DocEntry) This function return all Batches. Not compatible to SerialNumbers. |

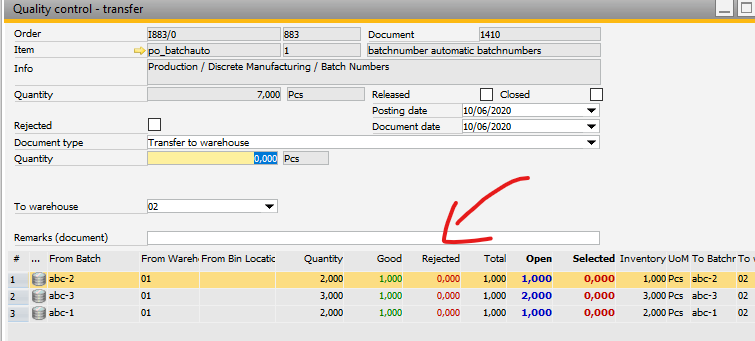

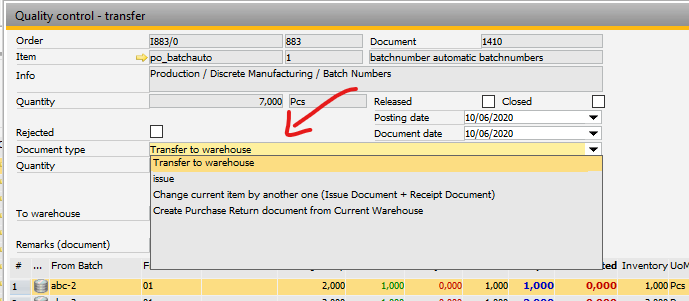

Manage transfer process It is possible to - create transfer, - issue, - move from on item to another item / Batch / bincode - create Po Return docuemtn

Only possible for lines, which the QCOrder/TransferLoad() function will return Primary key is the BatchNumber and BinCode If all items booked, the system close automatically the transfer process

Load Transfer Lines

get QCOrder/TransferLoad(DocEntry) This return all lines, which are open

To post the Transfer (all document types) you must send the lines in follow way post QCOrder {"transfer":{ "DocEntry":1000, "PostingDate":..., "DocumentDate":..., "Remarks":"...", "Ref":"...", "DocumentLines": [ {DistNumber":"...", "BinCode":"..","DocType":0-3,"Quantity":x,"Reijected":true/false,"ToQuantity":x,"ToItemCode","ToBinCode":"",ToDistNumber":"","ToWhsCode":""},{...} }

{ "TransferDocEntry":x, "TransferDocNumber":x, "ReceiptDocEntry":x, "ReceiptDocNumber":x, "PoReturnDocEntry":x, "PoReturnDocNumber":x "CloseTransfer":true/false } Every entry only, if a document is created for this type. Example: If only a transfer document was created, it return { "TransferDocEntry":x, "TransferDocNumber":x, }

The System check, if all items transfered. If yes, it return"CloseTransfer":true otherwise false |