The requirement coverage calculation checks which components are required for a sales order:

The MRP always breaks down the assembly requirements (eg. from customer orders). If the sub-requirement (BOM of an assembly) is again an assembly, it is first checked whether this can be covered by stock or by planned inflow. If not, this is broken down further. For this, during the computation, the planned inflow is temporarily assigned to the planed outflow.

The following inflow is considered in order:

| 1. | Remains from order multiples |

| 2. | Inventory |

| 3. | Production receipts, ascending by date of receipt |

| 4. | Purchase receipts, purchase and production requests, ascending by date of receipt |

Note: The system ignores the Item-Version.

Temporary reservation that is set up here, is valid only at the moment of computation and should not be confused with a fixed reservation. The temporary reservation is made at a time, when it is not yet known which material is actually needed. The computation is performed at this moment. At the time of computation, there is no balance, so this can not be considered. Therefore, the program uses a different priority for the temporary reservation:

| 1. | Minimum inventory |

| 2. | Existing production outflow (BOM) of work orders and planned orders |

| 3. | Customer orders, advance invoices, forecasts with setting "like customer order" |

| 4. | Transfer Requests |

| 5. | Forecasts (Default) |

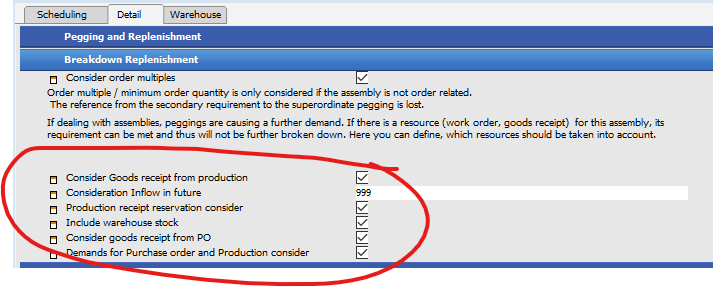

You can define this in MRP Detail - Breakdown - Replenishment

The temporary reservation determines, whether sub-assemblies are broken down any further. The assigned planned inflow does not cover the requirement of a planned outflow.

In case of working with fix reservations, when the reserved material is always firmly linked to a pegging and it may not be assigned to another pegging.

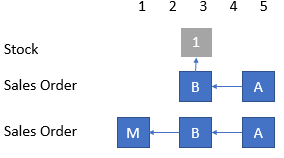

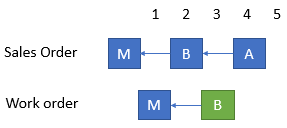

Example: Item A has stock related Sub Assembly B with Material M

We've 2 sales order, same item, same quantity with same delivery date and only B has stock 1 Pcs

In this case the first Sales order create a requirement for B, but the system coverage this temporaly with Stock

For second sales order no stock for "B" is available and the system check, which material you need to produce B. In this case it create a requiremet for Material M

Result:

Saldo A: 2

Saldo B: 1

Saldo M: 1

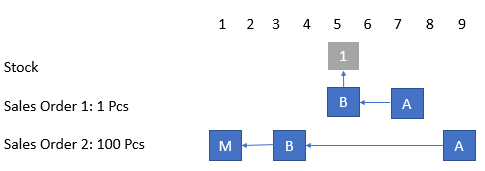

Problem with Balance im time line from sub assembly:

Sales order 1: 1 Pcs, Delivery Date: 5th

Sales order 2: 100 Pcs, Delivery Date: 7th (later)

This produce different duration for the requirement of sub assembly b, because you need more time for production of Sales order A

The system calculate Sales order 1 and coverage the stock for stock related assembly "B"

Then the system calculate Sales order 2 and no stock is available. The system simulate the production for B and create the Material requirement for Sales order 2

In Saldo List for B you see

stock related item "B" |

Date |

Issue |

Balance |

Sales order 2 |

3th |

100 |

-99 |

Sales order 1 |

5th |

1 |

-100 |

and for Material

stock related item "B" |

Date |

Issue |

Balance |

Sales order 1 |

1th |

100 |

-100 |

That's mean: in the result you see the requirement in another order as at calculation time.

Same situation for priority of calculation: Minimum inventory, work order, Sales order and so on. The time line while calculation of coverage has priority 2.

Note: If you use a precalculation inside a sales order, the production time is always 0, because the precalculation don't calculate the production time

Note:

All production receipts are taken into consideration, regardless of the warehouse they are posted to. Warehouse settings defined in Planning scenarios – Warehouse are not considered here.

The temporary reservation can be displayed even after the computation in Order recommendation report > Origin.

In this list all temporary links are displayed in a structure view. See origin of requirement structure.

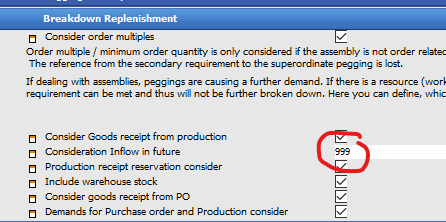

Consider inflow in future

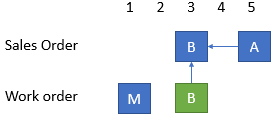

If the date of delivery would be taken into consideration, the following problem could occur:

Assembly A contains assembly B with material M1.

Sales Order: assembly A on May 5th

Requirement of assembly B at May 3th and material M1 at May 1th.

Work order is created for May 3th, material is ordered for May 1 th.

All requirements are covered.

The customer asks for a delivery one day earlier on May 4th:

If the requirement coverage calculation would take into account the delivery date, then the work order would no longer cover the requirement.

In effect, assembly B would be broken down, although the balance is 0. From the work order and the sales order a requirement would arise for material M1 - and thus it would be ordered twice.

To prevent this, the delivery date is not considered.

The delivery date is taken into account, but it may be in the future. This is set up in Configuration wizard – Detail – Breakdown replenishment – Consideration of future receipt.

The delivery date is not taken into account - except for point 1 - since otherwise there would be a risk that the sub-material is dispatched twice. For this reason, Configuration wizard – Detail – Breakdown replenishment – Consideration of future receipt parameter is set to 99 days.

If Consider inflow in future is activated the system coverage the work order, which is 1 day in future and you need in the example the Material "M" only 1 time.

Filter Only shortage

This filter shows all items, which need to be ordered or produced or for which the planned inflow is too late.

In this case, assembly B would be shown as shortage, as the balance for 4th May is negative.

The inflow to be used, can be specified in MRP wizard > Detail > Breakdown of resources.